Halogen-free polyolefin composition and product thereof

A composition and polyolefin technology, applied in the field of halogen-free polyolefin composition, can solve the problems of unsatisfactory surface resistance value, not seen in, unsuitable for coal mine application, etc., achieve excellent flame retardancy and antistatic property, good mechanical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] Preparation of compositions and articles

[0060] The thermoplastic resins according to the present invention can be prepared by conventional methods known in the art. In an exemplary embodiment, the above components (a), (b) and (c) are mixed with optional thermoplastic elastomer (d), compatibilizer (e), filler (f) and additive (g) The resulting polyolefin composition can then be prepared in the form of pellets (eg pellets) by melt extrusion in a twin-screw extruder, if necessary using a die.

[0061] The thermoplastic resin composition pellets of the present invention can be subjected to injection molding or the like to obtain desired products.

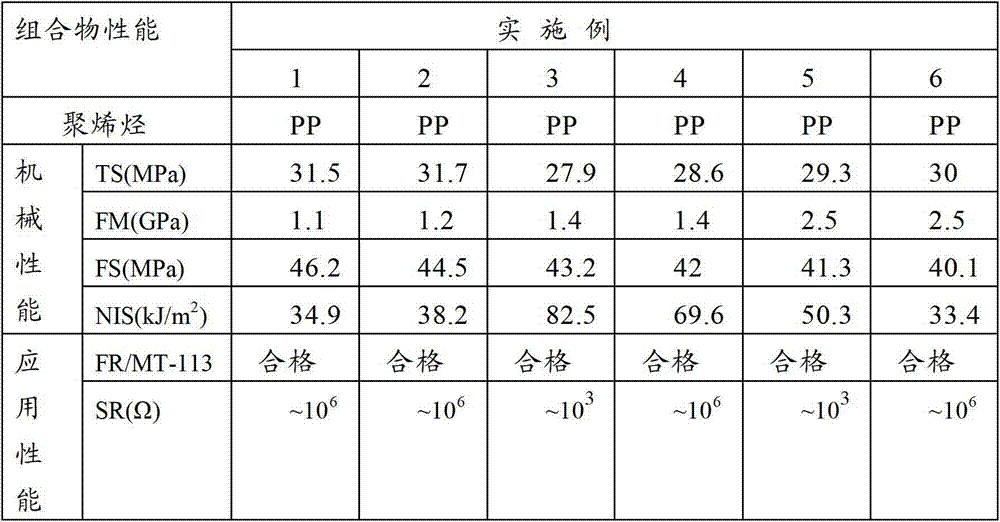

[0062] The halogen-free polyolefin composition of the present invention has excellent flame retardancy and antistatic properties, all of which meet or even exceed the requirements stipulated in MT113-1995, specifically including (i) flame retardancy, flame burning duration8 Ω; and wherein the mechanical strength of the compo...

