Silicon-silicon oxide-carbon composite material, lithium ion secondary battery anode material, preparation methods of two and application of composite material

A carbon composite material, silicon oxide technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of small charge and discharge capacity, low initial efficiency, low cycle capacity retention rate, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Step 1: Put 200g of SiO powder with a particle size of D50=100nm (the SiO powder produced by Shanghai Shanshan New Materials Research Institute is SS-SiO-3d, commercially available) 200g in the rotary furnace, the inner diameter of the rotary furnace is 8cm, length 0.5m. Argon is used as the protective gas, and the flow rate of argon is 0.01NL / M to prevent the oxidation of SiO powder. Raise to 700°C at a rate of 2°C / min. When the temperature rises to 700°C, acetylene is introduced. At this time, the flow ratio of acetylene to argon is 1:3. After 2 hours of heat preservation, the reactor cools down to room temperature naturally. The resistivity value measured by the four-probe method is 3.132mΩ.mm.

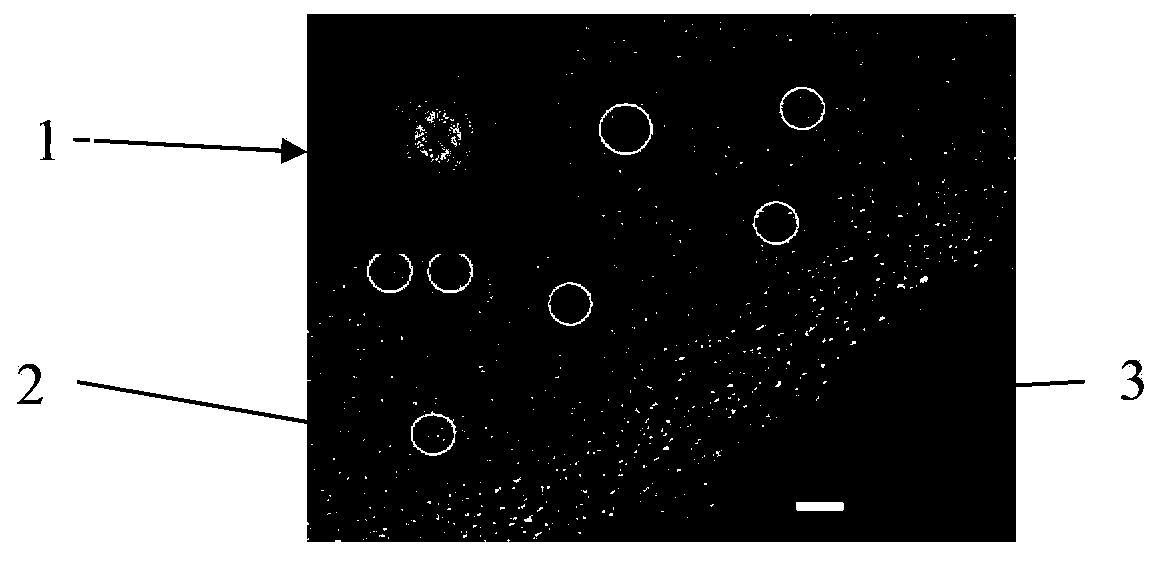

[0070] The characterization method of this structure, first cut the primary particle with FIB, and observe its cross-section through TEM, the results are as follows figure 1 As shown, 1 represents elemental silicon particles; 2 represents the selected electron diffraction...

Embodiment 2

[0080] step 1:

