Method for determining TOPO content in organic solvent by employing capillary gas chromatography

A technology of gas chromatography and organic solvents, which is applied in the detection field of TRPO, can solve the problems affecting the extraction effect, and achieve the effect of simple and fast method and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

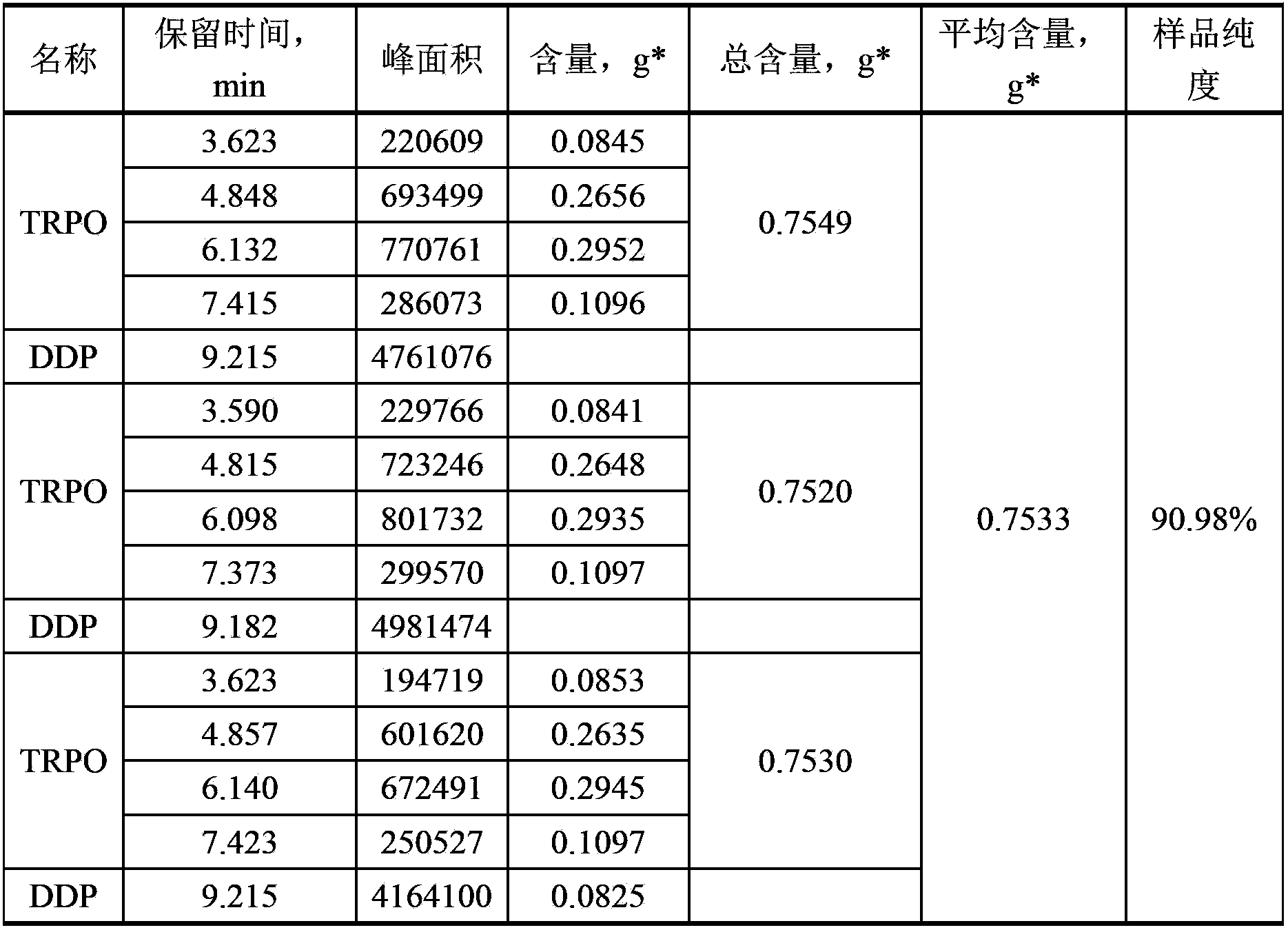

Examples

Embodiment 1

[0024] The method of capillary gas chromatography for the determination of TOPO content in organic solvents includes the following steps:

[0025] (1) Instrument connection: Connect the outlet of the Agilent 6890 gas chromatograph to the inlet of the FID hydrogen flame ion detector;

[0026] (2) Set the instrument parameters: the chromatographic column is a 30m×0.32mm fused silica capillary column, the carrier gas is high-purity nitrogen, the outlet velocity is 100ml / min, the column velocity is 4.3ml / min, and the split ratio: 23 / 1; Detector temperature is 340℃, sample inlet: 340℃, column temperature is 220℃ to 330℃, heating rate is 10℃ / min, sample injection volume: 0.2μl, 0.5μl, 1.0μl, peak area is measured by electronic integration ;

