Preparation method of copper sulfide nanowire

A copper sulfide and nanowire technology, applied in copper sulfide, nanotechnology, nanotechnology and other directions, can solve problems such as unfavorable large-scale synthesis, inability to synthesize in one step, cumbersome operation process, etc., achieving simple synthesis method and reaction device, and green reaction process. , the effect of cleaning the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

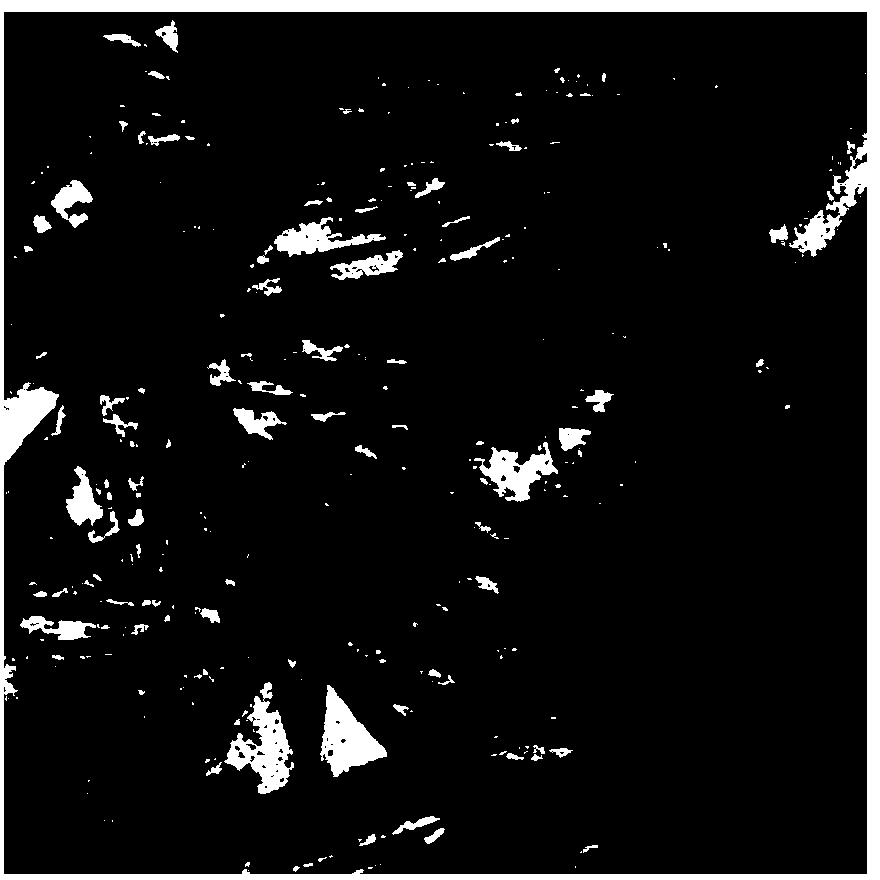

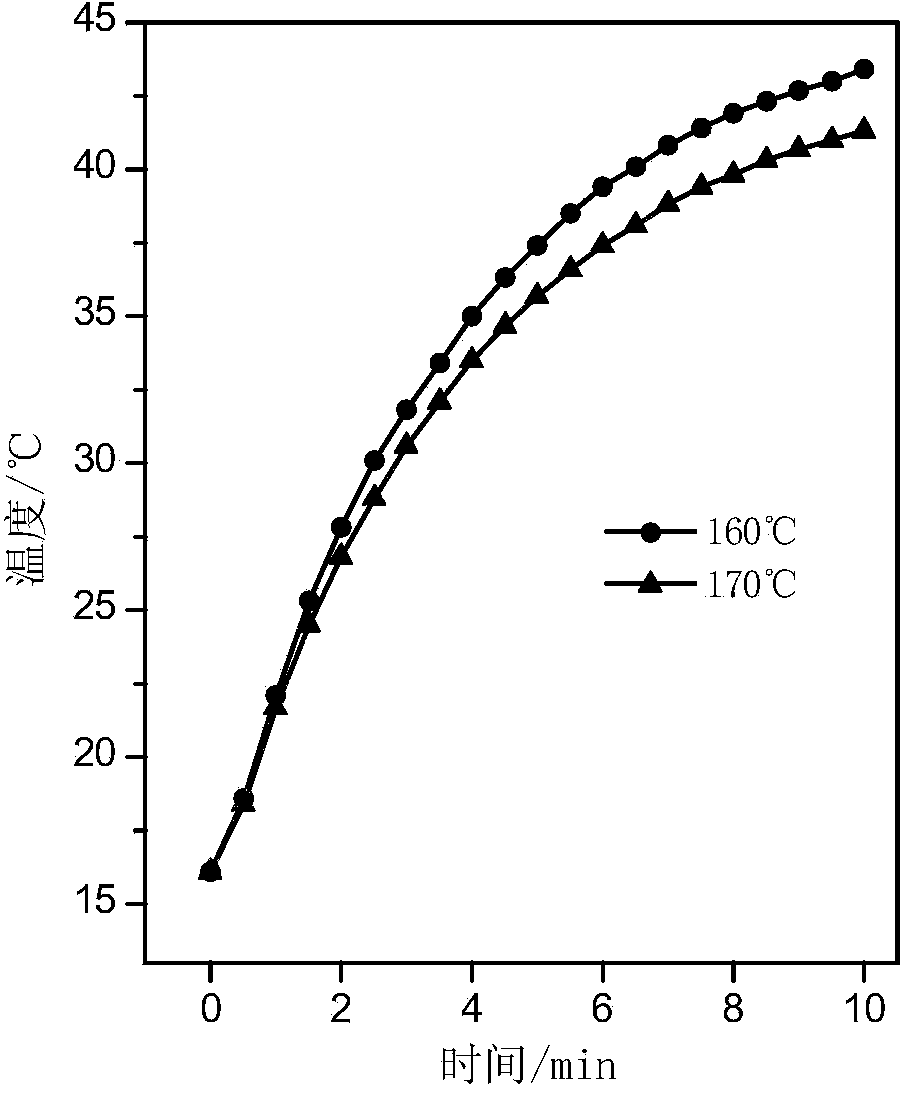

Embodiment 1

[0025] (1) In a 50ml three-necked bottle, weigh 0.5mmol CuCl 2 2H 2 O and 10ml oleylamine, pass into N 2 Protected, heated to 160°C with stirring, and then kept at constant temperature for 1h.

[0026] (2) Take another 5ml of oleylamine in a test tube, add 0.5mmol (C2H5)2NCSSNa·3H2O(SDEDTC), stir and dissolve at 120°C.

[0027] (3) Inject the solution in (2) into (1) through a syringe pump at a rate of 30ml / h, and react at a constant temperature for 1h.

[0028] (4) Cool the obtained product to 60°C, centrifuge in a 10ml centrifuge tube, wash twice with cyclohexane, and finally disperse in 10ml chloroform, which is the hydrophobic product.

[0029] (5) Use 2ml of a chloroform solution containing 20mg of polyethylene glycol monomethyl etherified-1,2-distearate-3-phosphatidylethanolamine (SDEDTC) and 1ml of the hydrophobic product in (4), after stirring for 2 hours, put The obtained product was placed in a rotary evaporator, vacuum-dried and spin-dried at room temperature, a...