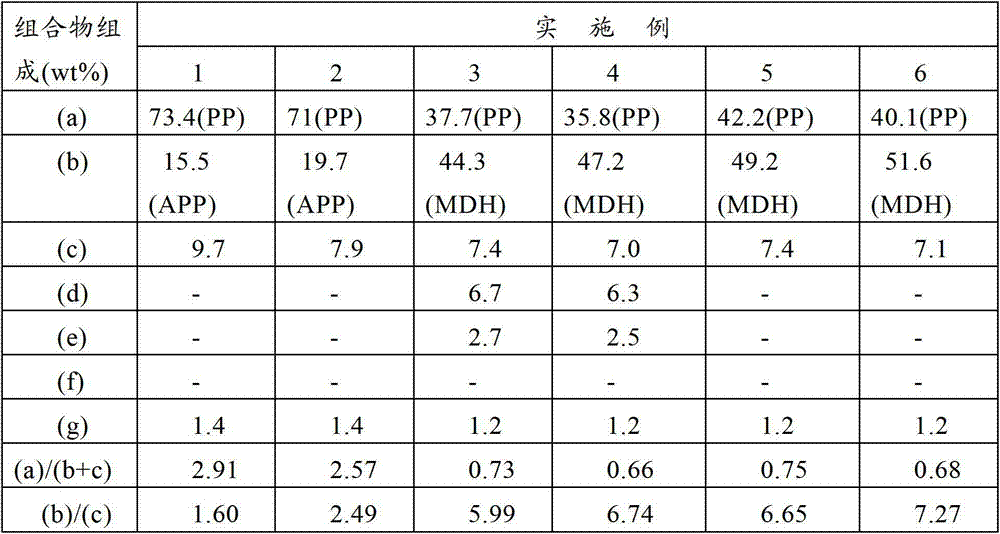

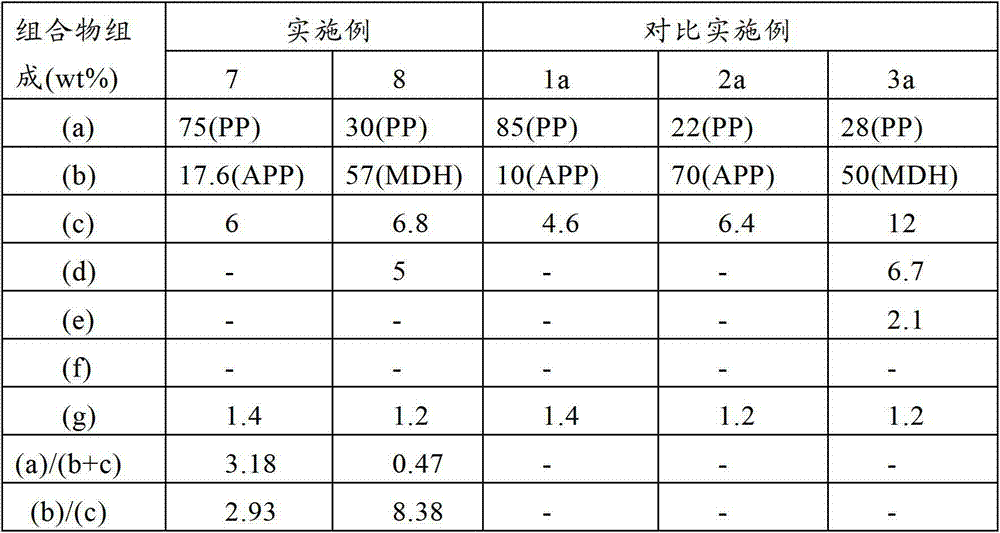

Embodiment 1

[0074] 73.4 parts by weight of (a) polypropylene homopolymer (MFR=3.5g / 10min, weight average molecular weight approximately equal to 400,000, the same below), 15.5 parts by weight of (b) ammonium polyphosphate (molecular weight of 225,000, the same below) , (c) conductive carbon black (specific surface area 662m 2 / g, the same below) and a total of 1.4 parts by weight containing stearic acid (processing aid, 0.5 parts by weight), 2,6-tert-butyl-4-methylphenol (heat stabilizer, 0.3 parts by weight), poly Mixture of additives of vinyl wax (release agent, molecular weight 6,000, 0.5 parts by weight) and 2,2'-methylenebis(4-methyl-6-tert-butylphenol) (antioxidant, 0.1 parts by weight) Use a twin-screw extruder with a diameter of 36 mm (SHJ-36, Nanjing Jieente Electromechanical Co., Ltd., the same below) to melt and knead at 80 ° C for 30 minutes and pelletize. Then according to the aforementioned standard sample preparation, testing mechanical properties, flame retardancy and anti...

Embodiment 2

[0076] 71 parts by weight of polypropylene homopolymer (MFR=3.5g / 10min, weight average molecular weight equal to about 400,000), 19.7 parts by weight of ammonium polyphosphate (molecular weight of 225,000), 7.9 parts by weight of conductive carbon black and a total of 1.4 Parts by weight contain stearic acid (processing aid, 0.5 parts by weight), 2,6-tert-butyl-4-methylphenol (heat stabilizer, 0.3 parts by weight), polyethylene wax (release agent, molecular weight is 6,000,0.5 parts by weight) and 2,2'-methylene bis(4-methyl-6-tert-butylphenol) (antioxidant, 0.1 parts by weight) of the additive mixture with a diameter of 36mm twin-screw extruder Exit the machine to melt knead and granulate. Then according to the aforementioned standard sample preparation, testing mechanical properties, flame retardancy and antistatic properties, the results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com