SERS (Surface Enhanced Raman Scattering) substrate with self-assembled spherical array and preparation method thereof

A self-assembly and substrate technology, applied in the fields of biosensors and chemical analysis and detection, can solve the problems of cumbersome process and high cost, and achieve the effect of simplifying the process flow, saving costs, and having low equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

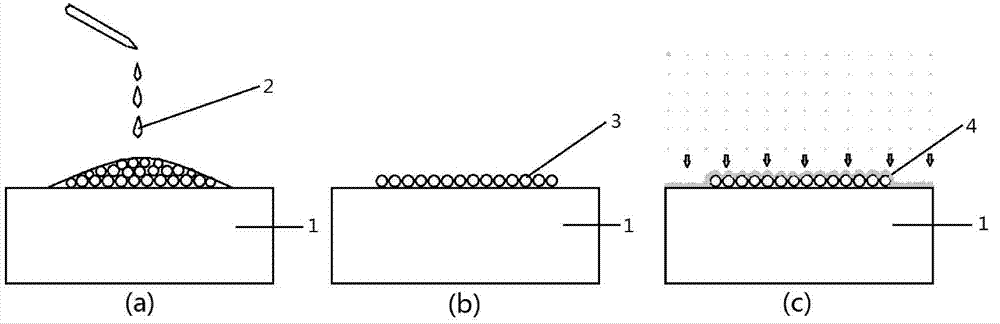

Method used

Image

Examples

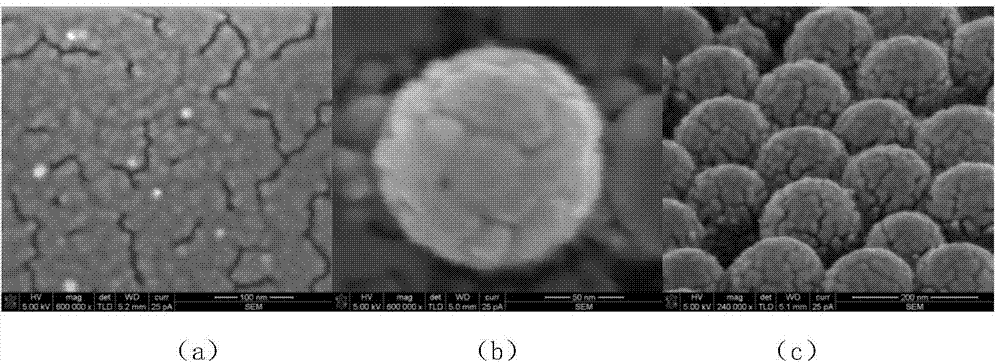

Embodiment 1

[0036] Put the flat Si substrate into the prepared piranha lotion, take it out after ultrasonic treatment for 30 minutes, and rinse it with a large amount of deionized water. Afterwards, immerse the substrate in the mixed solution of ammonia water and hydrogen peroxide and continue ultrasonication for 40 minutes. After completion, take it out, wash it with a large amount of deionized water, and place it in the air to dry naturally. Microsphere solution, prepared as a solution with a concentration of w / v=0.5%, put it into an ultrasonic machine for 40 minutes and took it out; pipette 2ul polystyrene solution with a micropipette and drop it on the hydrophilic treated Si substrate On-chip, control the ambient temperature so that it can successfully complete independent self-assembly; the substrate after self-assembly is placed in an ion coating instrument, and the vacuum degree is controlled to 2×10 -2mbar, the ion current intensity is 10mA, and the evaporation time is selected as...

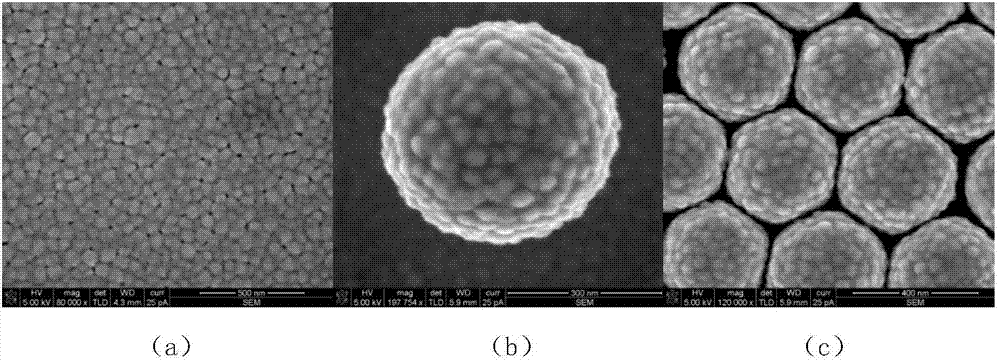

Embodiment 2

[0038] Put the flat Si substrate into the prepared piranha lotion, take it out after ultrasonic treatment for 30 minutes, and rinse it with a large amount of deionized water. Afterwards, immerse the substrate in the mixed solution of ammonia water and hydrogen peroxide and continue ultrasonication for 40 minutes. After completion, take it out, wash it with a large amount of deionized water, and place it in the air to dry naturally. Microsphere solution, prepared as a solution with a concentration of w / v=0.18%, placed in an ultrasonic machine for 50 minutes and then taken out; pipette 2ul polystyrene solution with a micropipette and drop it on the Si substrate treated with hydrophilic , control the temperature of the surrounding environment so that it can successfully complete independent self-assembly; the substrate after self-assembly is placed in an ion coating instrument, and the vacuum degree is controlled to be 2×10 -2 mbar, the ion current intensity is 10mA, and the evap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com