Method for treating waste water through coal pyrolysis and dry distillation

A waste water treatment and coal pyrolysis technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve flocculation and sedimentation, unable to reach suspended ash, difficult to remove, etc. Problems, to achieve the effect of huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

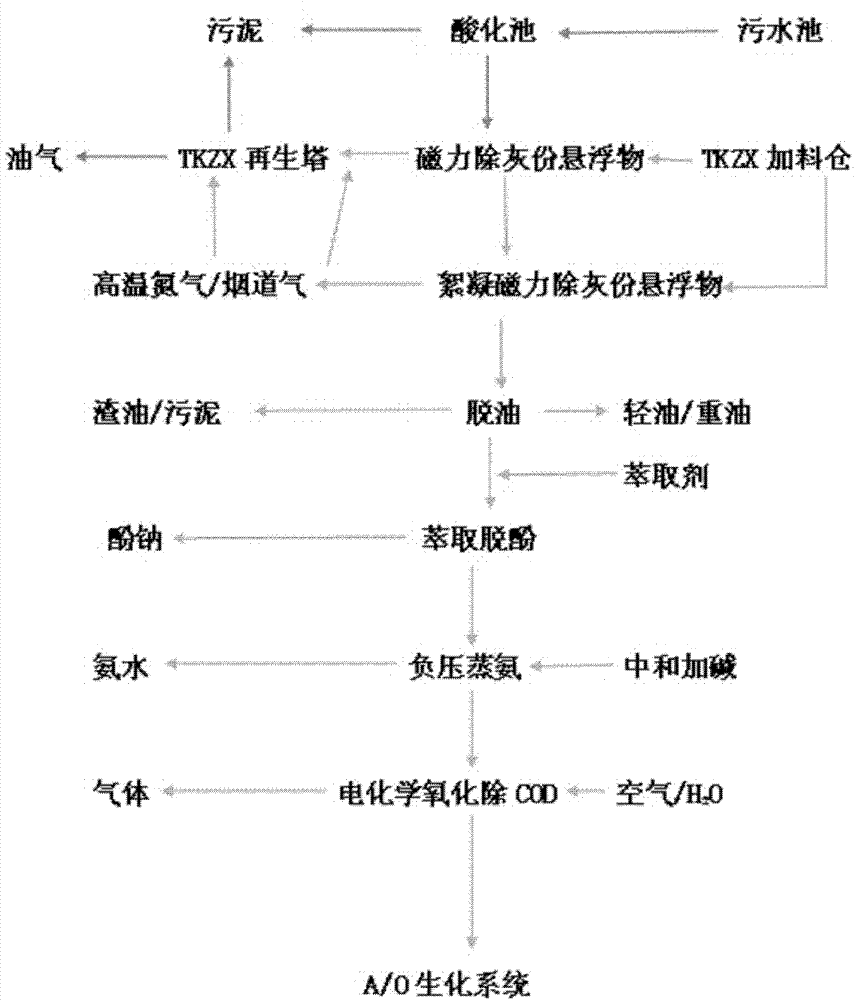

Image

Examples

Embodiment Construction

[0019] The present invention adopts magnetic material as the magnetic material adsorbent for suspended matter of ash, and the magnetic material is an oxidized organic polymer modified iron-based microporous material, which has a strong ability to adsorb and gather suspended matter in waste water. The material is put into the wastewater, stirred slowly, and then the mixture of the material and the wastewater is passed through a high-intensity magnetic field. After the magnetic field absorbs the material, the material with ash suspended matter is separated from the wastewater to achieve the purpose of removing the ash in the wastewater.

[0020] The process scheme provided by the present invention has a removal rate of ash suspended matter of more than 90%. The magnetic material adsorbent can be regenerated and reused, the loss rate is ≤2.4%, and the magnetic material adsorbent required per cubic meter of wastewater is 0.3 cubic meters.

[0021] Because the main material is Fe ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap