Nanometer water-saving pipe, water-saving device and manufacturing methods of two

A technology of water-saving devices and water-saving pipes, which is applied to botany equipment and methods, watering devices, tubular objects, etc., can solve problems such as difficult quality assurance, unhelpful plant growth, and complicated construction of infiltration irrigation technology, so as to increase production and quality, avoiding breeding, and solving irrigation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

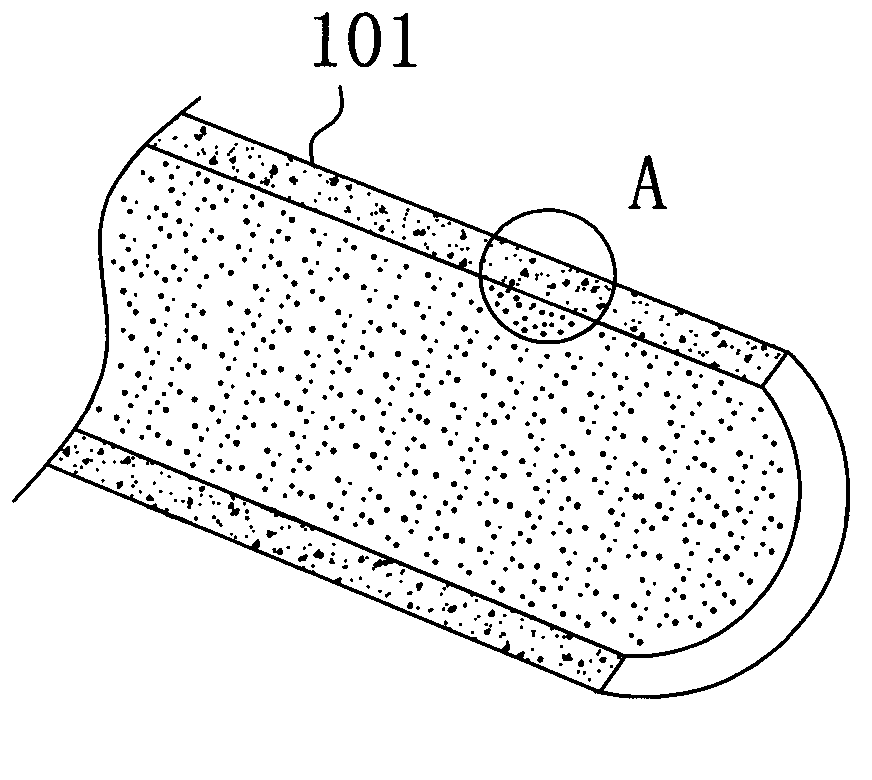

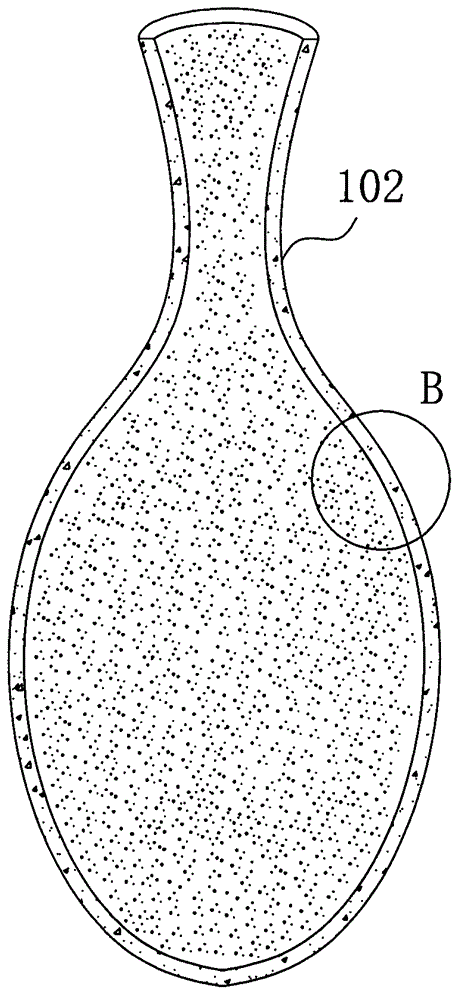

[0032] refer to Figure 1 to Figure 2 As shown, the embodiment of the present invention provides a nano-water-saving pipe. The nano-water-saving pipe 101 is made of modified plastic particles at least extruded through an extruder, and then heated and inflated to expand. The pipe wall is formed with nano-scale Water seepage hole 1011; the weight ratio of the components included in the modified plastic particles is:

[0033] 40% to 60% of polypropylene, 10% to 15% of nano calcium carbonate, 12% to 15% of white carbon black, 1% to 5% of water permeable agent, 5% to 15% of mica particles, 2% to 10% of antioxidant , light stabilizer 2%-5%, petroleum resin 2%-5%, the above components are mixed and granulated to form the modified plastic particles.

Embodiment 2

[0035] An embodiment of the present invention provides a method for manufacturing a nanometer water-saving pipe, which includes the following steps:

[0036] a. The weight ratio is 40% of polypropylene, 15% of nano-calcium carbonate, 15% of white carbon black, 5% of water-permeable agent, 15% of mica particles, 5% of antioxidant, 3% of light stabilizer, and 2% of petroleum resin. Mix and granulate to form modified plastic particles. Specifically, the above-mentioned various materials are put into a 200 kg high-speed mixer step by step according to the PP modified material granulation production process, and a certain temperature is given at the same time to ensure the granulation of various materials. Stir evenly to form a mixed material, then add the evenly stirred mixed material to a 70-type plastic twin-screw granulator for granulation. The above processing technology obtains modified plastic particles.

[0037] b. The modified plastic particles are added to a PP single-s...

Embodiment 3

[0042] A kind of manufacture method of nanometer water-saving pipe, it comprises the following steps:

[0043] a. The weight ratio is 60% of polypropylene, 10% of nano-calcium carbonate, 12% of white carbon black, 1% of water-permeable agent, 5% of mica particles, 2% of antioxidant, 5% of light stabilizer, and 5% of petroleum resin. Mix and granulate to form modified plastic particles. Specifically, the above-mentioned various materials are put into the 250-type high-speed mixer step by step according to the PP modified material granulation production process, and a certain temperature is given at the same time to ensure the mixing of various materials. Evenly, then add the evenly stirred material to the 75-type plastic twin-screw granulator for granulation. The working temperature of the plastic twin-screw granulator is about 200-230°C, and the cooling method is water cooling and air cooling. It is obtained through the above processing technology Modified plastic particles. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com