Carbon monoxide releasing material based on natural clay and its preparation method

A carbon monoxide and natural clay technology, applied in chemical instruments and methods, medical preparations with inactive ingredients, pharmaceutical formulas, etc., can solve problems such as heavy metal residues, and achieve the effects of safe and slow-acting release, reduction of residues, and simple preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 0.0585g RuCl 3 Add 20mL ethylene glycol monomethyl ether into the three-necked flask, RuCl 3 The molar ratio to ethylene glycol monomethyl ether is 1:900, pass N 2 After removing the air, CO gas was introduced at a speed of 2 bubbles / second, and the oil bath was heated to 80 °C under stirring conditions, and the reaction was refluxed for 35 minutes. Soil, the amount of sodium montmorillonite added is RuCl 3 20 times the mass of the solution, and the reaction was continued at 80°C for 30 minutes. The color of the solution turned into egg yellow, and the heating was stopped, cooled to room temperature, and spin-dried on a rotary evaporator to obtain 1.1201g of a light gray-green carbon monoxide releasing material based on natural clay. Sealed and stored at low temperature.

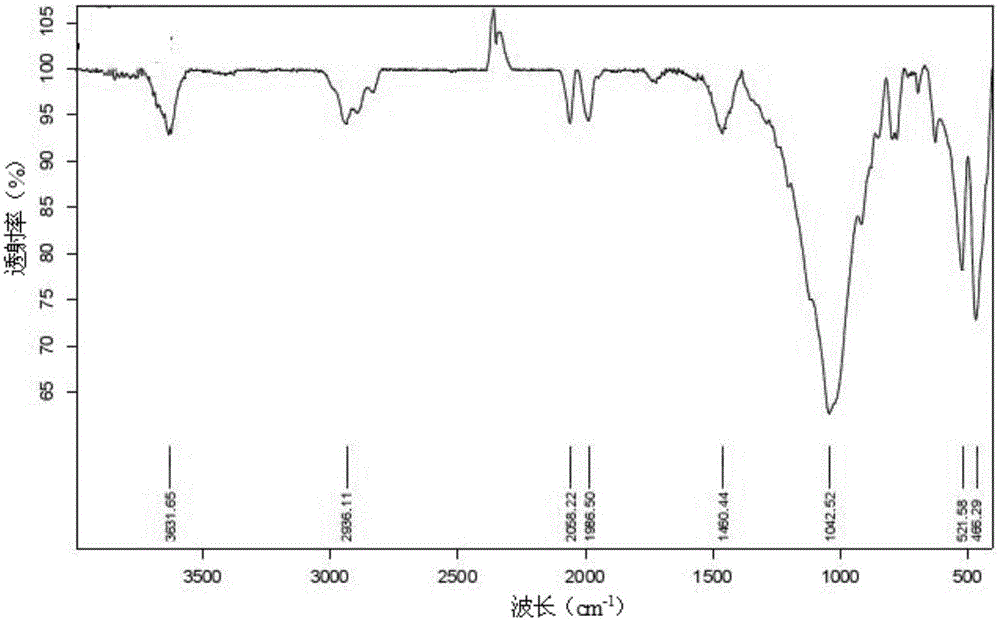

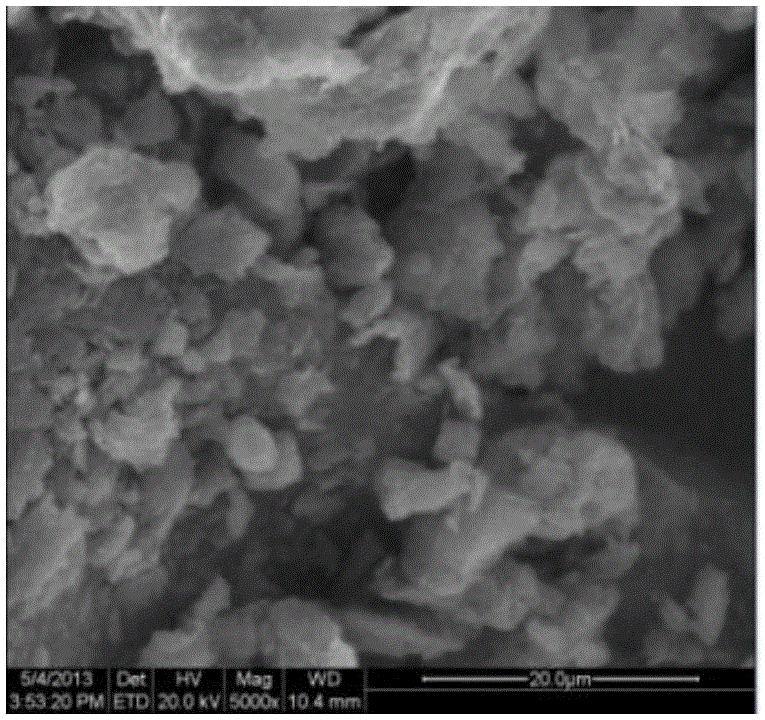

[0021] The prepared carbon monoxide releasing materials based on natural clay were characterized by infrared spectroscopy and environmental scanning electron microscopy, respectively, and the resul...

Embodiment 2

