Self-supported reduced graphene oxide paper and preparation method thereof

A graphene paper, self-supporting technology, applied in the direction of graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of long time consumption, low yield, hindering the transfer and application of graphene film, etc., to achieve high purity and good mechanics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

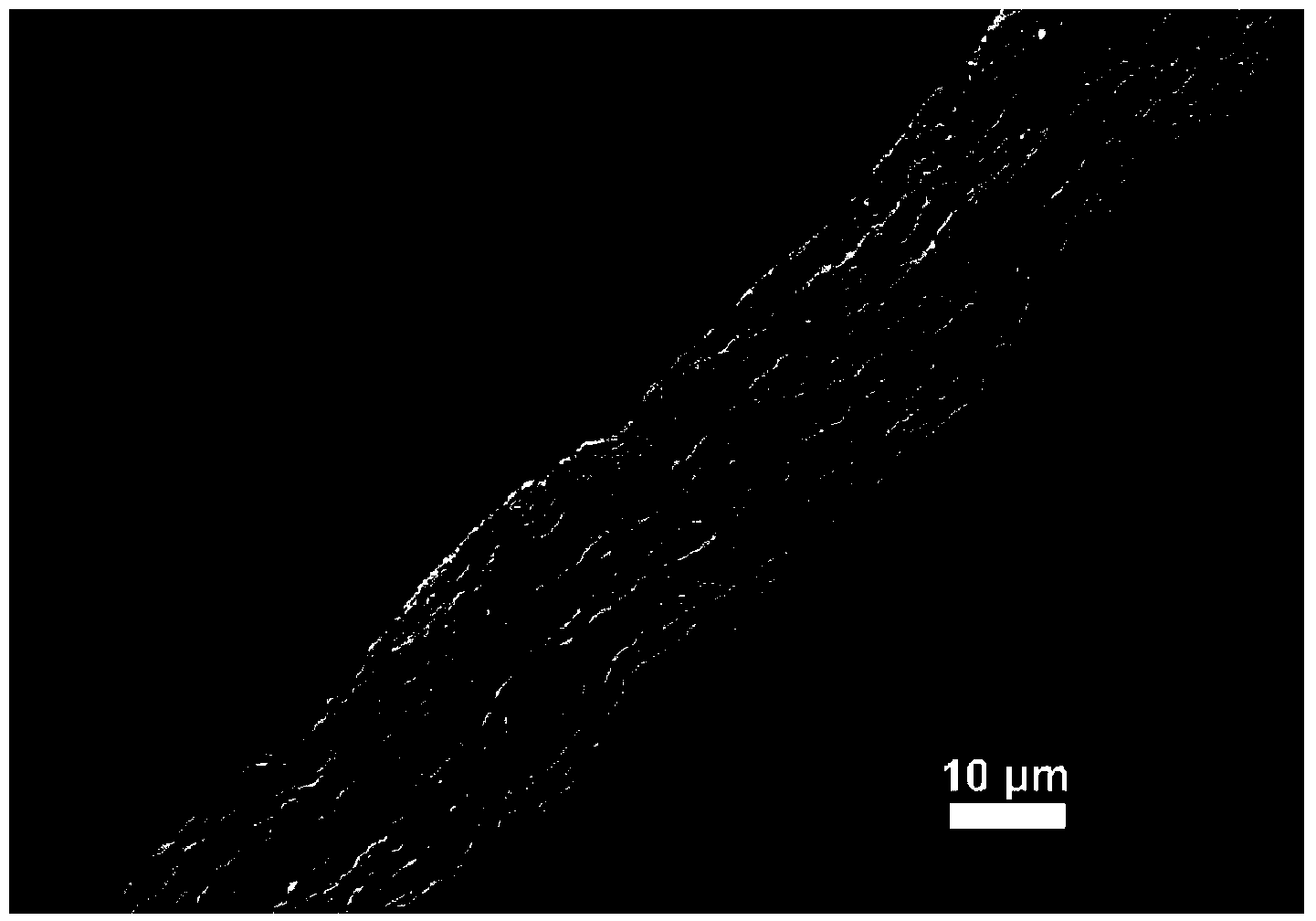

[0027] The self-supporting reduced graphene oxide paper preparation method of the embodiment of the present invention 1 comprises the following steps:

[0028] (a) At room temperature, disperse 600mg of graphite oxide in 600mL of water, then add 1.5g of sodium dodecylbenzenesulfonate, and obtain a graphite oxide dispersion with a concentration of 1mg / mL after ultrasonic treatment for 1 to 3 hours; Add 3 mL of hydrazine hydrate to the graphite oxide dispersion, heat the oil bath to 100°C, and react for 14 hours to obtain a black reduced graphene oxide suspension;

[0029] (b) Lower the reaction temperature in the oil bath to 80°C, add 7.31g of aminobenzoic acid and 3.15g of isoamyl nitrite to the reduced graphene oxide suspension obtained in step (a), and react in the oil bath for at least 10 hours to obtain Hydroxy-modified reduced graphene oxide dispersion;

[0030] (c) Suction filter the hydroxyl-modified reduced graphene oxide dispersion obtained in step (b), then wash the...

Embodiment 2

[0034] The self-supporting reduced graphene oxide paper preparation method of the embodiment of the present invention 2 comprises the following steps:

[0035] (a) At room temperature, disperse 300mg of graphite oxide in 600mL of water, then add 1.5g of sodium dodecylbenzenesulfonate, and obtain a graphite oxide dispersion with a concentration of 0.5mg / mL after ultrasonic treatment for 1 to 3 hours; Add 3 mL of hydrazine hydrate to the above graphite oxide dispersion, heat the oil bath to 100°C, and react for 14 hours to obtain a black reduced graphene oxide suspension;

[0036] (b) Lower the reaction temperature in the oil bath to 80°C, add 7.31g of aminobenzoic acid and 3.15g of isoamyl nitrite to the reduced graphene oxide suspension obtained in step (a), and react in the oil bath for at least 10 hours to obtain Hydroxy-modified reduced graphene oxide dispersion;

[0037] (c) Suction filter the hydroxyl-modified reduced graphene oxide dispersion obtained in step (b), then ...

Embodiment 3

[0041] The self-supporting reduced graphene oxide paper preparation method of the embodiment of the present invention 3 comprises the following steps:

[0042] (a) At room temperature, disperse 600mg of graphite oxide in 600mL of water, then add 6g of sodium dodecylbenzenesulfonate, and obtain a graphite oxide dispersion with a concentration of 1mg / mL after ultrasonic treatment for 1 to 3 hours; Add 3 mL of hydrazine hydrate to the graphite dispersion, heat the oil bath to 100°C, and react for 14 hours to obtain a black reduced graphene oxide suspension;

[0043] (b) Lower the reaction temperature in the oil bath to 80°C, add 7.31g of aminobenzoic acid and 3.15g of isoamyl nitrite to the reduced graphene oxide suspension obtained in step (a), and react in the oil bath for at least 10 hours to obtain Hydroxy-modified reduced graphene oxide dispersion;

[0044] (c) Suction filter the hydroxyl-modified reduced graphene oxide dispersion obtained in step (b), then wash the filtrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com