Method and system for recycling vanadium-containing mud generated in vanadium removal process of crude titanium tetrachloride

A technology of crude titanium tetrachloride and recovery method, which is applied in the field of recovery of valuable elements Ti and V, can solve the problems of inability to recover valuable elements vanadium, increase the production cost of sponge titanium, occupy land resources, etc., and achieve simple production equipment, The effect of high product purity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the method and system for recovering the vanadium-containing mud produced by removing vanadium from crude titanium tetrachloride according to the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments.

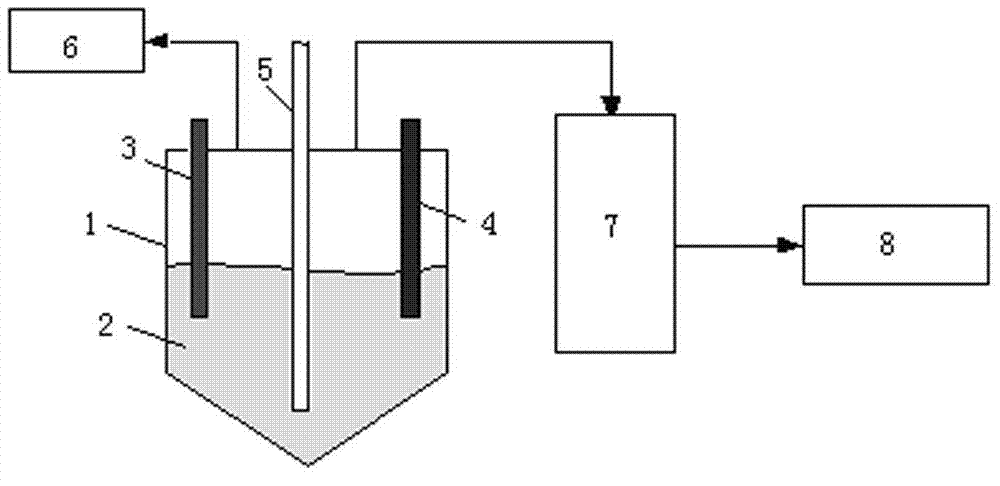

[0024] figure 1 It is a schematic diagram of a recovery system of vanadium-containing mud produced by removing vanadium from crude titanium tetrachloride according to an exemplary embodiment of the present invention. Such as figure 1 As shown, the recovery system includes molten salt furnace 1, gas supply pipe 5, TiCl 4 Gas collection unit 6, condenser 7 and VOCl 3 Product storage unit 8 .

[0025] Among them, molten salt furnace 1 can make crude TiCl 4 Heating to 600-750°C, it includes a furnace body with an inner cavity, a vanadium-containing mud inlet arranged on the furnace body, an exhaust port arranged on the top of the furnace body, and molten salt 2 contained in the inner cavity (Also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com