[0025] 0.0481g RuCl 3 Add 20mL ethylene glycol ether into a three-necked flask, RuCl 3 The molar ratio to ethylene glycol ether is 1:900, pass N 2 After removing the air, CO gas was introduced at a rate of 2 bubbles / second, and the oil bath was heated to 80 °C under stirring conditions, and the reaction was refluxed for 35 minutes. The solution turned from brown to blood red. The amount of sodium montmorillonite added is RuCl 3 20 times the mass, then heated to 135°C, refluxed for 30 minutes, the solution turned egg yellow, stopped heating, cooled to room temperature, and spin-dried on a rotary evaporator to obtain a light gray-green carbon monoxide releasing material based on natural clay 1.0247 g, sealed and stored at low temperature.

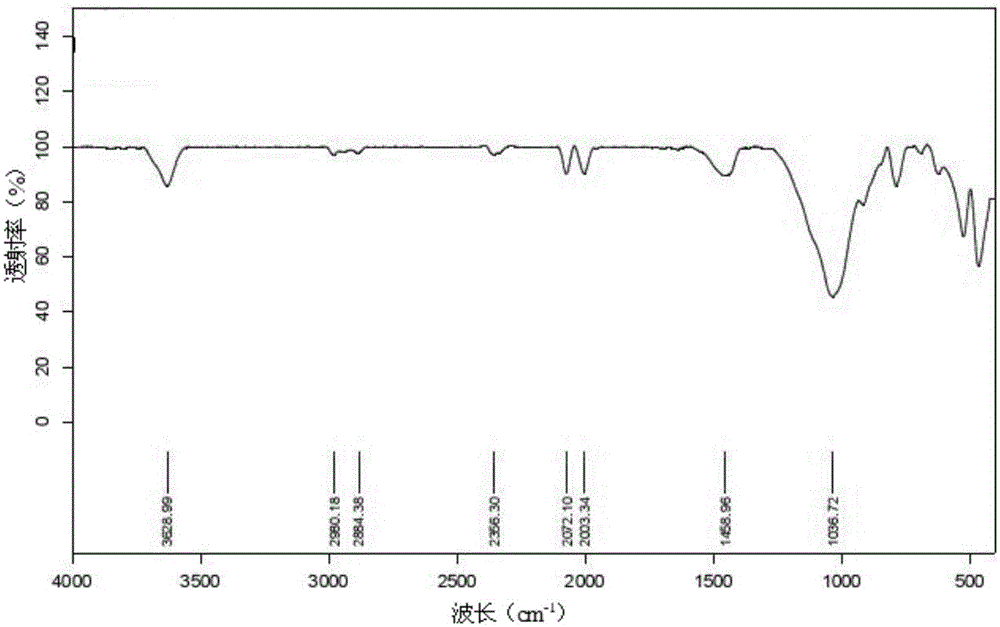

[0026] The prepared carbon monoxide releasing materials based on natural clay were characterized by infrared spectroscopy and environmental scanning electron microscopy, respectively, and the results are shown in Figures 3 to 4 and Table...

Embodiment 3

[0028] 0.0325g RuCl 3 Add 20mL ethylene glycol monomethyl ether into the three-necked flask, RuCl 3 The molar ratio with ethylene glycol monomethyl ether is 1:500, pass N 2 After removing the air, CO gas was introduced at a speed of 2 bubbles / second, and the oil bath was heated to 70 °C under stirring conditions, and the reaction was refluxed for 60 minutes. Soil, the amount of calcium montmorillonite added is RuCl 315 times the mass of the solution, continue to reflux at 70°C for 60 minutes, the color of the solution turns egg yellow, stop heating, cool to room temperature, spin dry on a rotary evaporator to obtain a light gray-green carbon monoxide release material based on natural clay, sealed at low temperature save.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com