Process adopting extra-fine steel wire to cut silicon rod

A technology of wire cutting and multi-wire cutting machines, applied in the direction of fine working devices, manufacturing tools, stone processing equipment, etc., can solve the problems of large consumption of consumables, high cutting costs, and low production rate, so as to improve the cutting capacity , Reduce cutting consumption and wear, improve the effect of film output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

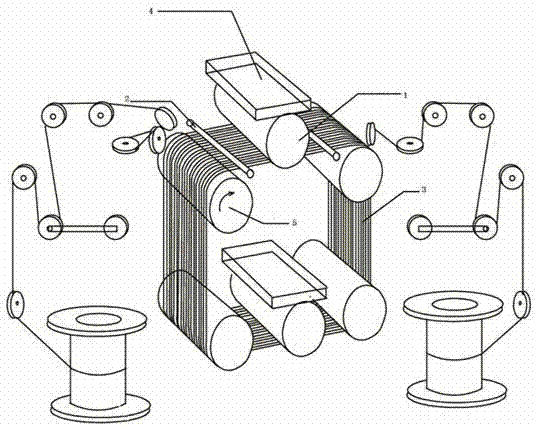

Image

Examples

Embodiment 1

[0032] The main equipment and raw materials in this embodiment are: multi-wire cutting machine model: MWM442DM produced by NTC; raw materials: 156S monocrystalline silicon rod, outer diameter 200mm, side length 156mm, length 330mm, main roller 5 groove pitch 325μm.

[0033] The goal is to use ultra-fine 0.10mm (diameter) steel wires to cut silicon wafers. The specification is 200μm thick monocrystalline silicon wafers. The above-mentioned equipment cutting process is used. The specific steps are as follows:

[0034] (1) Mortar configuration: Dry silicon carbide at a temperature of 60-100°C and a drying time of more than 360 minutes. This example uses 400 minutes. Calculate the amount of cutting fluid and silicon carbide according to the ratio. The mass ratio is 1:0.9 for configuration, and the mortar configuration is carried out in the mixing tank. The mixing time is 6 hours. The cutting fluid can be the crystal silicon cutting fluid of Ningjin Fine Chemical;

[0035] (2) Adhe...

Embodiment 2

[0045] The main equipment and raw materials in this embodiment are: multi-wire cutting machine model: PV600 multi-wire cutting machine produced by NTC; raw material: polysilicon rod, side length 156mm, length 650mm, main roller groove pitch 328μm.

[0046]The specifications of the target cutting polysilicon wafers are 195 μm in thickness, and the following is to cut the silicon wafers with a cutting wire with a diameter of 0.10 mm.

[0047] Using the above equipment to cut solar silicon wafers with ultra-thin steel wires is as follows:

[0048] (1) Mortar configuration: Dry silicon carbide at a temperature of 60-100°C and a drying time of more than 360 minutes. This example uses 400 minutes. Calculate the amount of cutting fluid and silicon carbide according to the ratio. The mass ratio is 1:1.0 for configuration, and the mortar configuration is carried out in the mixing tank. The mixing time is 6 hours. The cutting fluid can be the crystal silicon cutting fluid of Ningjin Fin...

Embodiment 3

[0057] The main equipment and raw materials in this embodiment are: multi-wire cutting machine model: PV800 produced by NTC; raw material: 156SR monocrystalline silicon rod, the groove distance of the main roller is 327μm, and the specification of the target cutting silicon wafer is 0.2mm in thickness. The diameter used is as follows: 0.10mm cutting line for silicon wafer cutting.

[0058] Using the ultra-fine steel wire cutting process of the above equipment, the specific steps are as follows:

[0059] (1) Mortar configuration: Dry silicon carbide at a temperature of 60-100°C and a drying time of more than 360 minutes. This example uses 400 minutes. Calculate the amount of cutting fluid and silicon carbide according to the ratio. The mass ratio is 1:1.2 for configuration, and the mortar configuration is carried out in the mixing tank, and the mixing time is 6h;

[0060] (2) Sticking stick: Sticking stick: silicon stick is glued with silicon stick, the curing agent and glue a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com