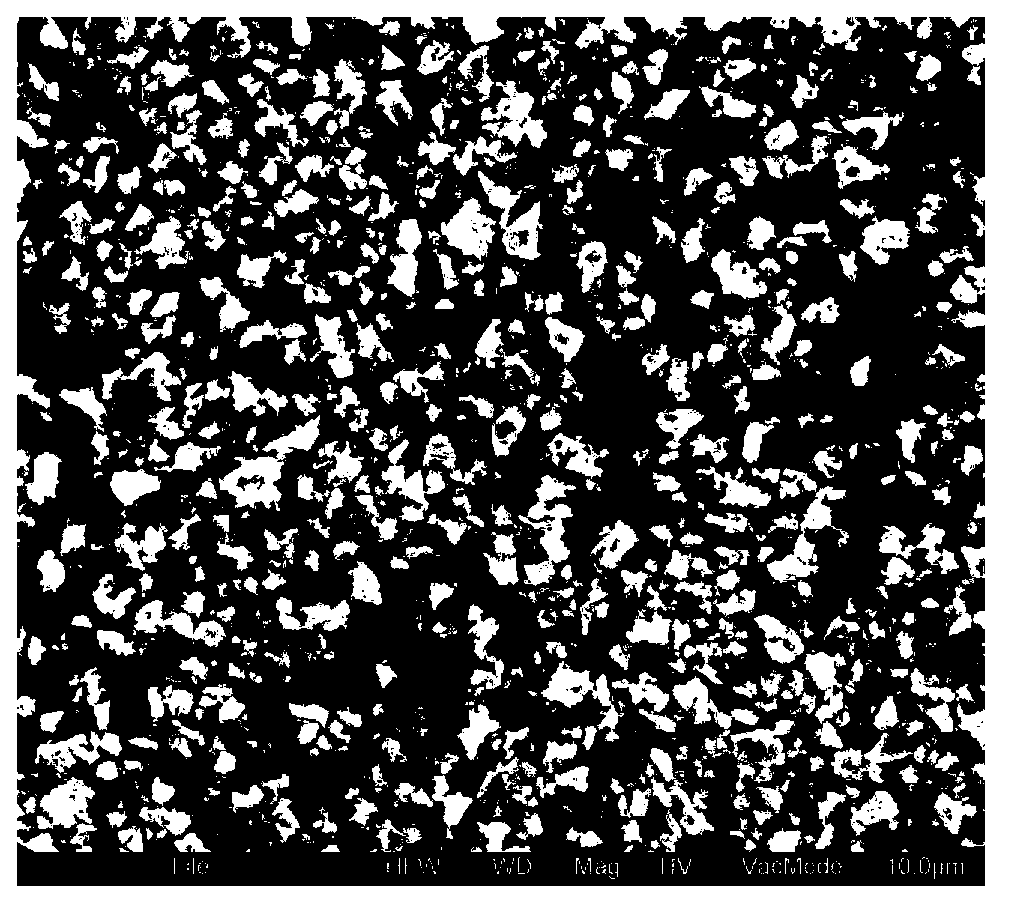

[0081]Put 200 g of SiO powder with a particle size of D50 = 1 μm (the SiO powder of Shanghai Shanshan Advanced Materials Research Institute is SS-SiO-3e, commercially available) in a rotary furnace with an inner diameter of 8 cm and a length of 0.5 m. Argon is used as the protective gas, and the flow rate of argon is 0.01NL / M to prevent the oxidation of SiO powder. Raise to 700°C at a rate of 2°C / min. When the temperature rises to 700°C, acetylene is introduced. At this time, the flow ratio of acetylene to argon is 1:3. After 2 hours of heat preservation, the reactor cools down to room temperature naturally. The resistivity value measured by the four-probe method is 10.856mΩ.mm. The cross-section of the sample was observed with an electron microscope, and the thickness of the first amorphous carbon layer was measured to be 10 nm.

[0082] The operation steps of step 2 and step 3 are the same as the operation steps of step 2 and step 3 in embodiment 1. Th...

Embodiment 3

[0086] The preparation method is the same as that of Example 1. For the physical properties of the silicon-silicon oxide-carbon composite material, refer to Example 1.

