Method for preparing kaolinite with high radius-thickness ratio, and measuring and calculating radius-thickness ratio of kaolinite

A technology of kaolinite and diameter-thickness ratio, which is applied in the preparation of test samples, measuring devices, particle size analysis, etc., can solve the problems of high measurement cost, low accuracy, and complicated calculation methods, and achieve good repeatability and accuracy The effect of high precision and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

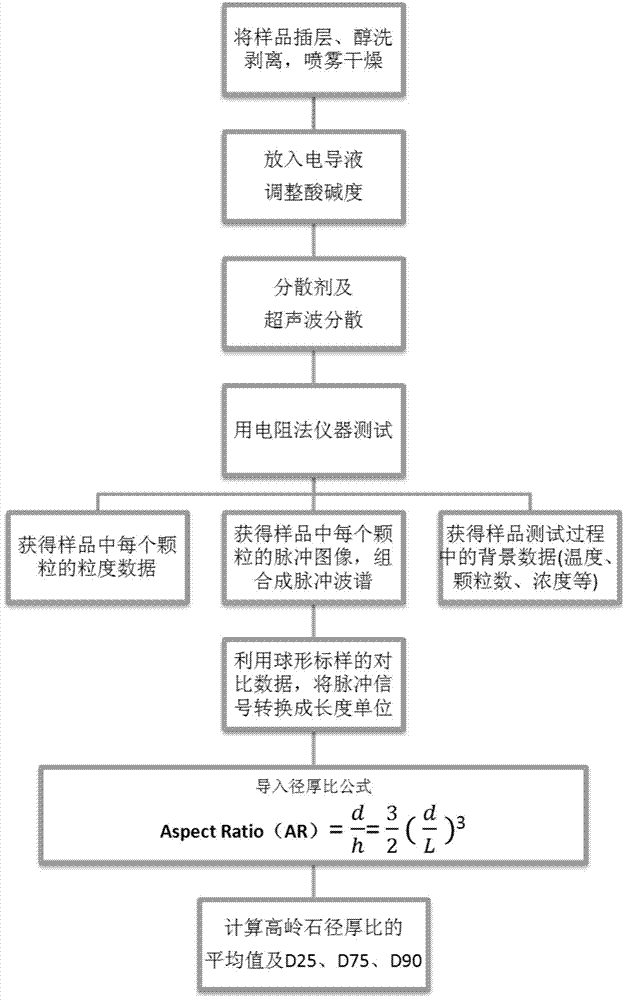

[0054] The preparation of the high-diameter-thickness ratio ridge stone sheet and the calculation method of the diameter-thickness ratio provided in this example are as follows: Figure 4 shown, including:

[0055] Step 1, intercalate the kaolin to be tested with a supersaturated dimethyl sulfoxide solution, wash and filter with methanol, spray dry, put it in a conductive solution, adjust the acidity and alkalinity of the solution, and keep the pH value at 9.5-10, Ultrasonic dispersion is performed after adding a dispersant for dispersion.

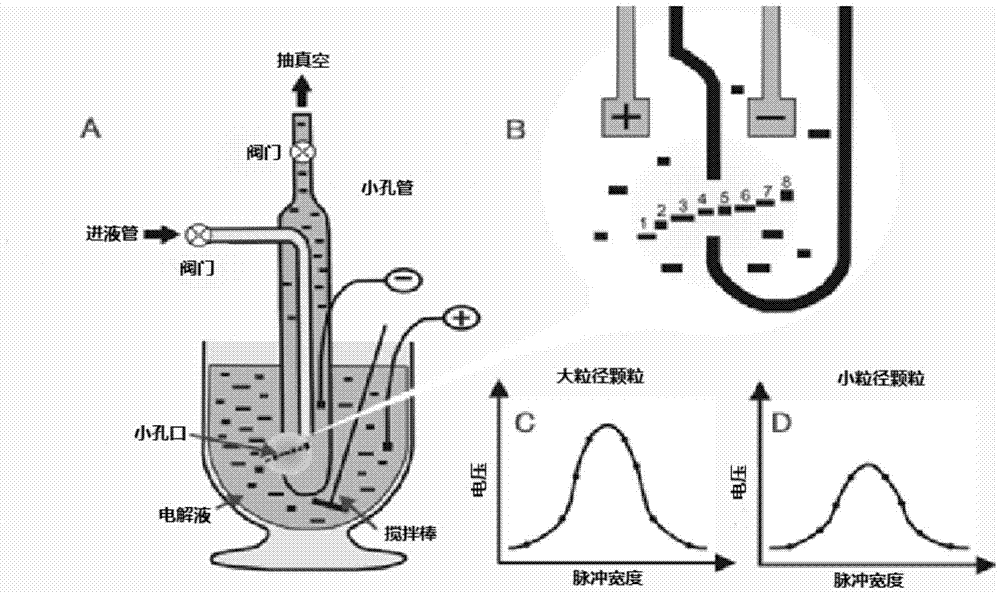

[0056] Step 2, using the Multisizer3 Beckman Coulter instrument, place the microporous tube in the suspension of the test instrument, place electrodes inside and outside the microporous tube to energize, and measure the tiny resistance changes produced by the sample particles one by one; through the amplifier, the tiny The voltage is transformed into a voltage pulse signal that can be accurately measured;

[0057] Step 3, using the compa...

Embodiment

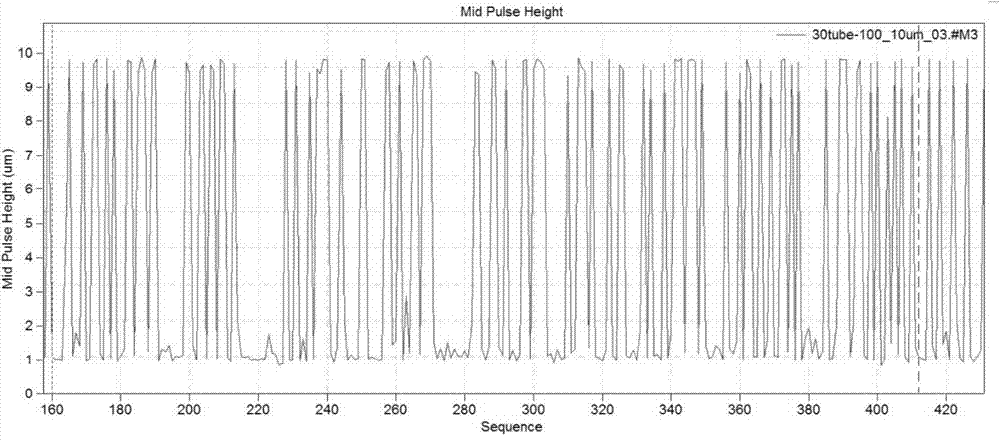

[0061] Taking the kaolin sample in Xuanhua area as an example, through the above implementation method, the average pulse height of the sample can be measured as L=1.7944 μm, and the average pulse width is W=9.11 μs. Compared with the standard spherical particle pulse data and particle size comparison table 1, W is between 8.57 and 9.29, then corresponding, n=4, W n =8.57μs, W n+1 =9.29μs, then substitute into the formula: d W = n + W - W n W n + 1 - W n = 4 + W - W 4 W ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap