A kind of method for preparing xylene formaldehyde resin

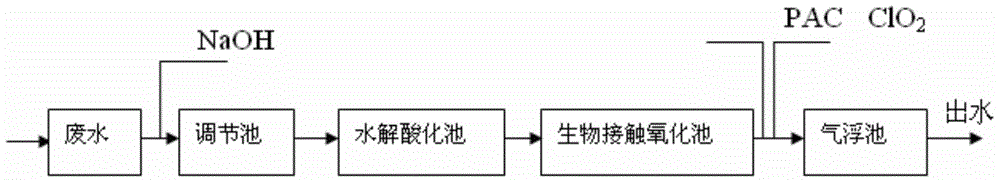

A xylene formaldehyde resin and xylene technology, applied in the polymer field, can solve the problems of difficult waste liquid treatment, opaque products, low resin yield, etc., and achieve the effects of high environmental protection value, easy handling, and improved quality and yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

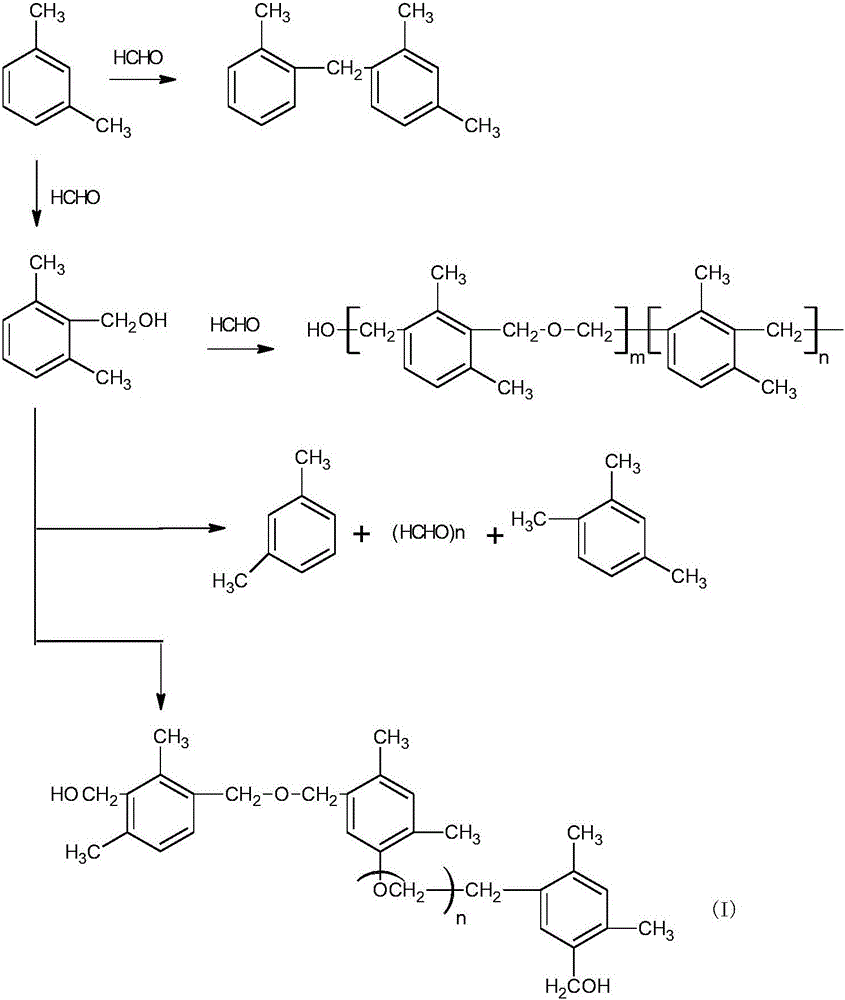

Method used

Image

Examples

Embodiment 1

[0057] In the enamel reactor with stirring of 5000L, add 1000kg mass concentration and be the formaldehyde of 37% and the xylene of 1400kg, under the cooling of jacket cooling water, slowly add 432kg mass concentration therein in 45 minutes and be 98% sulfuric acid, After the addition, slowly heat up to boiling reflux within 30 minutes, and react at constant temperature for 6 hours;

[0058] After the constant temperature reaction, the reaction liquid is stilled, and the sulfuric acid is separated, and 1440 kg of ion-free water is added to the remaining xylene formaldehyde resin, neutralized with triethanolamine, and when the pH value is 6.5 to 7.5, 7.2 kg of demulsifier is added to it and stirred evenly , stand still, separate water and xylene formaldehyde resin solution;

[0059] Put the xylene formaldehyde resin solution into the debenzene kettle, and under the condition of 130°C, decompress to remove the unreacted xylene. When the viscosity of the resin reaches 150cp / 25°C,...

Embodiment 2

[0064] In the enamel reactor of 5000L band agitation, add 420kg paraformaldehyde and 1400kg xylene, under the cooling of jacket cooling water, slowly add 455kg mass concentration wherein to it in 60 minutes and be the sulfuric acid of 98%, after adding, in Slowly heat up to boiling reflux within 45 minutes, and react at a constant temperature for 7 hours;

[0065] After the constant temperature reaction, the reaction liquid is stilled, and the sulfuric acid is separated, and 1440 kg of deionized water is added to the remaining xylene formaldehyde resin, neutralized with triethanolamine, and when the pH value is 6.5 to 7.5, 3.64 kg of demulsifier is added to it and stirred evenly , stand still, separate water and xylene formaldehyde resin solution;

[0066] Pour the xylene formaldehyde resin solution into the debenzene kettle, and under the condition of 150°C, decompress and remove the unreacted xylene. When the viscosity of the resin reaches 300cp / 25°C, it is the end point of ...

Embodiment 3

[0071] In a 5000L enamel reactor with stirring, add 568kg of formaldehyde with a mass concentration of 37% and 1400kg of xylene, under the cooling of jacket cooling water, slowly add 393.6kg of sulfuric acid with a mass concentration of 98% within 50 minutes, add After that, slowly heat up to boiling reflux within 40 minutes, and react at constant temperature for 8 hours;

[0072] After the constant temperature reaction, the reaction liquid is stilled, and the sulfuric acid is separated, and 1440 kg of deionized water is added to the remaining xylene formaldehyde resin, neutralized with triethanolamine, and when the pH value is 6.5 to 7.5, 9.84 kg of demulsifier is added to it, and stirred evenly , stand still, separate water and xylene formaldehyde resin solution;

[0073] Pour the xylene formaldehyde resin solution into the debenzene kettle, and under the condition of 150°C, decompress and remove the unreacted xylene. When the viscosity of the resin reaches 300cp / 25°C, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com