A kind of preparation method of copper sulfide nanowire

A technology of copper sulfide and nanowires, applied in the direction of copper sulfide, nanotechnology, nanotechnology, etc., can solve the problems of cumbersome operation process, inability to synthesize in one step, unfavorable large-scale synthesis, etc., and achieve clean reaction process, green reaction process, and synthetic method Simple Effects with React Devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

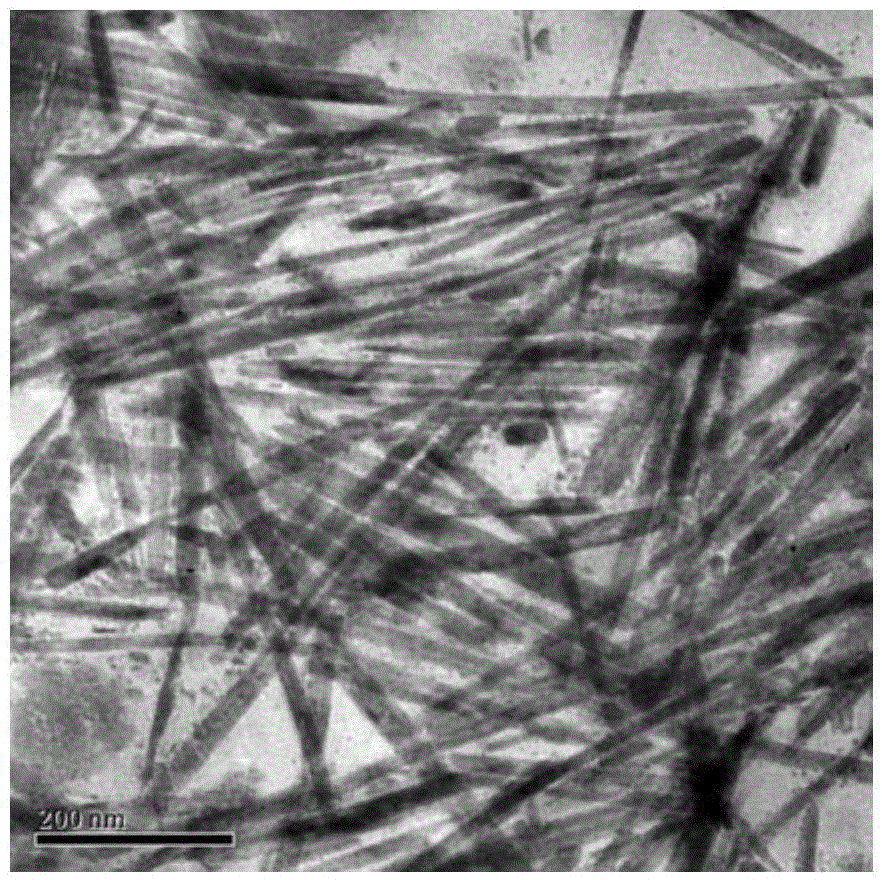

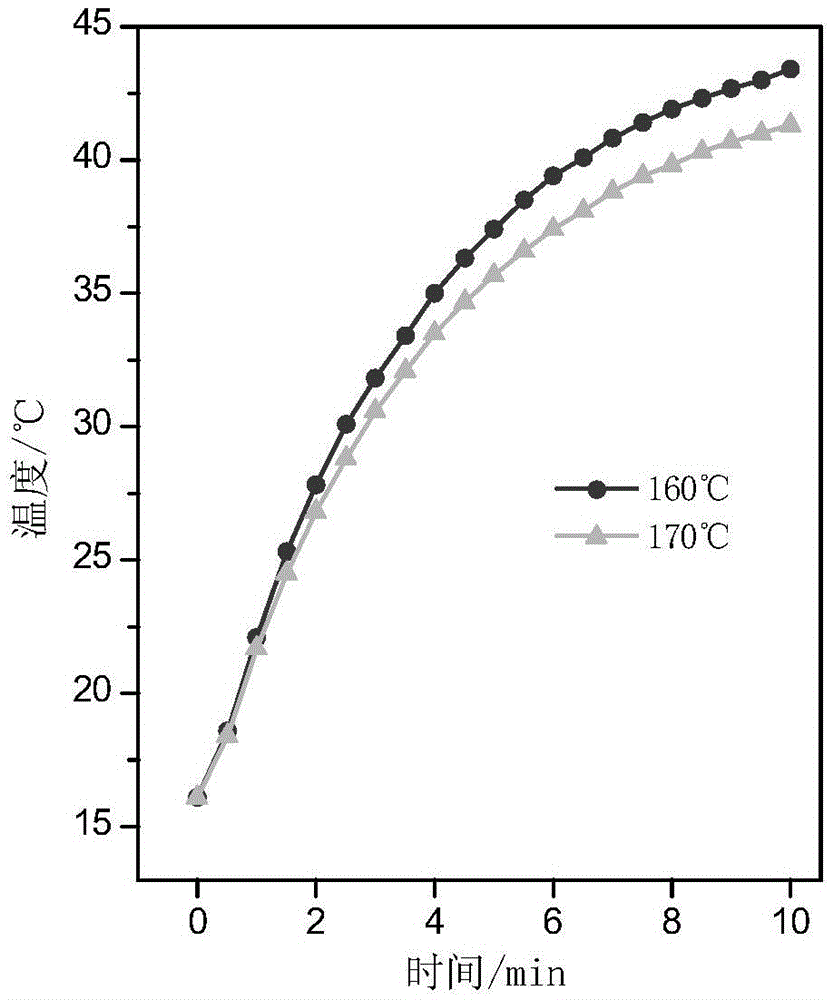

Embodiment 1

[0025] (1) In a 50ml three-necked bottle, weigh 0.5mmol CuCl 2 2H 2 O and 10ml oleylamine, pass into N 2 Protected, heated to 160°C with stirring, and then kept at constant temperature for 1h.

[0026] (2) Take another 5ml of oleylamine in a test tube, add 0.5mmol (C2H5)2NCSSNa·3H2O(SDEDTC), stir and dissolve at 120°C.

[0027] (3) Inject the solution in (2) into (1) through a syringe pump at a rate of 30ml / h, and react at a constant temperature for 1h.

[0028] (4) Cool the obtained product to 60°C, centrifuge in a 10ml centrifuge tube, wash twice with cyclohexane, and finally disperse in 10ml chloroform, which is the hydrophobic product.

[0029] (5) Use 2ml of a chloroform solution containing 20mg of polyethylene glycol monomethyl etherified-1,2-distearate-3-phosphatidylethanolamine (SDEDTC) and 1ml of the hydrophobic product in (4), after stirring for 2 hours, put The obtained product was placed in a rotary evaporator, vacuum-dried and spin-dried at room temperature, a...

