Oxidation absorption method for converting high-concentration dinitrogen tetroxide waste gas into potassium fertilizer

A technology of dinitrogen tetroxide and oxidation absorption, applied in chemical instruments and methods, potash fertilizers, separation methods, etc., to achieve significant environmental benefits, create economic benefits, and offset treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

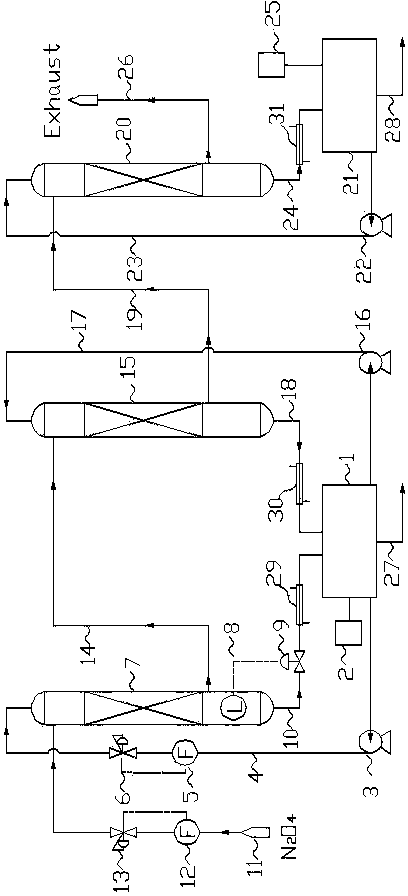

[0028] Such as figure 1 Shown: a device for the harmless treatment of high-concentration dinitrogen tetroxide waste gas, including a primary absorption tower 7, a secondary absorption tower 15, and a tertiary absorption tower 20; the tops of the absorption towers are connected with intake pipes and the absorption liquid inlet pipe; that is, the top of the primary absorption tower 7 is provided with a primary air inlet pipeline and a primary absorption liquid inlet pipe 4, and the top of the secondary absorption tower 15 is provided with a primary tail gas pipe 14 and a secondary absorption liquid inlet pipe 17. The top of the third-stage absorption tower 20 is provided with a second-stage tail gas pipe 19 connected to the second-stage absorption tower and a third-stage absorption liquid inlet pipe 23; 2 o 4 The exhaust gas source 11 is connected, the intake pipeline 14 of the secondary absorption tower is connected with the primary absorption tower 7, the intake pipeline 19 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com