Mineral processing process of low-grade micro-fine particle embedded iron ore hard to choose

A fine-grained, low-grade technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of high iron grade in tailings, low recovery rate of iron concentrate, and low grade iron in concentrate. The effect of reducing the dosage of chemicals, shortening the flotation process and improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

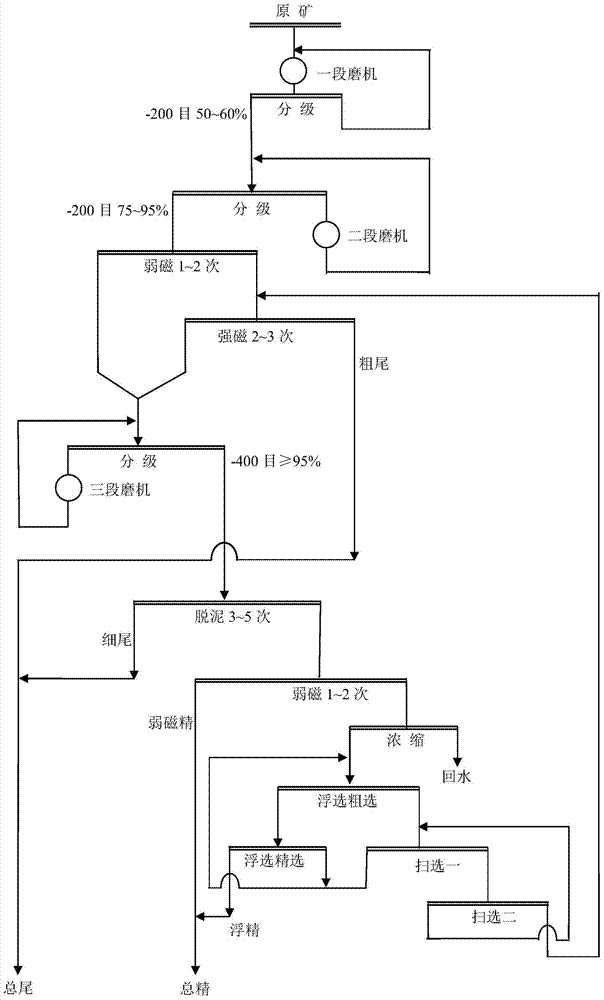

[0031] A beneficiation plant for refractory iron ore has an annual processing capacity of 300,000 t / year. The iron minerals in the ore in the area have a fine particle size, and the magnetite belongs to the category of fine-grained to fine-grained particles, and the particle size is mostly between 0.01 and 0.03 between mm; while hematite is distributed in the gangue in a fine disseminated shape, with the characteristics of fine particles to extremely fine particles, except for a few particles that can reach about 0.04mm, the particle size of most particles is distributed between 0.002mm and Between 0.03mm. use as figure 1 The beneficiation process of the low-grade micro-grain embedding refractory iron ore of the present invention as shown, specifically comprises the following steps:

[0032] (1) One-stage grinding and grading: After the raw ore is crushed to <12mm, it first passes through a closed-circuit grinding and grading system for one-stage grinding and grading, and the...

Embodiment 2

[0041] A beneficiation plant for refractory iron ore has an annual processing capacity of 2 million t / year. The iron minerals in the ore are mainly hematite and magnetite, followed by semi-false to false hematite, and occasionally sporadic limonite Distribution; gangue minerals are mainly quartz, followed by feldspar, chlorite, sericite, actinolite and apatite. The magnetite in the ore in the area belongs to the category of fine-grained to fine-grained embedded distribution, and the particle size is mostly between 0.01mm-0.03mm, and some are 0.04mm-0.15mm, which belongs to the category of fine-grained embedded distribution; while hematite is crystal The particle size is very small, and the particle size distribution of most particles is between 0.002mm and 0.01mm, which belongs to the category of extremely fine particle embedded cloth. use as figure 1 The beneficiation process of the low-grade micro-grain embedding refractory iron ore of the present invention as shown, specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com