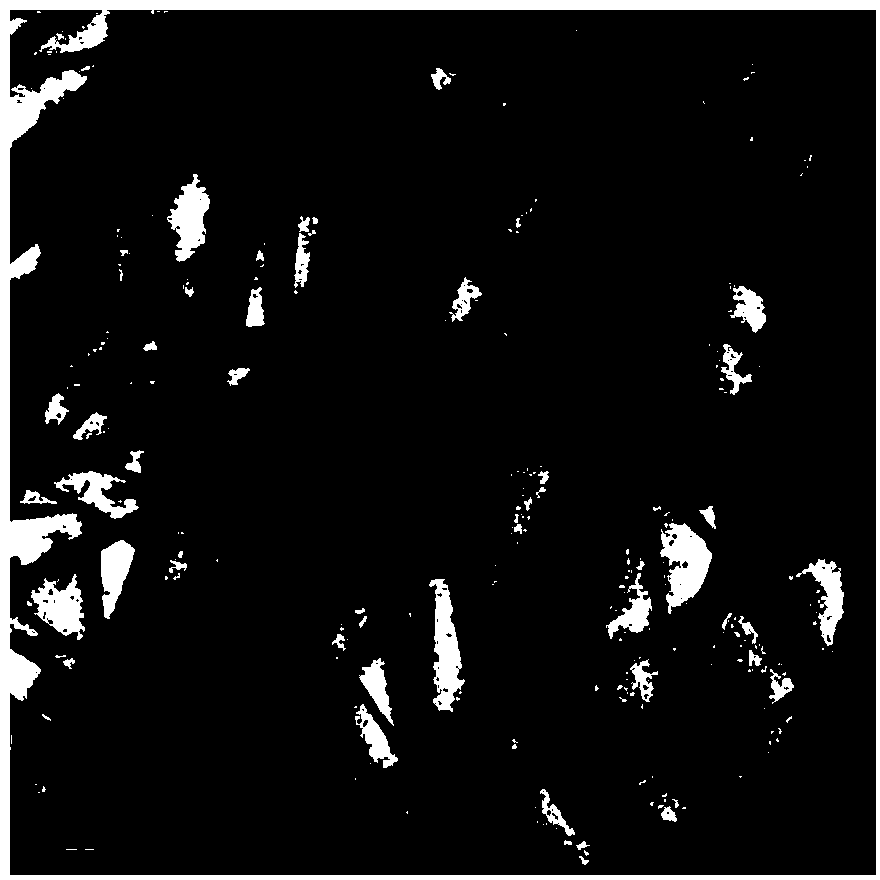

Embodiment 2

[0033] (1) In a 50ml three-necked bottle, weigh 0.5mmol CuCl 2 2H 2 O and 10ml oleylamine, pass into N 2 Protected, heated to 170°C while stirring, and then kept at constant temperature for 1h.

[0034] (2) Take another 5ml of oleylamine in a test tube, add 0.5mmol (C 2 h 5 ) 2 NCSSNa·3H 2 O(SDEDTC), stirred and dissolved at 120°C.

[0035] (3) Inject the solution in (2) into (1) through a syringe pump at a rate of 30ml / h, and react at a constant temperature for 1h.

[0036] (4) Cool the obtained product to 60°C, centrifuge in a 10ml centrifuge tube, wash twice with cyclohexane, and finally disperse in 10ml chloroform, which is the hydrophobic product.

[0037] (5) Use 2ml of chloroform solution containing 20mg of polyethylene glycol monomethyl etherified-1,2-distearate-3-phosphatidylethanolamine (DSPE-PEG) and 1ml of the hydrophobic product in (4), after stirring for 2h , the obtained product was placed in a rotary evaporator, vacuum-dried and spin-dried at room tempe...

Embodiment 3

[0041] (1) In a 50ml three-necked bottle, weigh 0.5mmol CuCl 2 2H 2 O and 10ml oleylamine, pass into N 2 Protected, heated to 160°C while stirring, and then kept at constant temperature for 30min.

[0042] (2) Take another 5ml of oleylamine in a test tube, add 0.5mmol (C 2 h 5 ) 2 NCSSNa·3H 2 O(SDEDTC), stirred and dissolved at 120°C.

[0043] (3) Inject the solution in (2) into (1) at a rate of 30ml / h through a syringe pump and react at a constant temperature for 1.5h.

[0044] (4) Cool the obtained product to 60°C, centrifuge in a 10ml centrifuge tube, wash twice with cyclohexane, and finally disperse in 10ml chloroform, which is the hydrophobic product.

[0045] (5) Use 2ml of chloroform solution containing 20mg of polyethylene glycol monomethyl etherified-1,2-distearate-3-phosphatidylethanolamine (DSPE-PEG) and 1ml of the hydrophobic product in (4), after stirring for 2h , the obtained product was placed in a rotary evaporator, vacuum-dried and spin-dried at room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com