Preparation method of cottonseed meal albumen powder through ultraviolet phenol reduction

A protein powder and cottonseed meal technology, applied in protein food processing, vegetable protein processing, protein food ingredients and other directions, can solve the problems of high cost, long processing cycle, no cottonseed meal, etc., and achieve low cost and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing cottonseed meal protein powder with ultraviolet phenol reduction, the steps are:

[0022] (1) Take 8kg of cottonseed cake, add 12kg of water to refine it, and obtain a cottonseed cake slurry;

[0023] (2) Add 8.0 g of cellulase and 4.0 g of hemicellulase to the cottonseed cake slurry, mix well, control the temperature at 50°C, and hold for 7.0 hours;

[0024] (3) Place the enzymatically hydrolyzed cottonseed cake slurry in an annular sports field with ultraviolet rays. The flow rate of the cottonseed cake slurry is 0.1m / s and the thickness is 5mm. 16 Hz ultraviolet radiation for 1.5h, then adjust the flow rate to 0.01m / s, the thickness to 20mm, after 8.0×10 15 Hz ultraviolet radiation 6.0h. The irradiated cottonseed cake slurry is spray-dried to obtain cottonseed cake protein powder.

Embodiment 2

[0026] A kind of preparation method of the cottonseed meal protein powder of ultraviolet phenol reduction, its steps are:

[0027] (1) Take 10kg of cottonseed cake, add 16kg of water to refine it, and obtain a cottonseed cake slurry;

[0028] (2) Add 11.0 g of cellulase and 8.0 g of hemicellulase to the cottonseed cake slurry, mix well, control the temperature at 55°C, and hold for 7.5 hours.

[0029] (3) The enzymatically hydrolyzed cottonseed cake slurry is placed in a circular sports field with ultraviolet rays. The flow rate of the cottonseed cake slurry is 0.08m / s and the thickness is 5mm. 16 Hz ultraviolet radiation for 2.0 h, then adjust the flow rate to 0.01m / s, adjust the thickness to 20mm, after 8.0×10 15 Hz ultraviolet radiation was irradiated for 7.5 hours, and the irradiated cottonseed cake slurry was spray-dried to obtain cottonseed cake protein powder.

Embodiment 3

[0031] A method for preparing cottonseed meal protein powder with ultraviolet phenol reduction, the steps are:

[0032] (1) Take 11kg of cottonseed cake and add 18kg of water to refine it.

[0033] (2) Add 19.0 g of cellulase and 10.0 g of hemicellulase to the cottonseed cake slurry, mix well, and control the temperature at 60°C. The holding time is 9.0 h.

[0034] (3) The enzymatically hydrolyzed cottonseed cake slurry is placed in a circular sports field with ultraviolet rays. The flow rate of the cottonseed cake slurry is 0.08m / s and the thickness is 5mm. 15 Hz ultraviolet radiation for 1.0h, then adjust the flow rate to 0.01m / s, adjust the thickness to 20mm, after 4.0×10 16 Hz ultraviolet radiation was irradiated for 8.0 hours, and the irradiated cottonseed cake slurry was spray-dried to obtain cottonseed cake protein powder.

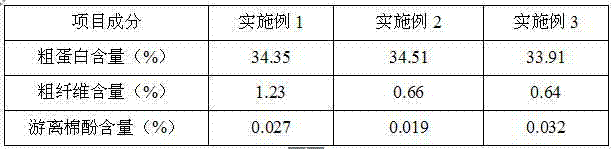

[0035] For the cottonseed cake protein powder obtained in the above three examples, the free gossypol content, crude protein content and crud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com