Infrared detector and manufacturing method thereof

An infrared detector and tablet technology, which is applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as low working temperature of detectors, and achieve low manufacturing cost, reasonable structure and good detection effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The concrete steps of preparation are:

[0037] In step 1, vanadium pentoxide, oxalic acid dihydrate and deionized water are mixed according to a weight ratio of 1.8:1:2000, and stirred at 35° C. for 12 hours to obtain a vanadyl oxalate precursor solution. Then the vanadyl oxalate precursor solution was placed in a closed state, and reacted at 200° C. for 6 days to obtain a reaction solution containing precipitates.

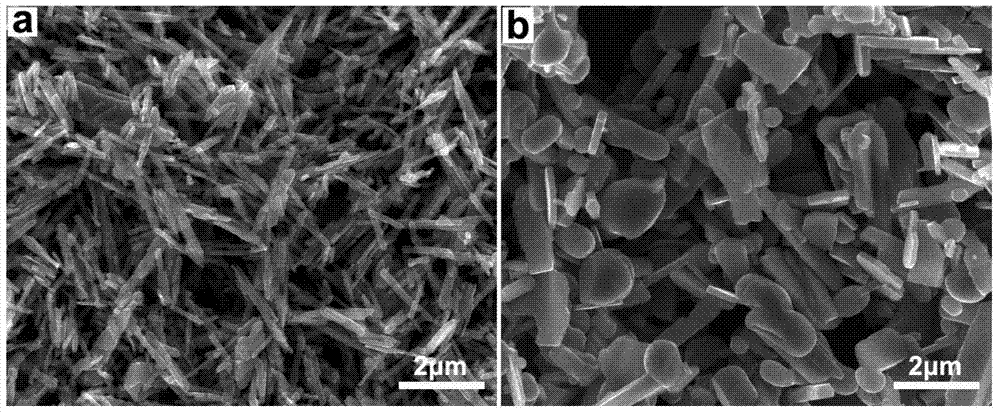

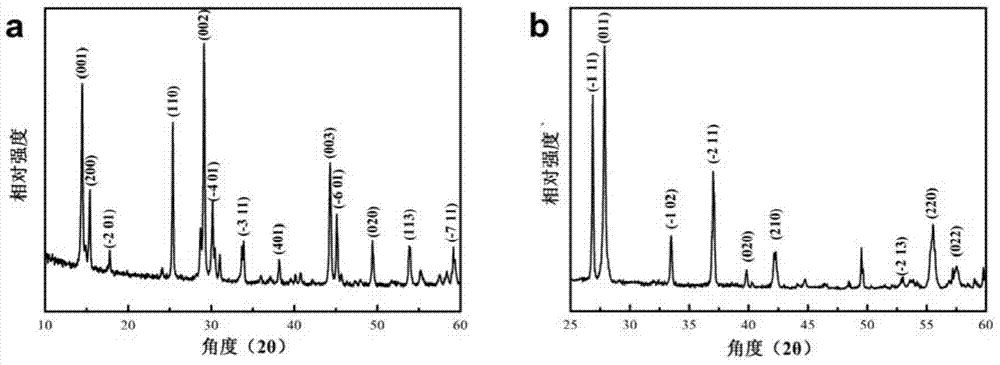

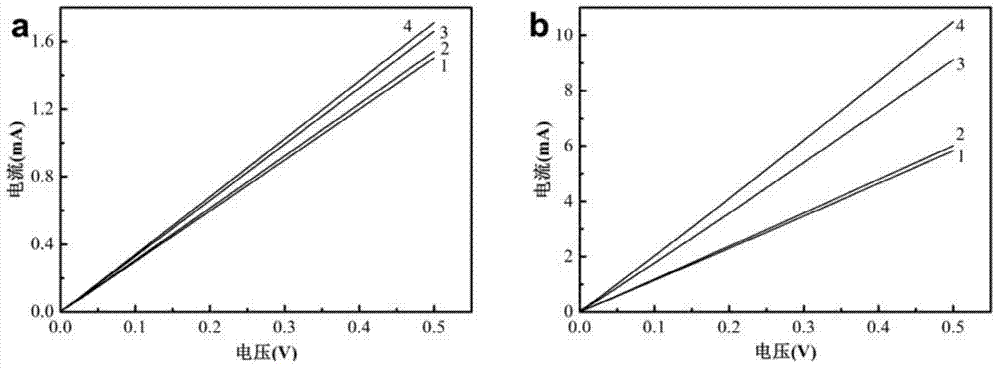

[0038] In step 2, the reaction solution containing the precipitate is first subjected to solid-liquid separation, washing and drying; wherein, the solid-liquid separation treatment is centrifugation, the speed of centrifugation is 6000r / min, and the time is 8min, and the washing treatment is to use the Ionized water and ethanol are used to alternately wash the separated solid matter twice. The separation of the solid matter during cleaning is centrifugation, and the drying process is to dry the cleaned solid matter at 60°C to obtain an approximate figure ...

Embodiment 2

[0041] The concrete steps of preparation are:

[0042] In step 1, vanadium pentoxide, oxalic acid dihydrate and deionized water are mixed according to a weight ratio of 1.9:1:1500, and stirred at 38°C for 10 hours to obtain a vanadyl oxalate precursor solution. Then the vanadyl oxalate precursor solution was placed in a closed state, and reacted at 210° C. for 4.5 days to obtain a reaction solution containing precipitates.

[0043] In step 2, the reaction solution containing the precipitate is first subjected to solid-liquid separation, washing and drying; wherein, the solid-liquid separation treatment is centrifugation, the speed of centrifugation is 7000r / min, and the time is 7min. Ionized water and ethanol are used to alternately wash the separated solid matter three times. The separation of the solid matter during cleaning is centrifugation, and the drying process is to dry the cleaned solid matter at 65 ° C to obtain a similar figure 1 as shown in a, and as figure 2 Ph...

Embodiment 3

[0046] The concrete steps of preparation are:

[0047] In step 1, vanadium pentoxide, oxalic acid dihydrate and deionized water are mixed according to a weight ratio of 2:1:1000, and stirred at 40° C. for 8 hours to obtain a vanadyl oxalate precursor solution. Then, the vanadyl oxalate precursor solution was placed in a closed state, and reacted at 220° C. for 3 days to obtain a reaction solution containing precipitates.

[0048] In step 2, the reaction solution containing the precipitate is first subjected to solid-liquid separation, washing and drying; wherein, the solid-liquid separation treatment is centrifugation, the speed of centrifugation is 8000r / min, and the time is 6min, and the washing treatment is to use the Ionized water and ethanol are used to alternately wash the separated solid matter twice. During washing, the solid matter is separated by centrifugation, and the drying process is to dry the cleaned solid matter at 70°C to obtain the following: figure 1 as sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com