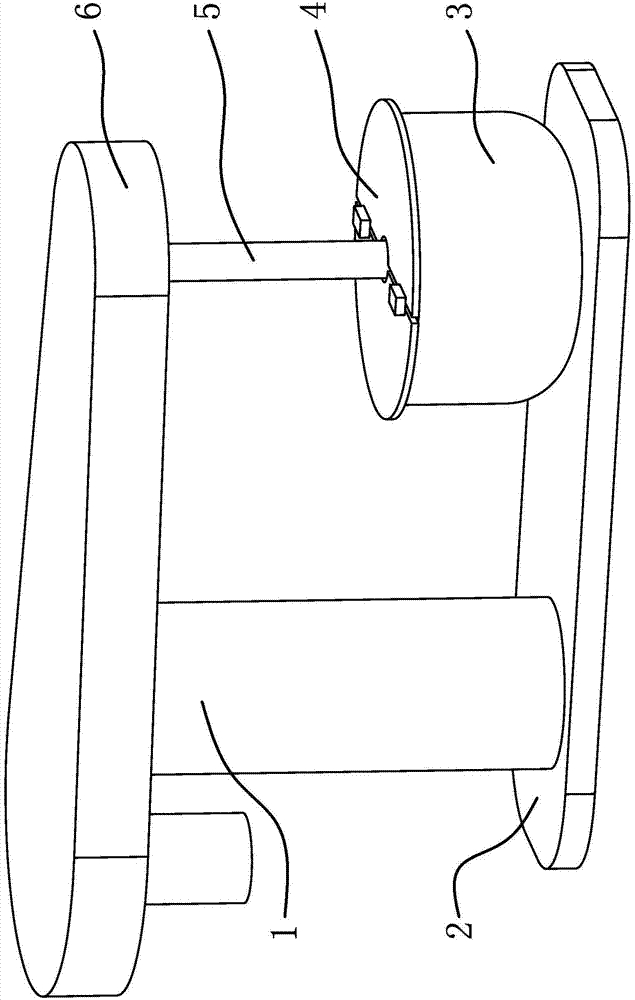

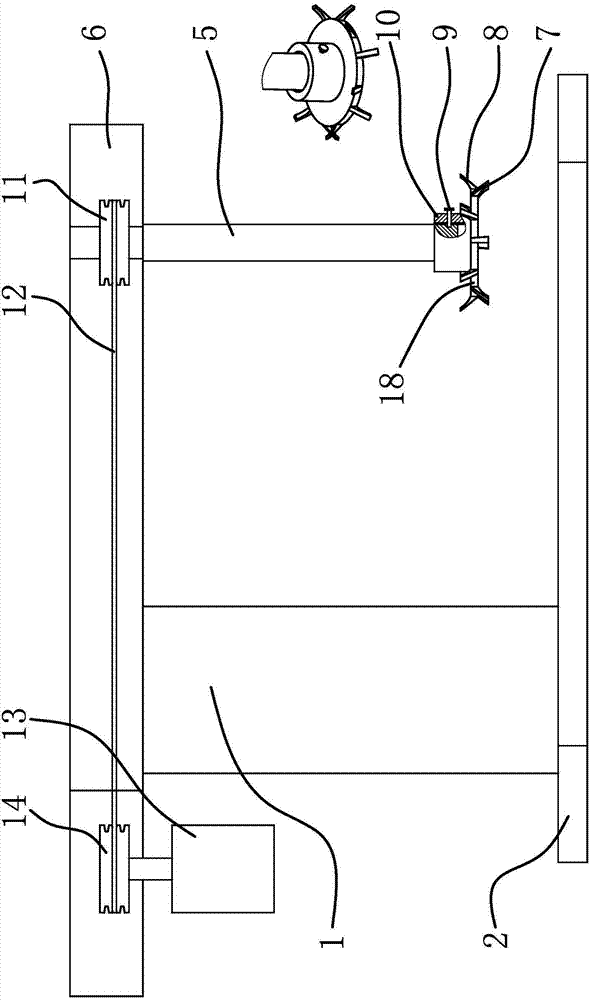

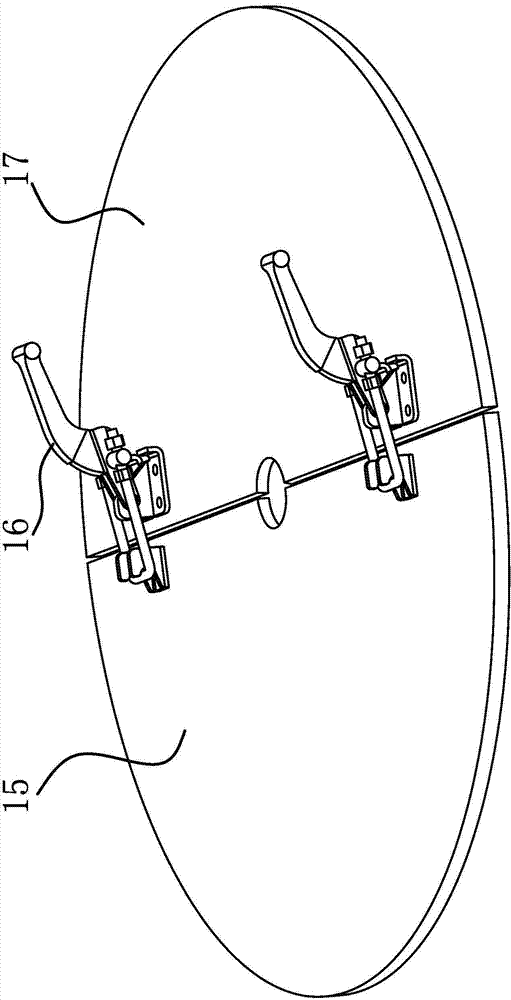

Flame-retardant curtain and production method thereof, and paint disperser for production of flame-retardant curtain

A technology for dispersing machines and curtains, which is applied to window decorations, chemical instruments and methods, mixers with rotating stirring devices, etc. It can solve the problems of affecting personal and property safety, easily damaged plush fabrics, and weak flame retardant effects, etc. problem, to achieve good shear dispersion, good flame retardant effect, and improve the effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] S1. Select a commercially available cotton fabric and cut it into the curtain body, which is divided into the curtain surface layer and the inside of the curtain;

[0037] S2. Weigh the raw materials of the flame retardant layer according to the following volume ratio: 718: 35%, flame retardant: 32%, titanium dioxide: 9%, foam stabilizer: 22%, crosslinking agent: 0.5%, ammonia water: 1.5%; wherein, the flame retardant is a mixture of an organic flame retardant and an inorganic flame retardant at a ratio of 1:1, and the organic flame retardant is a halogenated decabromodiphenylethane, three (2-chloroethyl) Phosphate ester (TCEP), the inorganic flame retardant is aluminum hydroxide, boric acid, and the described foam stabilizer is lauryl dimethyl amine oxide;

[0038] S3. Pour the raw materials of the flame retardant layer, textile latex, flame retardant, titanium dioxide, foam stabilizer, crosslinking agent, and ammonia water into the mixing bucket of the paint disperser...

Embodiment 2

[0041] S1. Select a commercially available cotton fabric and cut it into the curtain body, which is divided into the curtain surface layer and the inside of the curtain;

