Multitube large power cracking reactor

A pyrolysis reactor and high-power technology, which is applied in the field of multi-tube high-power pyrolysis reactors, can solve the problems of large size, decreased thermal efficiency of the electric heating system, and increased costs, so as to alleviate carbon deposition in the pyrolysis reaction, facilitate layout and installation, and increase service life. prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

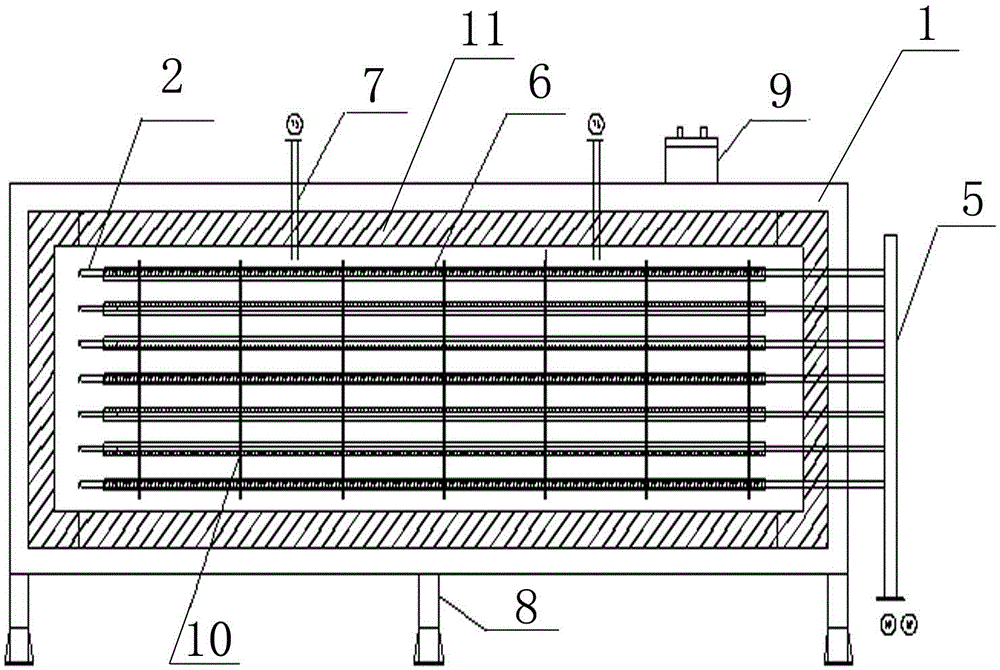

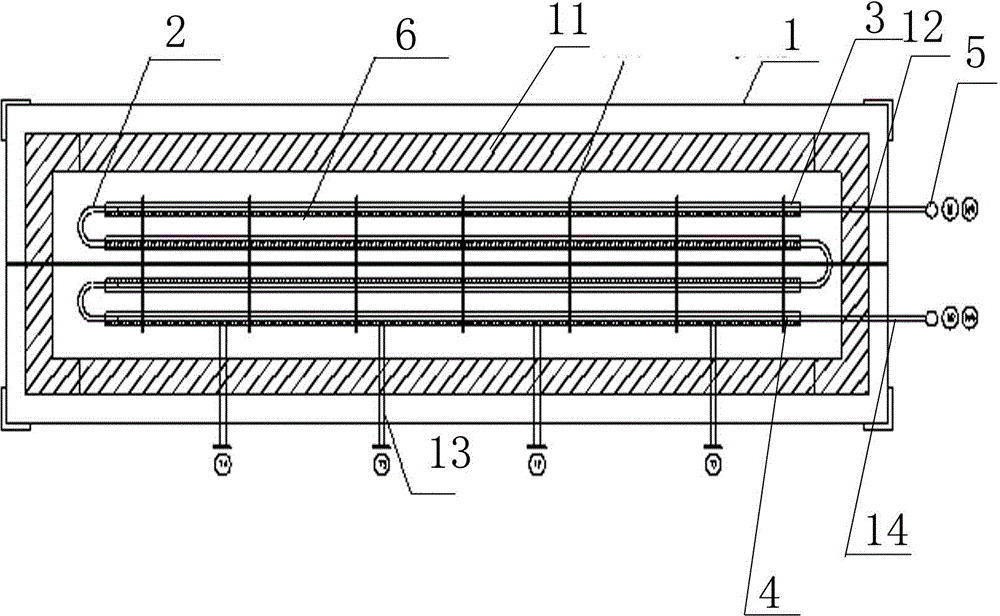

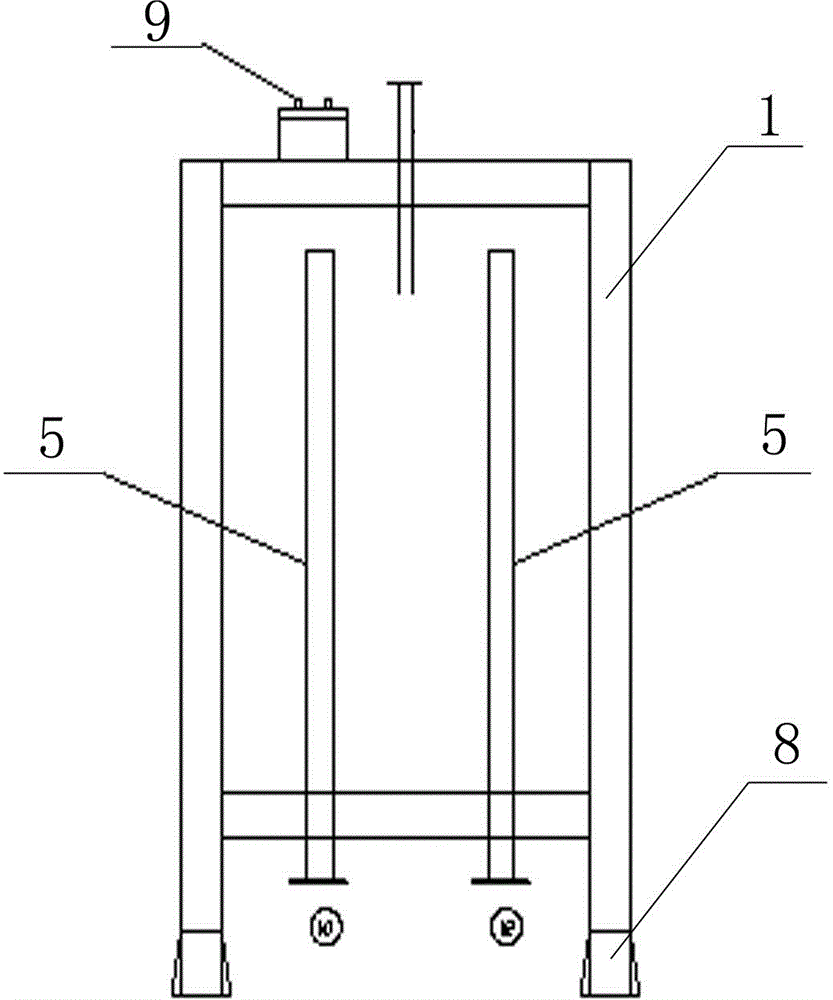

[0009] Embodiment one, in figure 1 , figure 2 and image 3 Among them, the present invention provides a multi-tube high-power cracking reactor, which includes a shell 1, the shell 1 is carbon steel, the bottom of the shell 1 is provided with a skid leg 8, and in the shell 1 A reactor tube is provided, and the shell and the reactor tube constitute a reactor skid. The reactor tube is composed of seven layers of horizontal tube units, and each layer of tube units includes two U-shaped nickel tubes 2, two Two U-shaped nickel tubes 2 are connected in series to form a tube unit, each U-shaped nickel tube 2 includes two nickel tubes, and the two nickel tubes are connected by a U-shaped joint to form a U-shaped nickel tube 2, which is vertically fixed in the housing 1 There are several fixed tube plates 10, and the U-shaped nickel tubes 2 of several layered tube units pass through the tube holes on the fixed tube plate 10 and are fixed in the shell 1. The head and tail of each laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com