Centrifugal casting method for asymmetric annular high-lead bronze casting

A technology of bronze casting and centrifugal casting, which is applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of alloy casting with disparity in melting point, difficulty in casting high-lead bronze, regional segregation, etc., achieve good mechanical properties, solve problems High-lead bronze alloy segregation problem, high production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

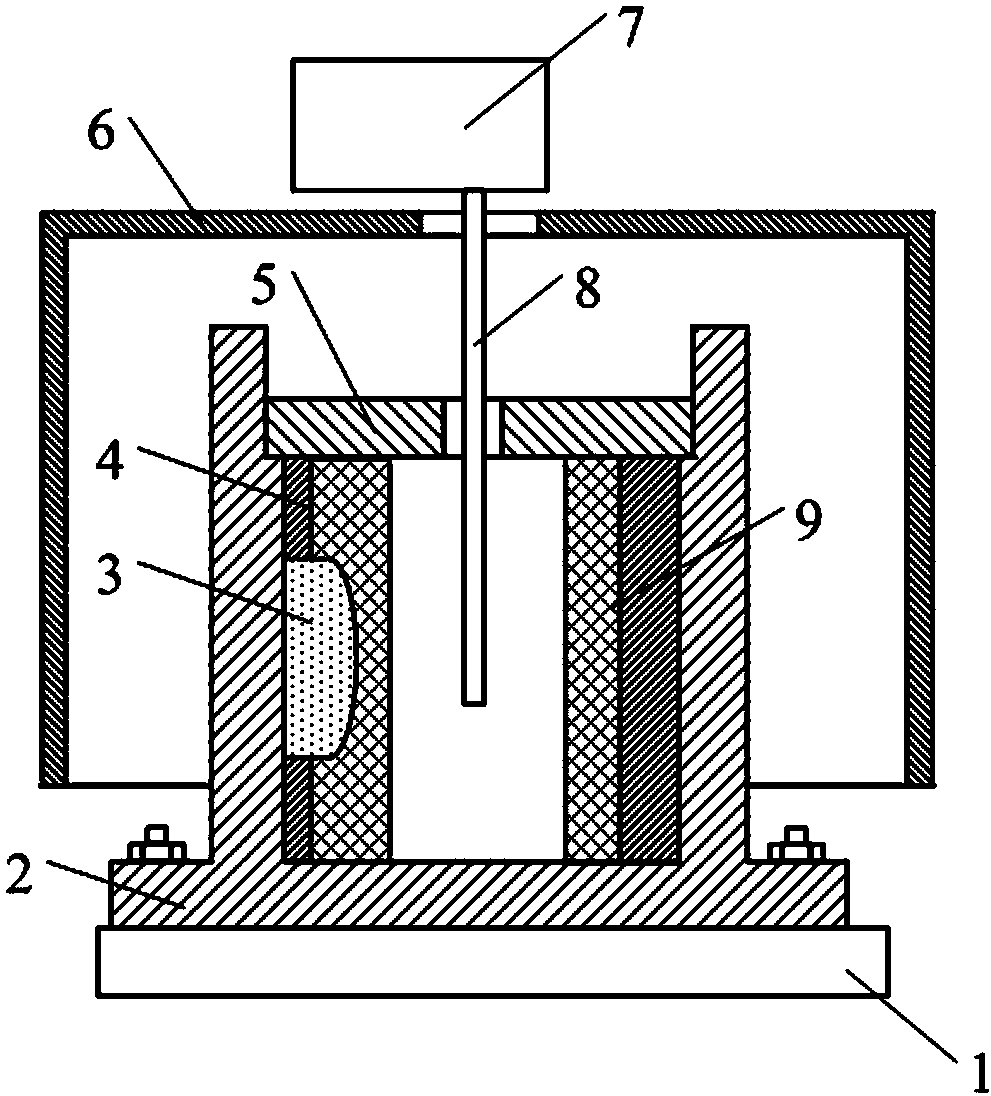

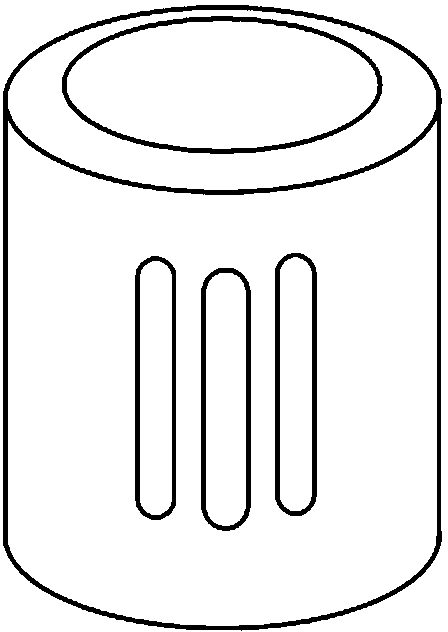

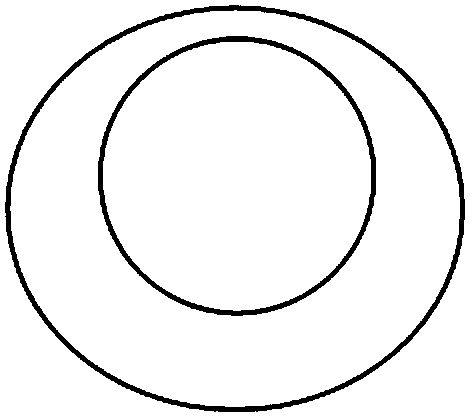

[0046] Centrifugal casting device structure such as figure 1 shown; the centrifugal casting machine 1 is provided with an outer mold 2, and the outer mold 2 is provided with an inner mold 4, and the outer mold 2 is provided with a special-shaped portion 3, and the special-shaped portion 3 passes through the inner mold 4 and is bonded with the outer mold 2; The top of the outer mold 2 is connected with the mold cover 5, the outer mold 2, the inner mold 4 and the mold cover 5 are provided with a protective cover 6, and the pouring nozzle 8 below the pouring box 7 is inserted into the inner mold through the protective cover 6 and the mold cover 5 4 internal;

[0047] The mold cover and the outer mold are made of cast iron; the inner mold is made of cast iron; the special-shaped part is made of refractory material; the special-shaped part is bonded to the outer mold through refractory mud;

[0048] The refractory material is high siliceous refractory material; the refractory mud...

Embodiment 2

[0059] Centrifugal casting device structure is the same as embodiment 1, the difference is:

[0060] (1) There is no inner mold;

[0061] (2) The material of the special-shaped part is aluminum refractory material; the refractory mud is aluminum refractory mud;