[0042] S2. Weigh the raw materials of the flame retardant layer according to the following volume ratio: 718: 35%, flame retardant: 35%, titanium dioxide: 10%, foam stabilizer: 18%, crosslinking agent: 0.2%, ammonia water: 1.8%; wherein, the flame retardant is a mixture of an organic flame retardant and an inorganic flame retardant at a ratio of 2:1, and the organic flame retardant is decabromodiphenylethane, tris (2-chloroethyl) phosphate (TCEP), the inorganic flame retardant is magnesium hydroxide, monoammonium phosphate, and the foam stabilizer is an alkanolamide;

[0043] S3. Pour the textile latex, flame retardant, titanium dioxide, foam stabilizer, crosslinking agent, and ammonia water into the mixing tank of the paint dispersing machine in turn, and stir for 30 minutes at a temperature of 30°C until a...

Embodiment 3

[0046] S1. Select a commercially available cotton fabric and cut it into the curtain body, which is divided into the curtain surface layer and the inside of the curtain;

[0047] S2. Weigh the raw materials of the flame retardant layer according to the following volume ratio: 718: 38%, flame retardant: 32%, titanium dioxide: 12%, foam stabilizer: 16%, crosslinking agent: 0.7%, ammonia water: 1.3%; wherein, the flame retardant is a mixture of an organic flame retardant and an inorganic flame retardant at a ratio of 1:1, the organic flame retardant is tris(2-chloroethyl) phosphate (TCEP), and the inorganic Flame retardant is aluminum hydroxide, magnesium hydroxide, and described foam stabilizer is lauryl dimethyl amine oxide;

[0048] S3. Pour the textile latex, flame retardant, titanium dioxide, foam stabilizer, crosslinking agent, and ammonia water into the mixing tank of the paint dispersing machine in turn, and stir for 40 minutes at a temperature of 50°C until a flame retar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com