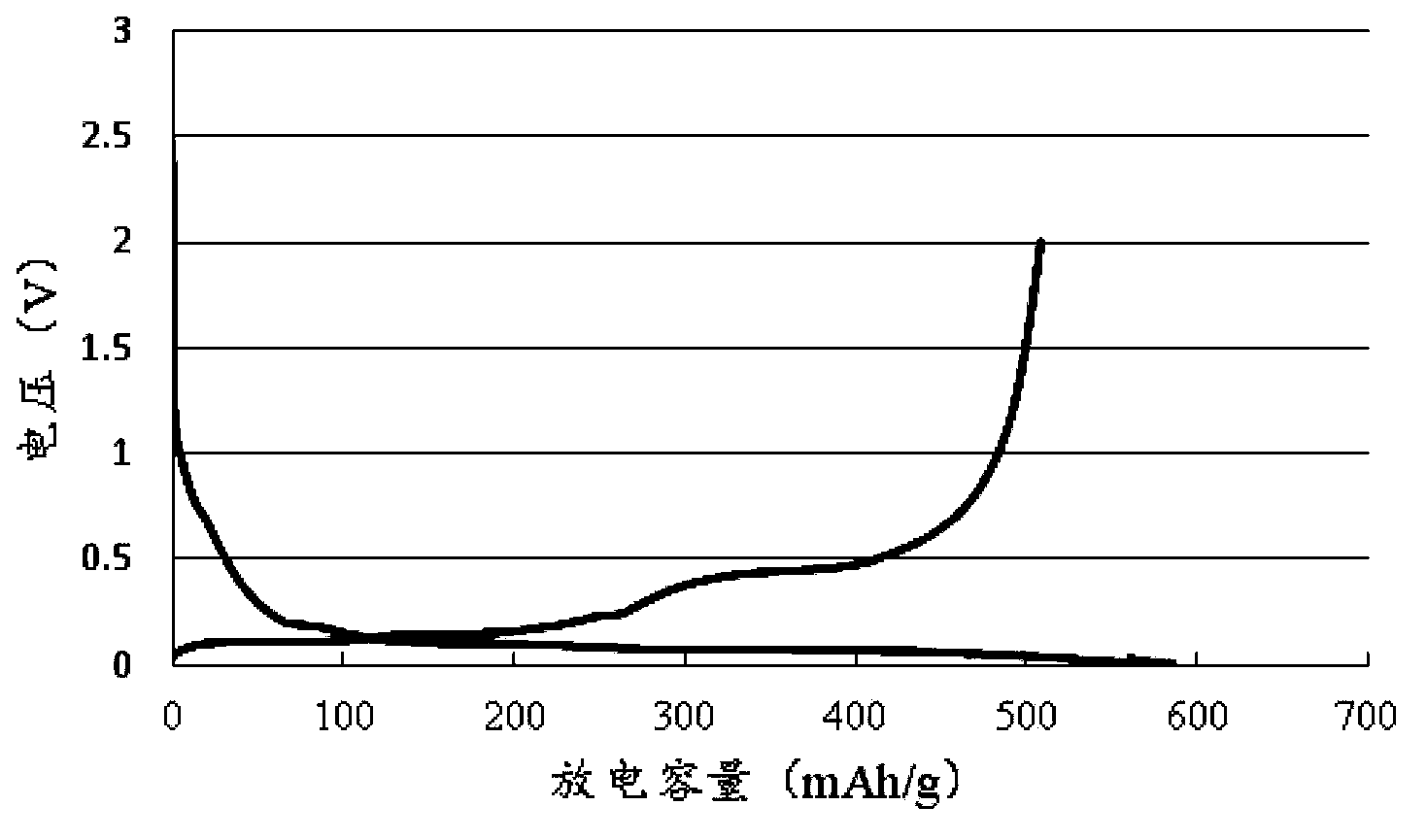

[0087] Application of silicon-silicon oxide-carbon composite materials as anode materials:

[0088] In order to obtain a silicon-based negative electrode material that can be used commercially, on the basis of the silicon-silicon oxide-carbon composite material prepared in Example 3, it was mixed with mesocarbon powder (the model of Shanghai Shanshan Technology Co., Ltd. is MCP) Mesophase carbon powder, commercially available) was fully mixed at a mass ratio of 1:9 for 2 hours. The mixer is a double-helix cantilever cone mixer. The mixed sample is passed through a 150-mesh standard sieve for power supply performance testing.

[0089] The electrochemical performance test method is the same as that of Example 1, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com