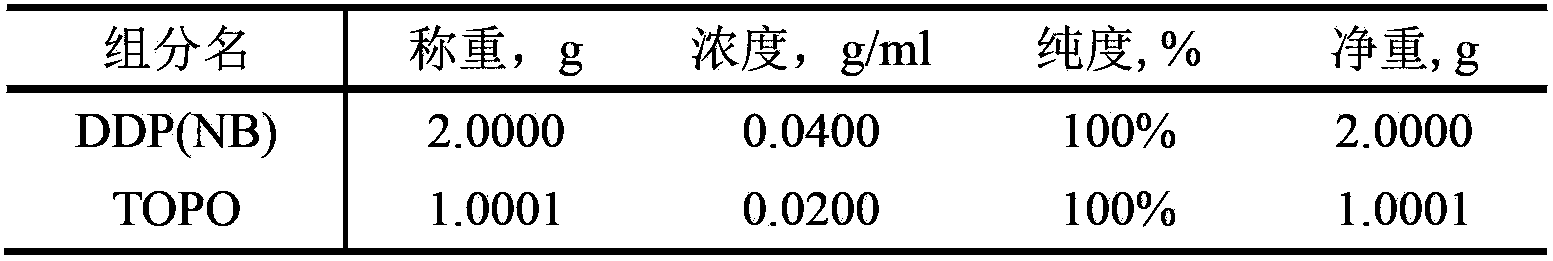

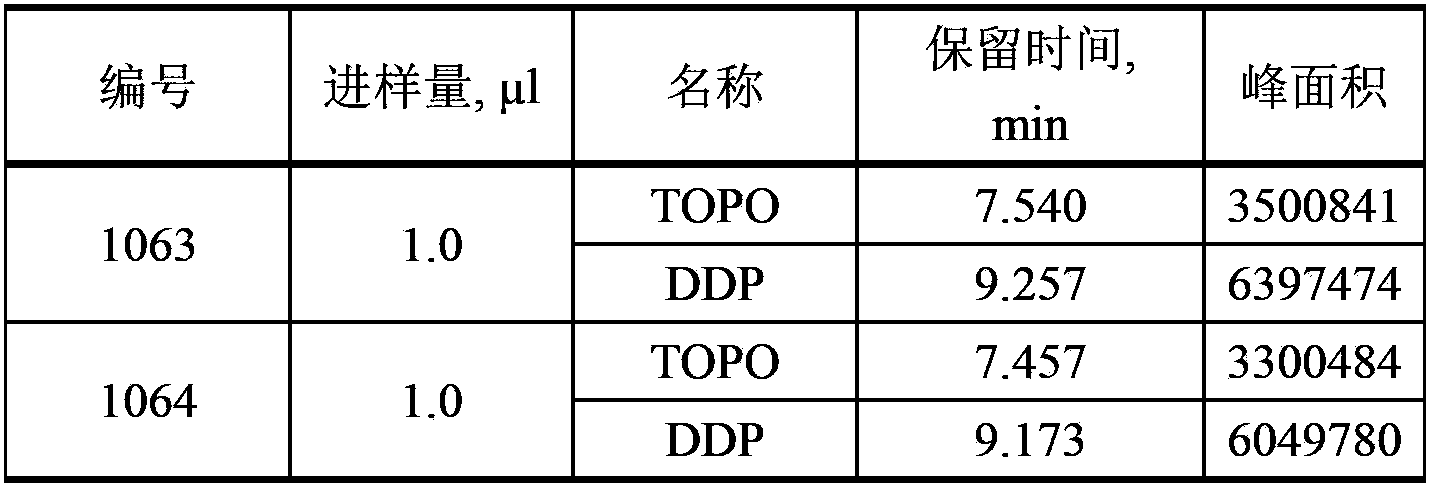

[0027] (3) Draw calibration curve:

[0028] ① Recrystallization and purification of TOPO: Weigh about 20g of industrial product TOPO, add 30-70ml of hot n-hexane to dissolve it, and let it stand for about 2 hours to recrystallize it once. Filter with...

Embodiment 2

[0044] The method of capillary gas chromatography for the determination of TOPO content in organic solvents includes the following steps:

[0045] (1) Instrument connection: Connect the outlet of the Agilent 6890 gas chromatograph to the inlet of the FID hydrogen flame ion detector;

[0046] (2) Set the instrument parameters: the chromatographic column is a 30m×0.32mm fused silica capillary column, the carrier gas is high-purity nitrogen, the outlet velocity is 100ml / min, the column velocity is 4.3ml / min, and the split ratio: 23 / 1; Detector temperature is 340℃, sample inlet: 340℃, column temperature is 220℃ to 330℃, heating rate is 10℃ / min, sample injection volume: 0.2μl, 0.5μl, 1.0μl, peak area is measured by electronic integration ;

[0047] (3) Draw calibration curve:

[0048] ① Recrystallization and purification of TOPO: Weigh about 20g of industrial product TOPO, add 30-70ml of hot n-hexane to dissolve it, and let it stand for about 2 hours to recrystallize it once. Filter with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| correlation coefficient | aaaaa | aaaaa |

| correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com