Three-stage pressure-reducing V-shaped hydraulic cyclone air floatation device

A hydrocyclone and air flotation technology, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of low power consumption, influence of purification efficiency, and reduction of purification efficiency, etc. , to achieve the effect of saving space, compact structure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

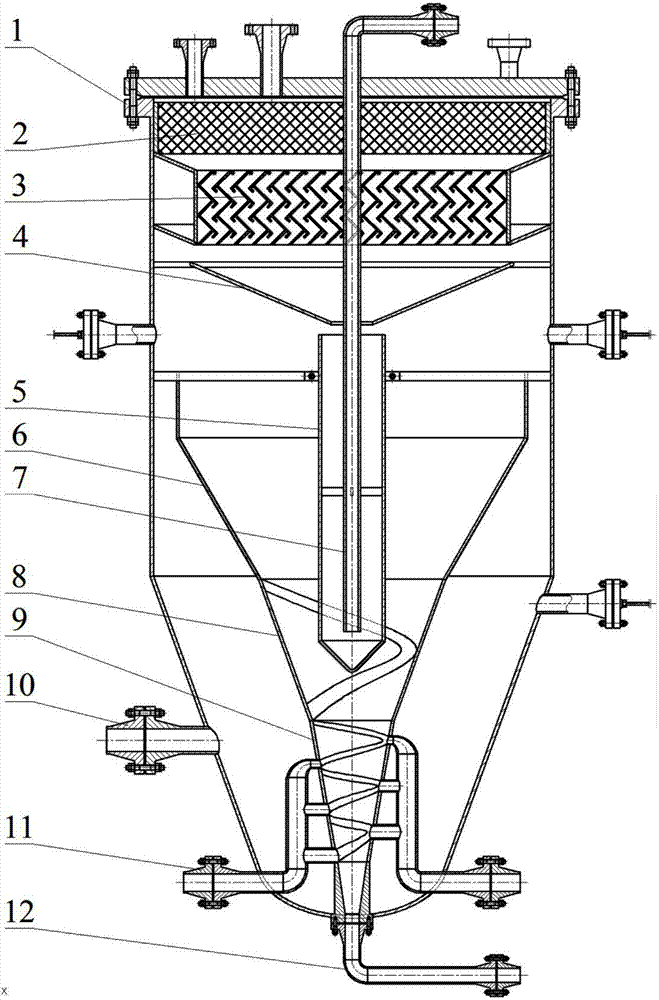

[0032] exist figure 1 Among them, the three-stage step-down V-shaped hydrocyclone air flotation device consists of an air flotation tank 1, a wire mesh filter 2, a gas rectifier 3, a liquid collector 4, a first-stage cyclone 9, and a second-stage cyclone 8 , The third stage cyclone 6, the oil collecting pipe 5, the oil outlet pipe 7, the water outlet pipe 10, the liquid inlet pipe 11 and the sewage pipe 12 are composed. When assembling, first connect the first-stage cyclone 9, the second-stage cyclone 8 and the third-stage cyclone 6 to the tank body of the air flotation tank 1 in order to ensure that the outlet of the liquid inlet pipe 11 enters the first stage tangentially. The cone swirl section of the first-stage cyclone 9, and then the oil collecting pipe 5 is connected to the reinforcement of the third-stage cyclone, and then the liquid collector 4, the gas rectifier 3 and the wire mesh liquid filter 2 are sequentially installed into the air flotation Inside the tank 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com