Method for promoting anaerobic digestion of sludge through microbial electrical mediation

An anaerobic digestion and electrical mediated technology, applied in biological sludge treatment, chemical instruments and methods, sludge treatment, etc. Sludge organic matter utilization rate is low and methane recovery rate is low, which can achieve the effect of sludge treatment effect and energy gain promotion, promoting sludge anaerobic digestion, and improving VSS removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

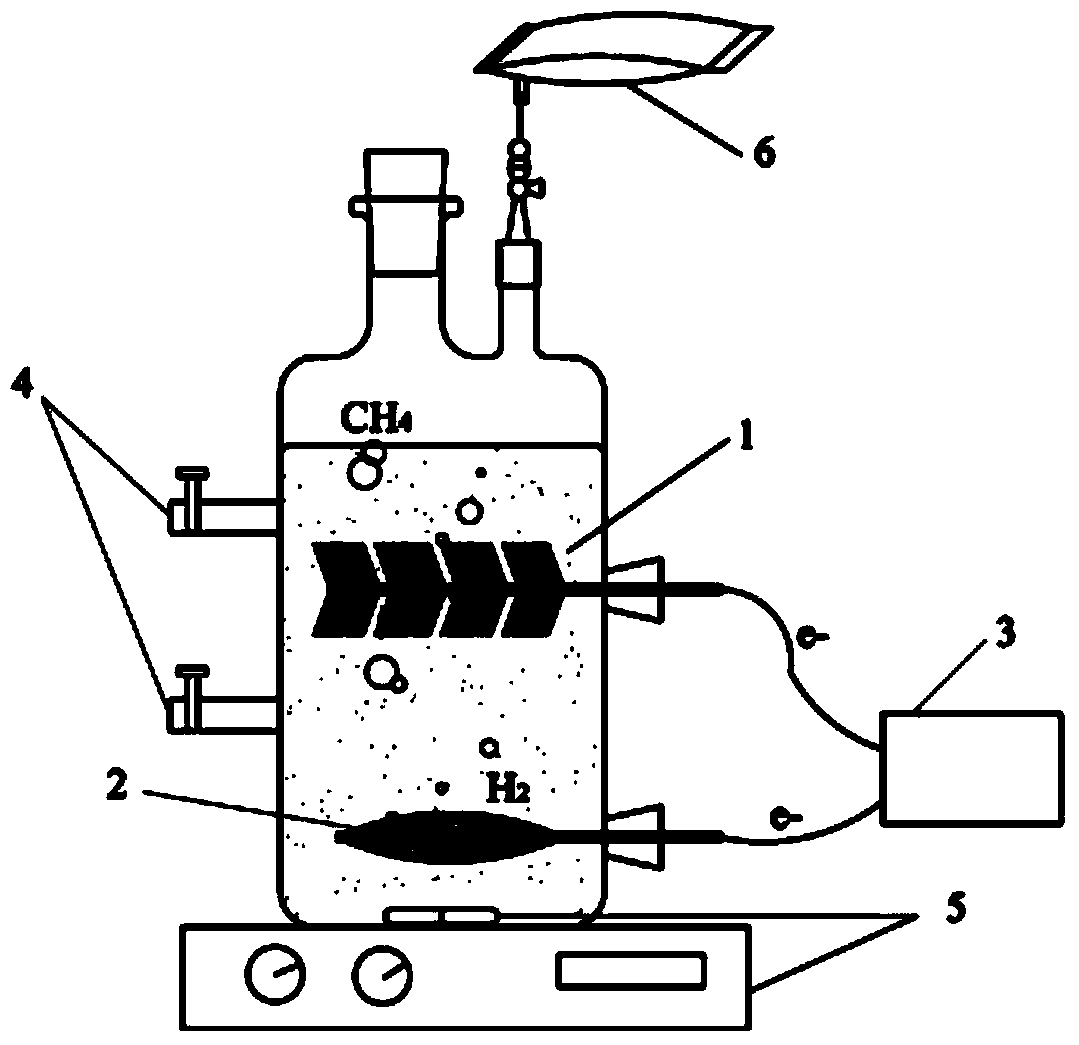

[0020] Specific embodiment 1: The method for promoting the anaerobic digestion of sludge by microbial electrical mediation in this embodiment is carried out according to the following steps:

[0021] 1. Sludge pretreatment: adjust the sludge concentration to 14000mg / L, use dual-frequency ultrasound to pretreat the sludge for 10 minutes, adjust the pH value of the sludge to 10 with sodium hydroxide solution, and then refrigerate for use;