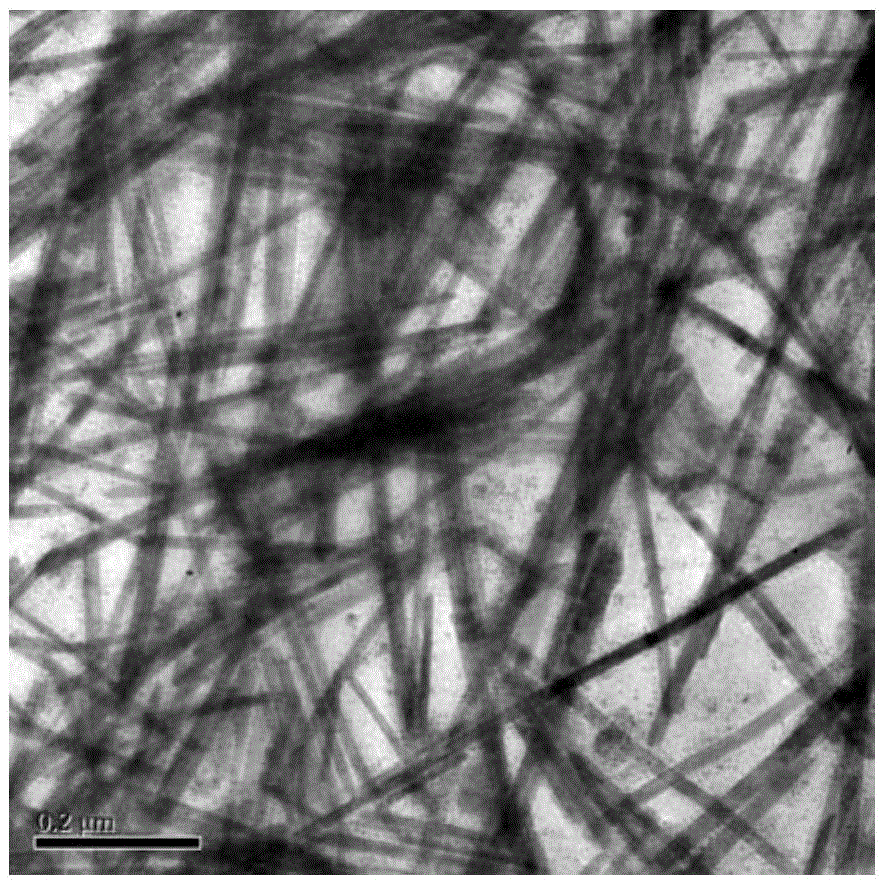

Embodiment 2

[0033] (1) In a 50ml three-necked bottle, weigh 0.5mmol CuCl 2 2H 2 O and 10ml oleylamine, pass into N 2 Protected, heated to 170°C while stirring, and then kept at constant temperature for 1h.

[0034] (2) Take another 5ml of oleylamine in a test tube, add 0.5mmol (C 2 h 5 ) 2 NCSSNa·3H 2 O(SDEDTC), stirred and dissolved at 120°C.

[0035] (3) Inject the solution in (2) into (1) through a syringe pump at a rate of 30ml / h, and react at a constant temperature for 1h.

[0036] (4) Cool the obtained product to 60°C, centrifuge in a 10ml centrifuge tube, wash twice with cyclohexane, and finally disperse in 10ml chloroform, which is the hydrophobic product.

[0037] (5) Use 2ml of chloroform solution containing 20mg of polyethylene glycol monomethyl etherified-1,2-distearate-3-phosphatidylethanolamine (DSPE-PEG) and 1ml of the hydrophobic product in (4), after stirring for 2h , the obtained product was placed in a rotary evaporator, vacuum-dried and spin-dried at room tempe...

Embodiment 3

[0041] (1) In a 50ml three-necked bottle, weigh 0.5mmol CuCl 2 2H 2 O and 10ml oleylamine, pass into N 2 Protected, heated to 160°C while stirring, and then kept at constant temperature for 30min.

[0042] (2) Take another 5ml of oleylamine in a test tube, add 0.5mmol (C 2 h 5 ) 2 NCSSNa·3H 2 O(SDEDTC), stirred and dissolved at 120°C.

[0043] (3) Inject the solution in (2) into (1) at a rate of 30ml / h through a syringe pump and react at a constant temperature for 1.5h.

[0044] (4) Cool the obtained product to 60°C, centrifuge in a 10ml centrifuge tube, wash twice with cyclohexane, and finally disperse in 10ml chloroform, which is the hydrophobic product.

[0045] (5) Use 2ml of chloroform solution containing 20mg of polyethylene glycol monomethyl etherified-1,2-distearate-3-phosphatidylethanolamine (DSPE-PEG) and 1ml of the hydrophobic product in (4), after stirring for 2h , the obtained product was placed in a rotary evaporator, vacuum-dried and spin-dried at room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com