Method for producing urea formaldehyde controlled-release compound fertilizer

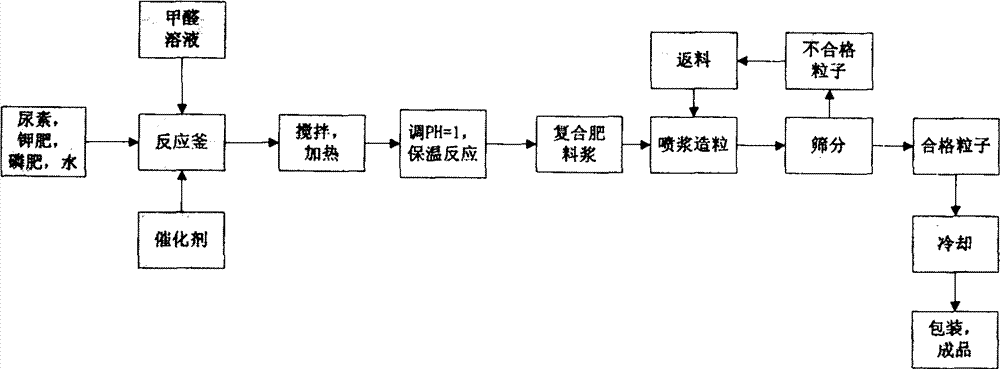

A production method and urea-formaldehyde slow-release technology are applied in fertilization devices, fertilizer mixtures, applications and other directions, can solve the problems of high production cost and complex production process, and achieve the effects of low production cost, short process flow, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] Add 358kg of urea, 1800kg of water, 200kg of potassium chloride and 136kg of monoammonium phosphate into the reactor, stir at room temperature to dissolve it to obtain a mixed solution, the stirring speed is 350r / min, and then add 305kg of the mass concentration to 36% to 38%. Add the formaldehyde solution into the reaction kettle, add 1kg of catalyst, stir, raise the temperature to 30°C, adjust the pH value of the solution to 1 with phosphoric acid, and keep it warm for 40 minutes to obtain a compound fertilizer slurry, and pump the mixed slurry into the spraying machine Granulation in the granulation dryer. After the dried granular urea-formaldehyde compound fertilizer is screened and cooled, the unqualified particles with a particle size of less than 1 mm are directly returned to the granulator for granulation, and the particles larger than 4 mm are crushed and returned to granulation. Re-granulate in the machine, and the qualified particles are packaged into finished...

example 2

[0021] Add 272 g of urea, 2000 kg of water, 200 kg of potassium sulfate, 227 kg of monoammonium phosphate, 2 kg of copper sulfate pentahydrate, 4 kg of zinc sulfate heptahydrate, 2 kg of magnesium sulfate heptahydrate and 2 kg of borax into the reaction kettle, stir to dissolve at room temperature to obtain a mixed solution , the stirring speed is 400r / min, and then 288kg of formaldehyde solution with a mass concentration of 36% to 38% is added to the reaction kettle, 3kg of catalyst is added, stirred, the temperature is raised to 45°C, the pH value of the solution is adjusted to 2.5 with sulfuric acid, and the temperature is kept React for 2 hours to obtain compound fertilizer slurry, and pump the mixed slurry into the spray granulation dryer for granulation. After the dried granular urea-formaldehyde compound fertilizer is screened and cooled, unqualified particles with a particle size of less than 1 mm Directly return to the granulator for granulation. The particles larger t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com