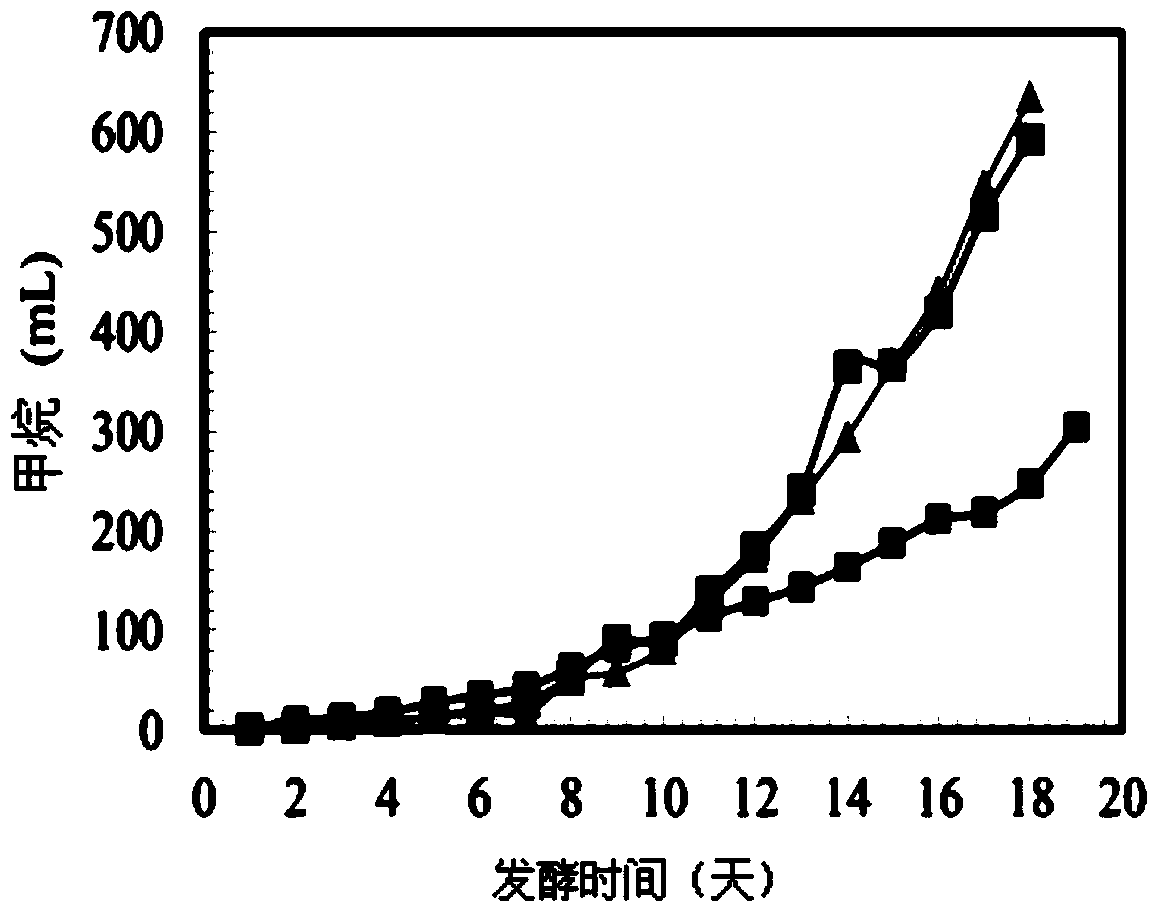

[0022] 2. Microbiological acclimatization of anode electrolytic flora function: the single-chamber MEC reactor is used as the anaerobic acclimation device for microbial electrolysis, and a fixed microvoltage of 0.6-0.9V is added to both ends of the electrode, cultivated at 30°C, and the single-chamber MEC reactor is started. , 24h is a cycle, and the medium is replaced every 24h. After the medium is changed in the single-chamber MEC reactor, nitrogen with a purity of 99.998% is continuously introduced into the reaction chamber for 20min to rem...

specific Embodiment approach 2

[0025] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the dual-frequency ultrasonic treatment of the sludge in step 1 is carried out in a trough ultrasonic instrument equipped with ultrasonic generators with frequencies of 28kHz and 40kHz , The sound energy density of ultrasonic pretreatment is 0.25 ~ 1.0kW / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that in step 2, an additional 0.8V microvoltage is added to both ends of the electrodes. Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com