Preparation method of cerebrolysin vial with high and stable nitrogen content

A technology of cerebroprotein hydrolyzate and nitrogen content, applied to medical preparations containing active ingredients, pharmaceutical formulas, powder delivery, etc., can solve the problems of low nitrogen content and instability of natural cerebroprotein hydrolyzate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

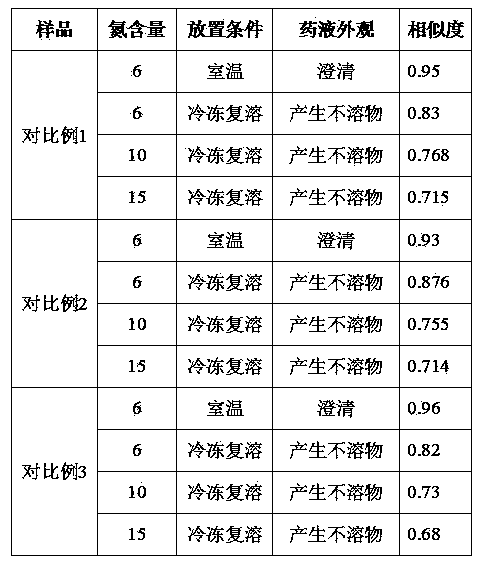

Problems solved by technology

Method used

Image

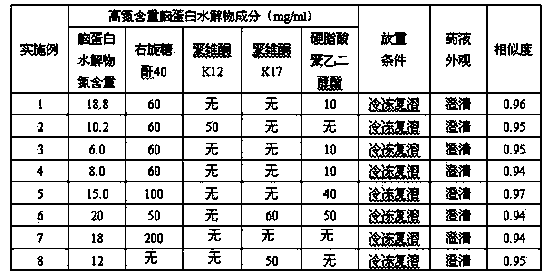

Examples

Embodiment 1

[0019] (1) Take 2 kg of frozen fresh pig brain, soak it in water to thaw naturally, wash it with water, grind it into a slurry, add 8 kg of water 4 times, heat it to 80 ° C, keep it warm for 20 minutes, then cool it to 32 ° C, and then turn it at 3500 rpm Centrifuge for 3 minutes per minute to collect the lower layer of sediment to obtain 1.216 kg of degreased brain pulp;

[0020] (2) Add 3.00 kg of water 1.5 times the mass of fresh pig brain to the degreased brain pulp obtained in step (1) and stir well, then add 20.0 g of pepsin at 1% of the mass of fresh pig brain, and use 50% (w / w ) Dilute hydrochloric acid to adjust the pH value to 3.0, then heat up to 40°C for hydrolysis for 7 hours, adjust the pH value to 8.0 with 50% (w / w) sodium hydroxide solution, and then filter through a 300-mesh nylon sieve to obtain enzymatic hydrolysis liquid;

[0021] (3) Heat the enzymolysis solution obtained in step (2) to 50°C, adjust the pH value to 8.0, then add 30.0 g of 1.5% trypsin in ...

Embodiment 2

[0024] (1) Take 2kg of fresh pig brain, wash it with water, grind it into a slurry, add 6kg of water with 3 times the mass, heat it to 100°C, keep it warm for 10 minutes, then cool it to 40°C, and then perform centrifugation at 3200 rpm for 5 Minutes, collect the sediment in the lower layer to obtain the degreased brain pulp;

[0025] (2) Add 3 kg of water 1.5 times the mass of fresh pig brain to the degreased brain pulp obtained in step (1) and stir evenly, then add 10 g of pepsin 0.5% of the mass of fresh pig brain, adjust the pH value to 2.0, and then heat up to Perform hydrolysis at 50°C for 8 hours, adjust the pH value to 9.0, and then filter through a 300-mesh nylon sieve to obtain the enzymatic hydrolysis solution;

[0026] (3) Heat the enzymolysis solution obtained in step (2) to 40°C, adjust the pH value to 9.0, then add 100 g of 5% trypsin of fresh pig brain mass to carry out hydrolysis for 3 hours, and then circulate and filter the solution through a ceramic membran...

Embodiment 3

[0029] (1) Take 2kg of fresh pig brain, wash it with water, grind it into a slurry, add 4kg of water twice the mass, heat it to 90°C, keep it warm for 15 minutes, then cool it down to 30°C, and then perform centrifugation at 3700 rpm for 1 Minutes, collect the sediment in the lower layer to obtain the degreased brain pulp;

[0030] (2) Add water 1.5 times the mass of fresh pig brain to the degreased brain pulp obtained in step (1), stir well, then add 3% pepsin of fresh pig brain mass, adjust the pH value to 5.0, and then heat up to 50°C Perform hydrolysis for 5 hours, adjust the pH value to 7.0, and then filter through a 300-mesh nylon sieve to obtain the enzymatic solution;

[0031] (3) Heat the enzymolysis solution obtained in step (2) to 60°C, adjust the pH value to 7.0, then add 2.5% fresh pig brain mass trypsin to hydrolyze for 6 hours, and then circulate and filter the solution through a ceramic membrane to clarify the solution. After ultrafiltration by a 10,000 Dalton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com