Lithium-enriched manganese-based anode material with fast ion conductor coating layer and surface heterostructure and preparation method of lithium-enriched manganese-based anode material

A lithium-rich manganese-based, positive electrode material technology, applied in the direction of structural parts, battery electrodes, electrical components, etc., can solve the problems of difficult industrial production of the preparation process, and achieve the convenience of large-scale industrial production, low manufacturing cost, and reproducibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Put 5g of lithium-rich manganese-based cathode material Li 1.2 Ni 0.13 co 0.13 mn 0.54 o 2 and 0.7468gNH 4 h 2 PO 4 Mix thoroughly by magnetic stirring;

[0022] 2. Sinter the homogeneously mixed materials in step 1 for 5 hours at an air flow rate of 200ml / min, a heating rate of 1°C / min, and a sintering temperature of 400°C to finally obtain NH 4 h 2 PO 4 Surface-modified lithium-rich manganese-based cathode materials.

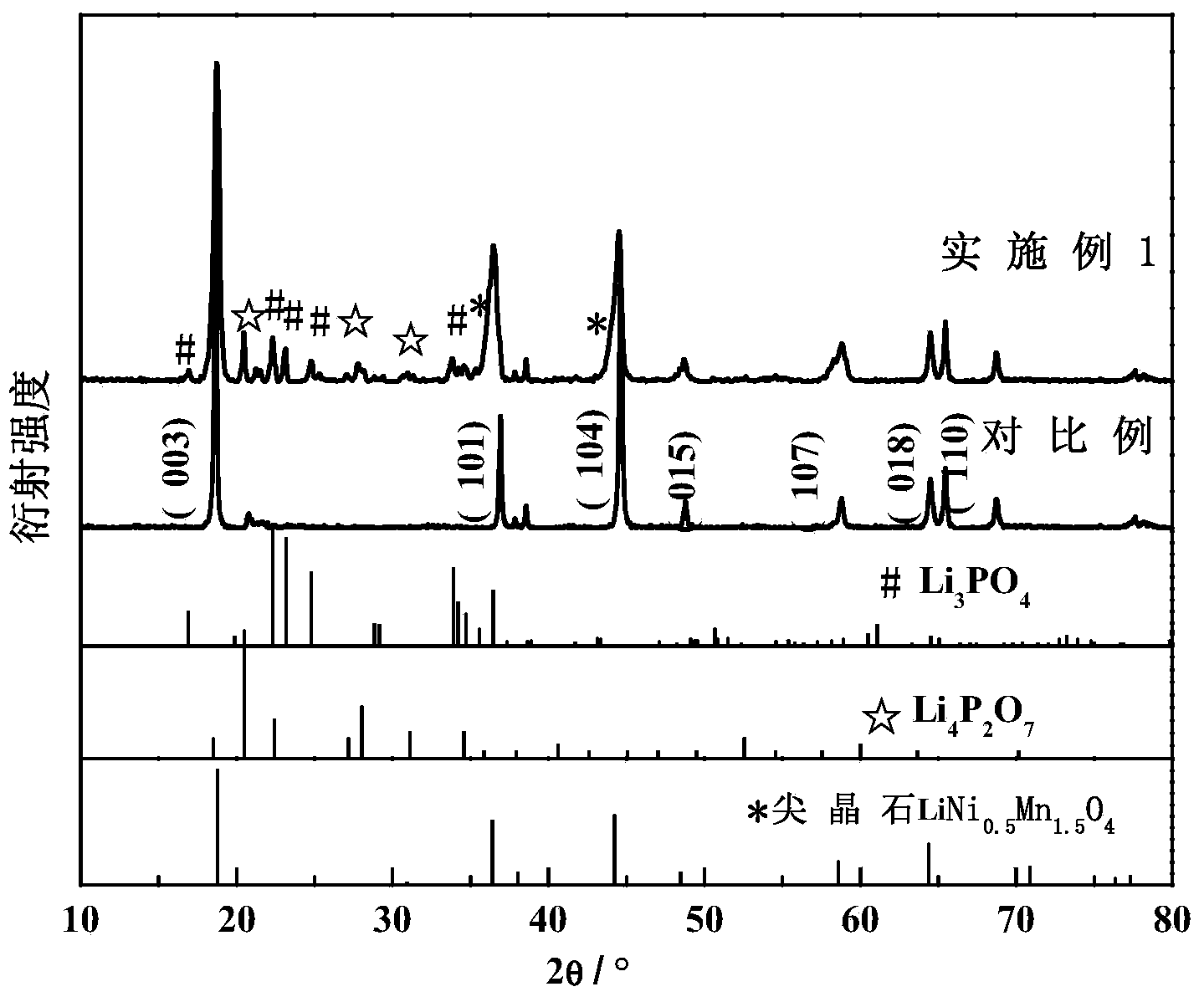

[0023] X-ray diffraction (XRD) analysis shows that the product is a lithium-rich manganese-based positive electrode material with high crystallinity and no impurity phase formation. After modification by phosphate, Li 3 PO 4 Phase, Li 4 P 2 o 7 phase and spinel phase (see figure 1 ), these phases exist on the surface of lithium-rich manganese-based cathode material particles, and Li 3 PO 4 Phase, Li 4 P 2 o 7 Both the spinel phase and the spinel phase have a high lithium ion transport coefficient, so the lithium-rich manganese-bas...

Embodiment 2

[0025] 1. Put 5g of lithium-rich manganese-based cathode material Li 1.2 Ni 0.13 co 0.13 mn 0.54 o 2 and 0.1867gNH 4 h 2 PO 4 Mix thoroughly by magnetic stirring;

[0026] 2. Sinter the homogeneously mixed materials in step 1 for 5 hours at an air flow rate of 200ml / min, a heating rate of 1°C / min, and a sintering temperature of 400°C to finally obtain NH 4 h 2 PO 4 Surface-modified lithium-rich manganese-based cathode materials.

[0027] The lithium-rich manganese-based positive electrode material prepared in the experiment has a spherical shape, complete particles, no obvious crushing or agglomeration, and the particle size is about 15-20um (see figure 2 ), the modified lithium-rich manganese-based cathode material better maintains the spherical morphology of the lithium-rich manganese-based cathode material (see image 3 ).

[0028] The first coulombic efficiency of the surface phosphate-modified lithium-rich manganese-based cathode material at a current density...

Embodiment 3

[0031] 1. Put 5g of lithium-rich manganese-based cathode material Li 1.2 Ni 0.13 co 0.13 mn 0.52 Mg 0.02 o 2 and 0.2800g NH 4 h 2 PO 4 Mix thoroughly by magnetic stirring;

[0032] 2. Sinter the homogeneously mixed material in step 1 for 5 hours under the conditions of air flow rate of 300ml / min, heating rate of 5°C / min, and sintering temperature of 500°C to finally obtain NH 4 h 2 PO 4 Surface-modified lithium-rich manganese-based cathode materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com