Modified bitumen waterproof coiled material, coating material and preparation method thereof

A technology of waterproofing membrane and modified asphalt, applied in the direction of asphalt material binder, asphalt layered products, chemical instruments and methods, etc., can solve the problems of cracking, high temperature flow flexibility, hard and brittle, etc., and achieve excellent bonding Performance, strong and durable bond, the effect of non-diminishing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

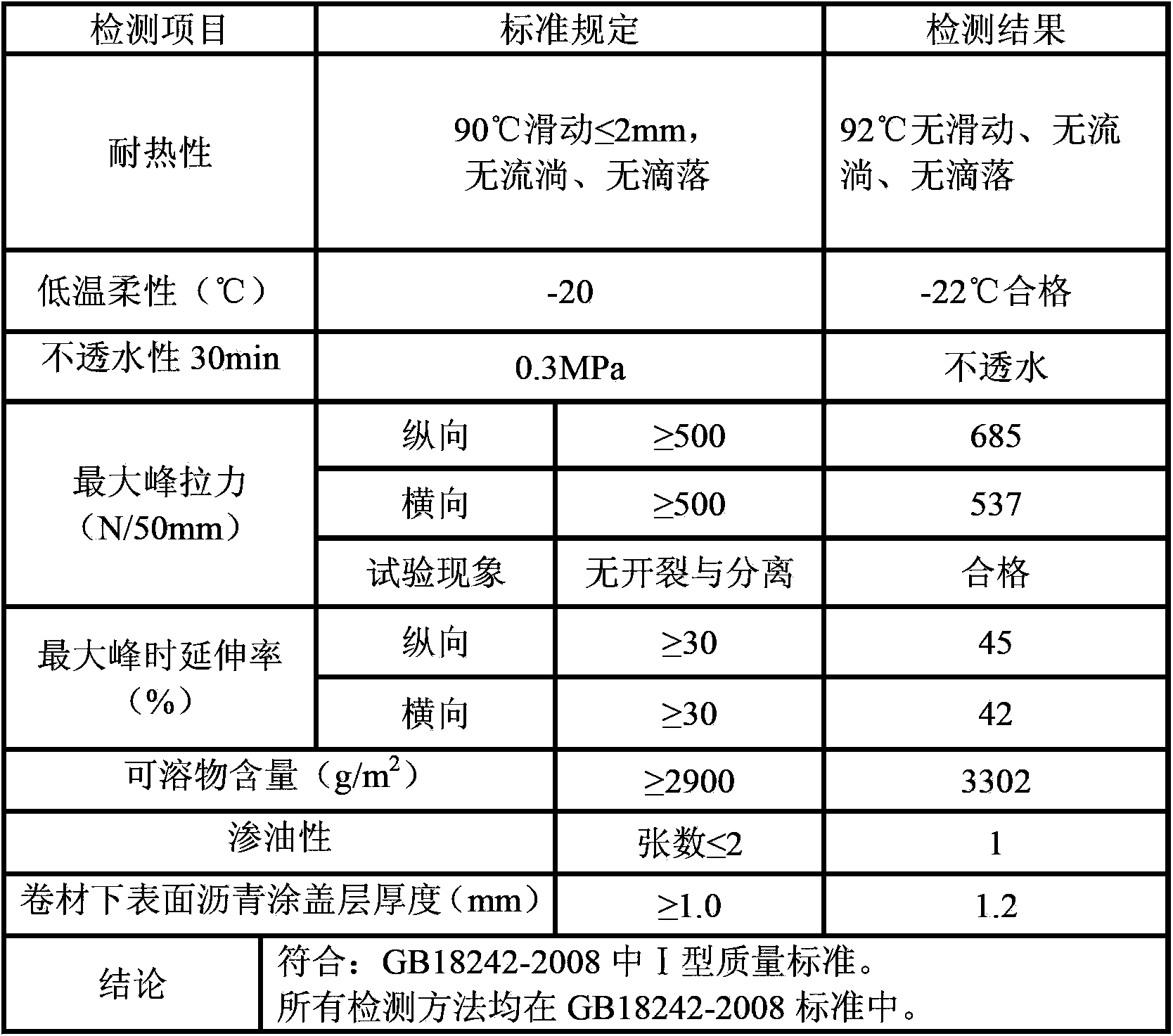

Examples

Embodiment 1

[0035] Preparation of modified asphalt waterproof membrane coating material: add 52% asphalt and 11% engine oil, heat up to 160°C for dehydration for 1 hour, add 15% SBS synthetic rubber, start the colloid mill for grinding, and control the temperature at 180°C to 200°C Grind for 1 hour at ℃, then add 5% polypropylene and continue grinding for 0.5 hour; add 5% recycled resin of bisphenol A epoxy resin (epoxy equivalent is 182 g / equivalent, particle size is 80 mesh), and finally add 7% glue powder (30 mesh) and 5% ground calcium carbonate powder (180 mesh), you can.

[0036] Preparation of modified asphalt waterproof membrane: use long-fiber polyester non-woven fabric as the base, soak with pre-impregnated oil (96% asphalt and 4% polypropylene), squeeze dry, and then coat the aforementioned coating material on both sides , coated with PE film, cooled to below 45°C, rolled, rolled and cut, and packaged to obtain a 3mm thick modified bitumen waterproof membrane.

Embodiment 2

[0038] Preparation of modified asphalt waterproof membrane coating material: add 45% asphalt and 15% engine oil, heat up to 160°C for dehydration for 1 hour, add 12% SBS synthetic rubber, start the colloid mill for grinding, and control the temperature at 180°C to 200°C After grinding for 1 hour at ℃, add 5% polypropylene and continue grinding for 0.5 hours; add 8% bisphenol A epoxy resin regenerated resin (epoxy equivalent is 244 g / equivalent, particle size is 100 mesh), and finally add 9% glue powder (50 mesh) and 6% ground calcium carbonate powder (200 mesh), you can.

[0039] Preparation of modified asphalt waterproof membrane: use long-fiber polyester non-woven fabric as the base, soak with pre-impregnated oil (96% asphalt and 4% polypropylene), squeeze dry, and then coat the aforementioned coating material on both sides , coated with mineral granules, cooled to below 45°C, rolled, rolled and cut, and packaged to obtain a 5mm thick modified bitumen waterproof membrane.

Embodiment 3

[0041] Preparation of modified asphalt waterproof membrane coating material: add 40% asphalt and 15% engine oil, heat up to 160°C for dehydration for 1 hour, add 18% SBS synthetic rubber, start the colloid mill for grinding, and control the temperature at 180°C to 200°C Grind for 1.5 hours at ℃, then add 8% polypropylene and continue grinding for 0.5 hours; add 4% bisphenol A epoxy resin recycled resin (epoxy equivalent is 182 g / equivalent, particle size is 80 mesh), and finally add 5% glue powder (30 mesh) and 10% ground calcium carbonate powder (180 mesh), you can.

[0042] Preparation of modified asphalt waterproof membrane: use long-fiber polyester non-woven fabric as the base, soak with pre-impregnated oil (96% asphalt and 4% polypropylene), squeeze dry, and then coat the aforementioned coating material on both sides , coated with PE film, cooled to below 45°C, rolled, rolled and cut, and packaged to obtain a 3mm thick modified bitumen waterproof membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com