Blue-proof hardening film

A technology of anti-blue light and hardening film, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, coatings, etc., can solve the problems of high cost, complex process of anti-blue light protective film, low ultraviolet absorption rate, etc., and achieve low cost , good anti-ultraviolet effect and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

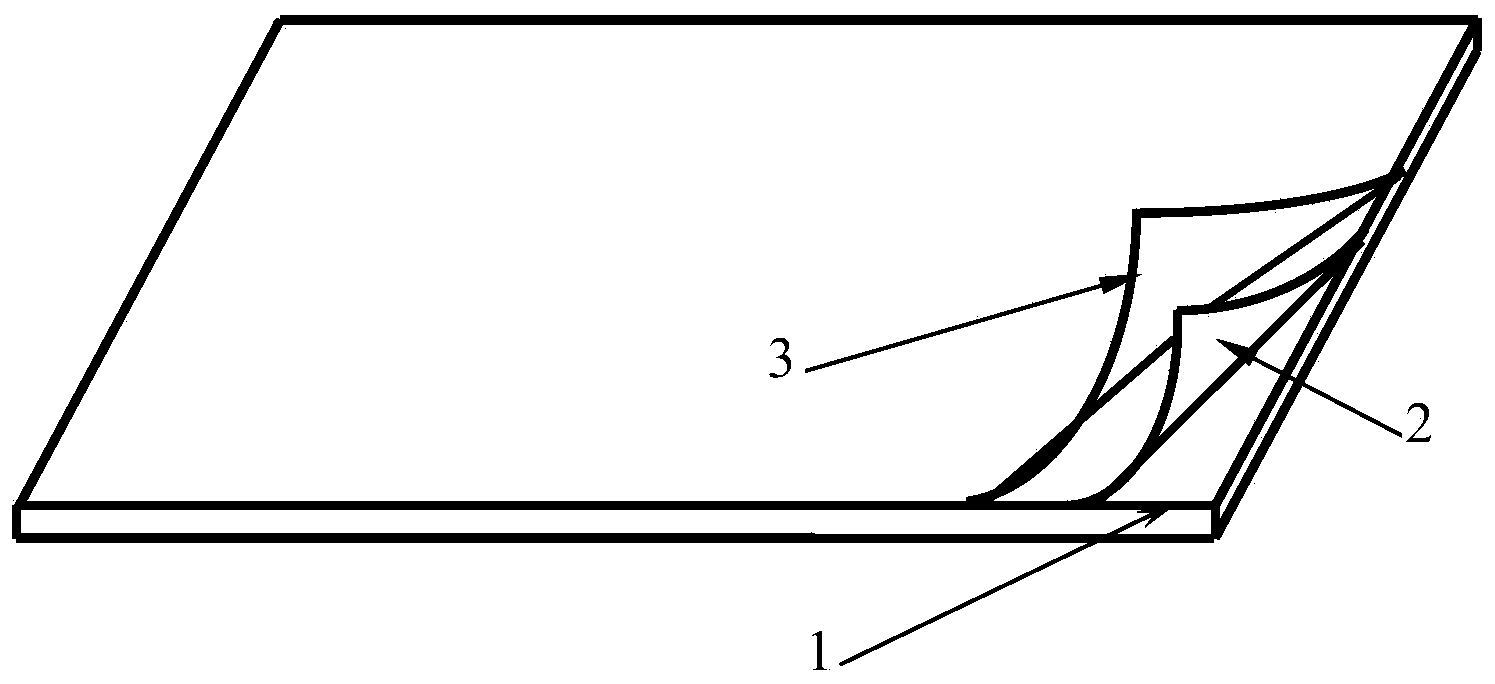

Image

Examples

Embodiment 1

[0054] The base film is made of PET with a thickness of 220um.

[0055] The thickness of the anti-ultraviolet coating is 15um, and the percentages of each component and each component in the total weight of the coating liquid are as follows: ultraviolet absorber UV-P, 2%; nano-titanium dioxide, 1%; 704# curing agent, 5%; Urethane Acrylate Resin, 50%; Dispersant, 0.5%; Stabilizer, 0.15%; Xylene, 11.35%; Ethyl Acetate, 30%.

[0056] The thickness of the anti-blue light hardening coating is 15um, and the percentages of each component and each component in the total mass of the coating are as follows: black essence, 1%; yellow phosphor, 0.5%; photoinitiator 184, 2%; photoinitiator Agent ITX, 1%; Polyester acrylate, 30%; TPGDA, 15%; TMPTA, 15%; Leveling agent, 0.3%; Wetting and dispersing agent, 0.2%; Dichloroethane, 19.5%. Example 2

Embodiment 2

[0057] The base film is made of PET with a thickness of 220um.

[0058] The thickness of the anti-ultraviolet coating is 10um, and the percentages of each component and each component in the total weight of the coating solution are as follows: nano-titanium dioxide, 1.5%; pearl powder, 1%; benzoyl peroxide, 0.2%; 705# curing agent, 10%; polyurethane acrylate resin, 50%; dispersant, 0.5%; anti-reflection agent, 0.5%; ethyl acetate, 25%; dichloroethane, 11.3%.

[0059] The thickness of the anti-blue light hardening coating is 20um, and the percentages of each component and each component in the total weight of the coating liquid are as follows: black essence, 1%; yellow essence, 0.5%; photoinitiator 184, 1.5%; photoinitiator 1173, 1.5%; aliphatic polyurethane hexaacrylate, 15%; epoxy acrylate, 15%; HDDA, 25%; wetting and dispersing agent, 0.2%; anti-reflection agent, 0.5%; adhesion promoter, 0.15%; Ethyl acetate, 30%; Toluene, 9.65%.

Embodiment 3

[0061] The base film is made of PET with a thickness of 220um.

[0062] The thickness of the anti-ultraviolet coating is 10um, and the percentages of each component and each component in the total weight of the coating solution are as follows: nano-titanium dioxide, 2%; photochromic MC powder, 1%; methyl ethyl ketone peroxide, 0.3%, 704# curing agent, 5%; urethane acrylate resin, 30%; epoxy resin, 20%; stabilizer, 0.15%; dispersant, 0.15%; 21.25%.

[0063] The thickness of the anti-blue light hardening coating is 20um, and the percentages of each component and each component in the total weight of the coating liquid are as follows: black essence, 0.8%; green phosphor, 0.8%; photoinitiator 819, 1%; photoinitiator ITX, 2%; modified epoxy acrylate, 15%; epoxy acrylate, 15%; HDDA, 15%; TPGDA, 15%; wetting and dispersing agent, 0.15%; anti-reflection agent, 0.5%; adhesion Accelerator, 0.15%; Ethyl acetate, 25%; Butyl acetate, 10.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com