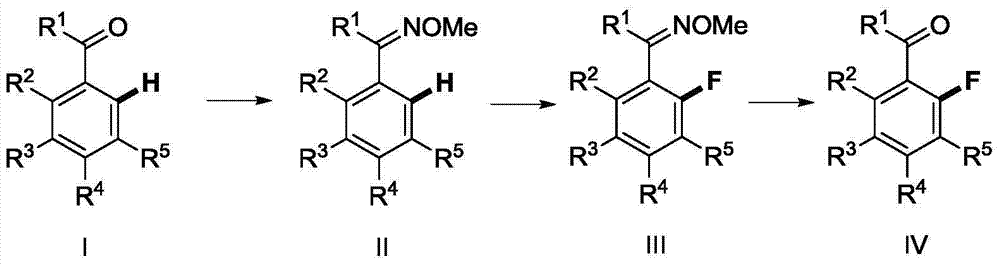

Method for synthesizing 2-fluoroarylcarbonyl compounds

A technology for aryl carbonyl compounds, which is applied in the field of synthesizing 2-fluoroaryl carbonyl compounds, can solve the problems of poor fluorination selectivity, complex directing groups, narrow substrate range, etc., and achieve mild reaction conditions and fluorination selectivity High performance and good substrate adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

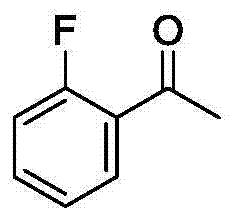

Embodiment 1

[0049]

[0050] [1] Add 0.600g (5.0mmol) of acetophenone, 0.835g (10.0mmol) of methoxylamine hydrochloride, 1.640g (20.0mmol) of anhydrous sodium acetate, 10ml of ethanol and 30ml of water into a 100ml flask. After the mixture was heated to reflux for 2 hours, TLC detected that the reaction was complete, and 30 ml of ethyl acetate was added for dilution and extraction. The organic phase was dried and the solvent was removed under reduced pressure to obtain 0.708 g of acetophenone oxime ether (95% yield).

[0051] [2] Add acetophenone oxime ether (44.7mg, 0.3mmol), tris(dibenzylideneacetone) dipalladium (13.7mg, 0.015mmol), N-fluorobenzenesulfonyl Amine (189.0mg, 0.6mmol), potassium nitrate (9.1mg, 0.09mmol), nitromethane (3.0mL), the reaction mixture was stirred at 25°C, followed by TLC detection, and the reaction was complete within 24 hours. Stop the reaction, dilute the mixture with dichloromethane, filter and remove the solvent under reduced pressure, and the residue is...

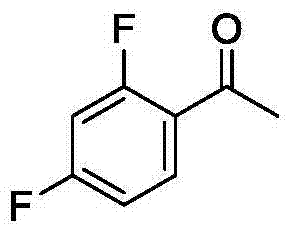

Embodiment 2

[0054]

[0055] [1] Add 0.690g (5.0mmol) of 4-fluoroacetophenone, 0.835g (10.0mmol) of methoxyamine hydrochloride, 1.640g (20.0mmol) of anhydrous sodium acetate, 10ml of ethanol and 30ml of water into a 100ml flask inside. After the mixture was heated to reflux for 2 hours, TLC detected that the reaction was complete, and 30ml of ethyl acetate was added for dilution and extraction. The organic phase was dried and the solvent was removed under reduced pressure to obtain 0.776g of 4-fluoroacetophenone oxime ether (93% yield). .

[0056] [2] Add 4-fluoroacetophenone oxime ether (50.1mg, 0.3mmol), tris(dibenzylideneacetone) dipalladium (13.7mg, 0.015mmol), N-fluorobenzene Sulfonimide (189.0mg, 0.6mmol), potassium nitrate (9.1mg, 0.09mmol), nitromethane (3.0mL), the reaction mixture was stirred at 40°C, followed by TLC detection, and the reaction was complete within 24 hours. Stop the reaction, dilute the mixture with dichloromethane, remove the solvent under reduced pressure ...

Embodiment 3

[0059]

[0060] [1] Add 0.750g (5.0mmol) of 4-methoxyacetophenone, 0.835g (10.0mmol) of methoxyamine hydrochloride, 1.640g (20.0mmol) of anhydrous sodium acetate, 10ml of ethanol and 30ml of water 100ml flask. After the mixture was heated to reflux for 2 hours, TLC detected that the reaction was complete, and 15 ml of ethyl acetate was added for dilution and extraction. The organic phase was dried and the solvent was removed under reduced pressure to obtain 0.841 g of 4-methoxyacetophenone oxime ether (94% yield). Rate).

[0061] [2] Add 4-methoxyacetophenone oxime ether (53.7mg, 0.3mmol), tris(dibenzylideneacetone) dipalladium (13.7mg, 0.015mmol), N-fluoro Phenylenesulfonylimide (189.0mg, 0.6mmol), potassium nitrate (9.1mg, 0.09mmol), nitromethane (3.0mL), the reaction mixture was stirred at 25°C, followed by TLC detection, and the reaction was complete within 24 hours. Stop the reaction, dilute the mixture with dichloromethane, remove the solvent under reduced pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com