Human Lactobacillus fermentum grx07 and its application

A technology of Lactobacillus fermentum and fermented milk products, applied in fermented dairy products and functional foods or medicines, in the field of human Lactobacillus fermentum, to achieve the effects of reducing blood lipids, enhancing expression, and reducing the percentage of liver cell apoptosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

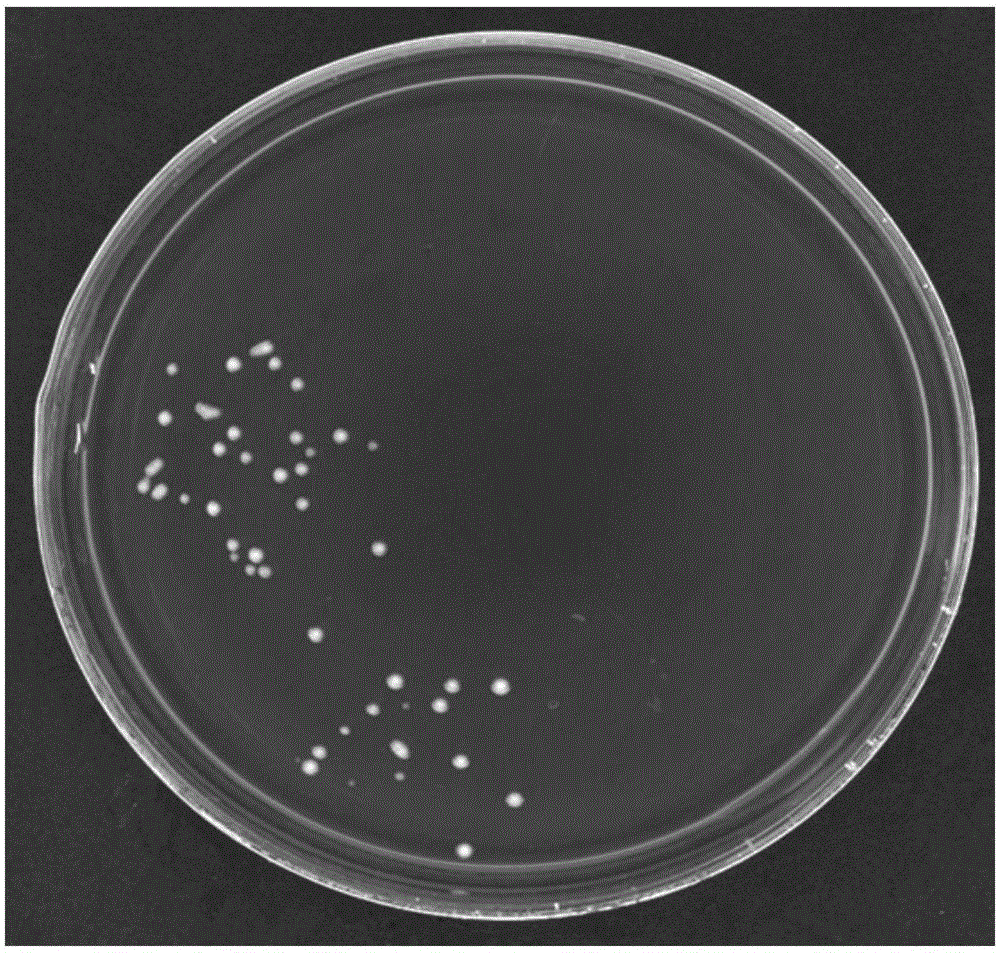

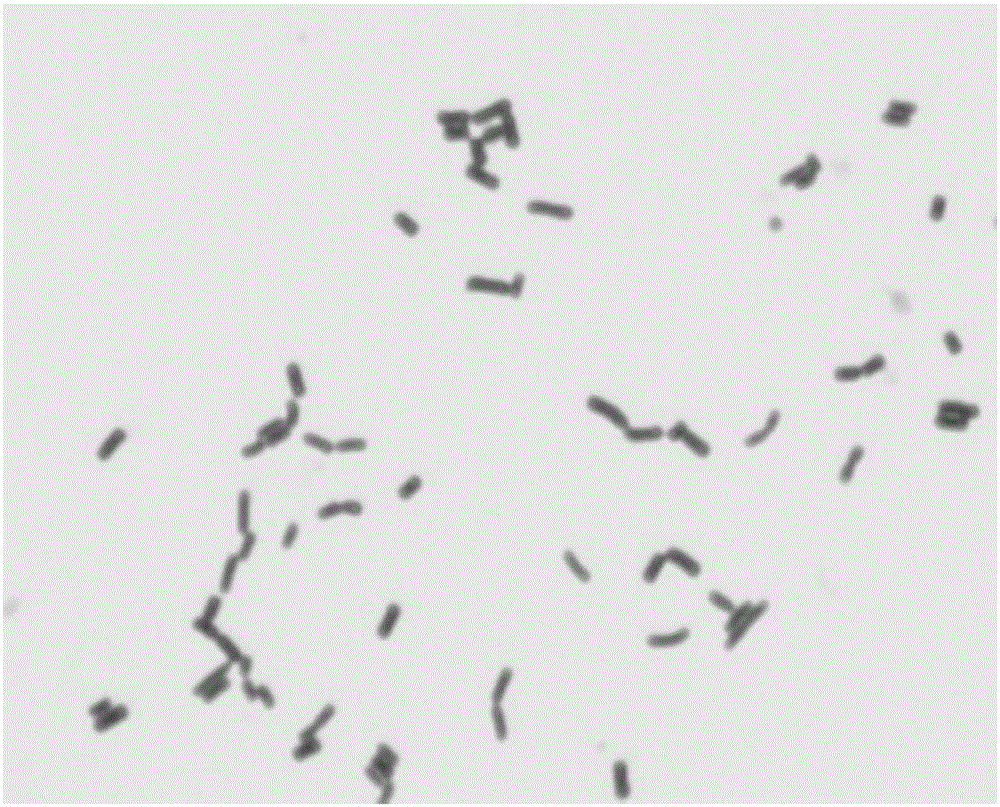

[0172] Embodiment 1: the preparation of Lactobacillus fermentum grx07 starter

[0173] The original strain of Lactobacillus fermentum grx07 was inoculated in 12% skim milk (sterilized at 115°C for 20 minutes), cultured at 37°C for 18-24 hours until the curdled milk was activated for two generations, and used as a mother starter. Inoculate the mother starter into 12% skim milk (sterilized at 115°C for 20 minutes) at an inoculum amount of 3% to 5%, and incubate at 37°C for 18 to 24 hours until the curdled milk, at which time the number of viable bacteria can reach 10 9 ~10 10 cfu / mL to obtain Lactobacillus fermentum grx07 starter.

Embodiment 2

[0174] Example 2: Preparation of functional fermented milk using Lactobacillus fermentum grx07

