Heterogeneous double-face fluorine-containing solar battery backboard

A solar cell, double-sided technology, applied in the direction of circuits, electrical components, lamination devices, etc., can solve the problems of high cost, instability, poor weather resistance, etc., to improve the effective service life, slow down the aging speed, and improve the adhesion The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

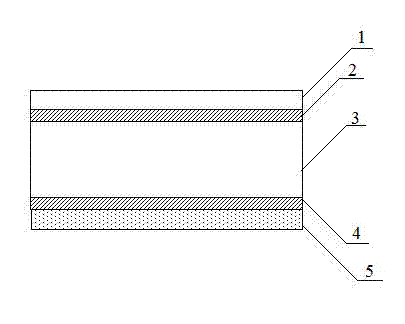

[0024] Such as figure 1 A heterogeneous double-sided fluorine-containing solar cell back sheet is shown, the back sheet includes a fluorine film layer 1, an adhesive layer 2, a film layer 3, a primer layer 4 and a coating layer 5 connected in sequence, wherein the fluorine The film layer is polyvinylidene fluoride film or polyvinyl fluoride film, the thickness of the fluorine film layer is 20-30 microns, the adhesive layer is polyurethane two-component adhesive, the thickness of the adhesive layer is 5-30 microns, The film layer is a polyethylene terephthalate film, the thickness of the film layer is 100-400 microns, the base coat is a polyurethane-like adhesive, the thickness of the base coat is 5-30 microns, and the coating layer is polyester The coating paint is formed by dispersing tiny particles of tetrafluoroethylene or polyvinylidene fluoride and base resin in a sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com