Coated member and making method thereof

A technology of coating parts and antibacterial layers, which is applied in the field of coating parts and its preparation, can solve the problems of easy breeding of bacteria and other microorganisms, and achieve good antifouling and antibacterial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

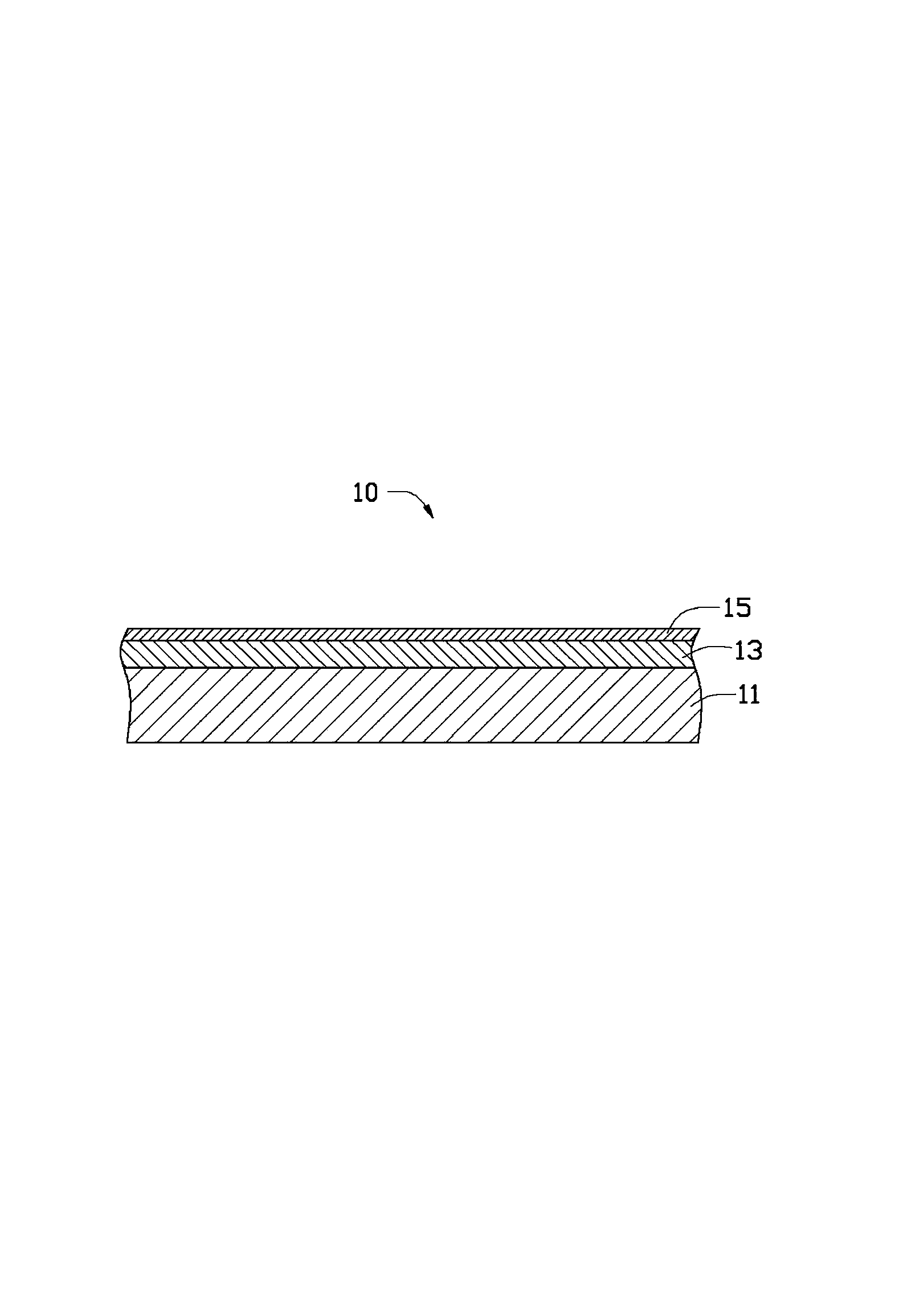

[0021] The preparation method of coating member 10 of the present invention, it comprises the steps:

[0022] (1) Add the antibacterial material to the organic solvent to disperse the colloid. The antibacterial material contains at least one of nano-silver ions, nano-copper ions, and at least one of nano-titanium dioxide, nano-zinc oxide, and nano-copper oxide. The organic solvent is preferably ethanol, but not limited to ethanol. The mass ratio of the antibacterial material to the organic solvent in the colloid is 1:1-1:100.

[0023] (2) Mix the above-mentioned colloid with silicon oxide having nanoscale pores, remove the organic solvent, and perform heat treatment to obtain a nanocomposite material. The heat treatment is at 300-500° C. for 0.5-5 hours. The antibacterial material in the nanocomposite material is loaded on silicon oxide, which can greatly improve the utilization rate of the antibacterial material. The mass of the antibacterial material contained in the col...

Embodiment 1

[0032] The antibacterial material is added into an organic solvent to disperse the colloid. The antibacterial material contains nano-silver ions and nano-titanium dioxide. The organic solvent is ethanol, and the mass ratio of the antibacterial material to the organic solvent is 1:50.

[0033] The above colloid was composited with silicon oxide with nanoscale pores, and the organic solvent was evaporated to remove the organic solvent. Then, the temperature was raised to 400°C in a muffle furnace for 2 hours to prepare a nanocomposite material, in which the mass of the antibacterial material was 2.0% of the mass of the silicon oxide.

[0034] The material of the substrate 11 used in this embodiment is glass.

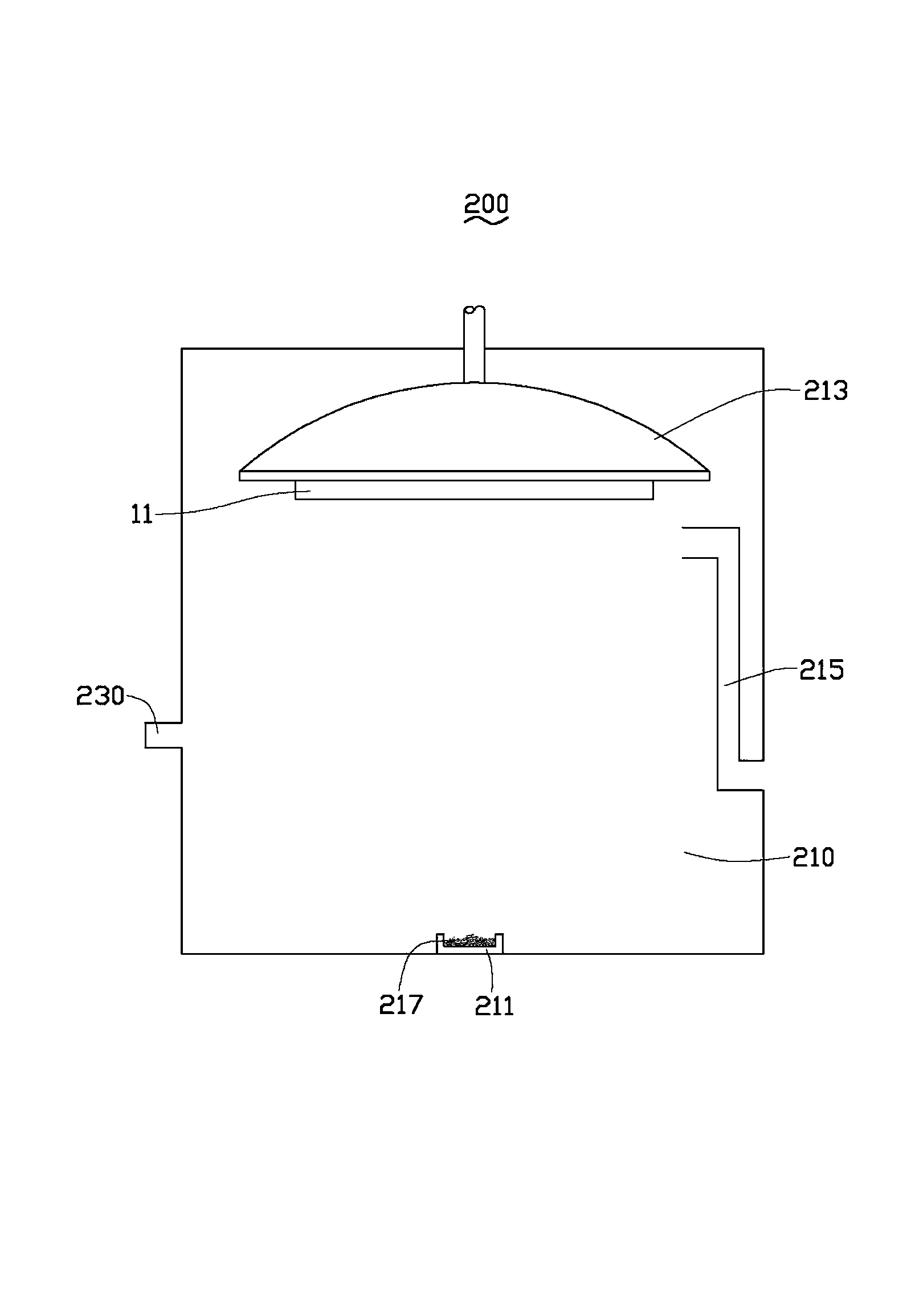

[0035] Adopt the method for evaporative coating, deposit nano-composite material on the surface of base material 11 to form an antibacterial layer 13, the vacuum tightness in the vacuum evaporation machine is set to be 5 * 10 -5 torr, the temperature is 80° C., and the com...

Embodiment 2

[0043] The antibacterial material is added into an organic solvent to disperse the colloid. The antibacterial material contains nano-silver ions and nano-titanium dioxide. The organic solvent is ethanol, and the mass ratio of the antibacterial material to the organic solvent is 1:100.

[0044] The above colloid was combined with silicon oxide with nanoscale pores, and the organic solvent was evaporated to remove the organic solvent. Then, the temperature was raised to 350 ° C in a muffle furnace for 2.5 hours to prepare a nanocomposite material, in which the mass of the antibacterial material was 2.5% of the mass of the silicon oxide.

[0045] The material of the substrate 11 used in this embodiment is glass.

[0046]Adopt the method for evaporative coating, deposit nano-composite material on the surface of base material 11 to form an antibacterial layer 13, the vacuum tightness in the vacuum evaporation machine is set to be 5 * 10 -5 torr, the temperature is 70°C, and the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com