[0175]Heat the pretreated milk to about 60°C, add 6% sucrose, fully dissolve, and homogenize under 20MPa pressure. After heat treatment at 95°C / 5min, cool to 38°C. Add the Lactobacillus fermentum grx07 starter prepared according to Example 1 according to the inoculum amount of 5%, ferment at 37°C for 14-18h to curd milk, and then refrigerate at 4°C after cooling to obtain Lactobacillus fermentum grx07 functional fermented milk.

Embodiment 3

[0176] Embodiment 3: Utilize Lactobacillus fermentum grx07 to prepare probiotic milk beverage

[0177] The skim milk powder is made into 350kg of 12% reconstituted skim milk, heat-treated at 95°C / 8-10min, and then cooled to 37-40°C. Inoculate Lactobacillus fermentum grx07 starter with 3%~5% inoculum amount, culture at 37°C for 20~24h, and control the terminal acidity at 155~170°T; add 650kg of sugar sterilized at 90~110°C / 5~10s, stabilize (the composition of the mixture is 0.9%~1.4% pectin and 13.8%~15.4% sucrose), after mixing evenly, it is homogeneous at 20~25MPa, then heat treatment at 72℃ / 15s, and cool to 15~ 20°C, adopt aseptic or hygienic filling to obtain 1000kg of Lactobacillus fermentum grx07 milk beverage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com