[0062] Centrifugal casting method is the same as embodiment 1, and difference is:

[0063] (1) The composition of the alloy melt conforms to the composition of the brand ZCuPb15Sn8 alloy;

[0064] (2) Set the casting allowance of the outer surface and the lower surface of the cast part to be 4mm on one side, and the casting allowance on the upper surface of the cast part to be 6mm on one side;

[0065] (3) The coating is made by mixing 55 parts of mullite, 2 parts of flake graphite, 0.4 parts of coal tar and 33 parts of silica sol;

[0066] (4) The temperature T when the alloy raw material for casting is completely melted 0 is 1060°C, the selected value of A is 160°C, and the casting temperature T 1 is 1220°C; ...

Embodiment 3

[0072] Centrifugal casting device structure is the same as embodiment 1, the difference is:

[0073] (1) There are no special-shaped parts;

[0074] Centrifugal casting method is the same as embodiment 1, and difference is:

[0075] (1) The composition of the alloy melt conforms to the composition of the brand ZCuPb10Sn10 alloy;

[0076] (2) Set the casting allowance of the outer surface and the lower surface of the cast part to be 5mm on one side, and the casting allowance on the upper surface of the cast part to be 8mm on one side;

[0077] (3) Coating paint on the inner surface of the casting mold; the paint is made by mixing 50 parts of mullite, 4 parts of flake graphite, 0.6 parts of coal tar and 35 parts of silica sol;

[0078] (4) The temperature T when the alloy raw material for casting is completely melted 0 is 1080°C, the selected value of A is 100°C, and the casting temperature T 1 is 1180°C;

[0079] The selected value of the gravity coefficient G is 1000; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com