Manufacturing method for high-voltage self-recovery fuse wire

A self-restoring fuse and manufacturing method technology, applied in the direction of fuse manufacturing, etc., can solve the problems of low gel content, long time required, inevitable oxidation reaction, etc., and achieve the effect of high utilization rate of radiation energy and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

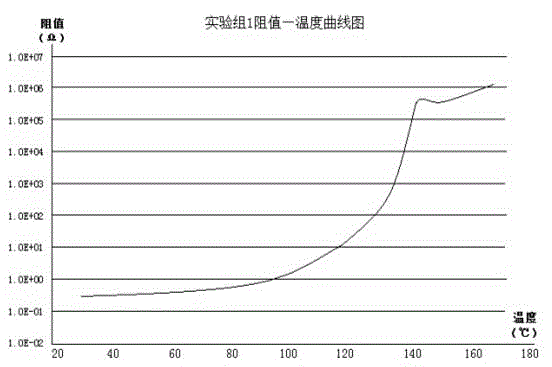

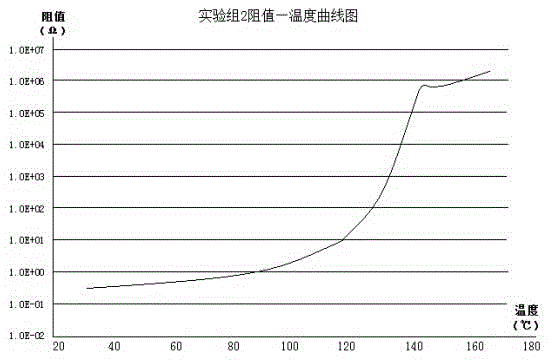

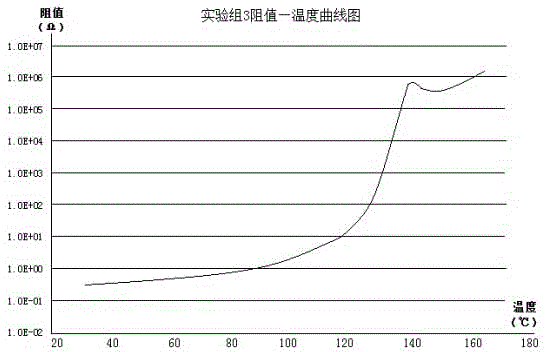

[0015] A method for manufacturing a high-voltage resettable fuse. The positive temperature coefficient polymer composite material formed by polyethylene and carbon black pellets is placed on a conveyor belt and passes through an electron accelerator. The total radiation dose generated by the electron accelerator is 900-1100KGY, and the radiation energy is 2.7-3.2 Mev, beam current 8.9-10.1mA electron beam for radiation, the positive temperature coefficient polymer composite material passes through the electron beam at a speed of 14.5-15.5 meters per minute, and the total number of laps passed is 95-105 laps.

[0016] PTC, positive temperature coefficient polymer composite material, referred to as polymer, is a resettable fuse, which is composed of specially treated polymer resin and conductive particles distributed inside. It has a unique positive temperature coefficient resistance characteristic, that is, within a certain temperature range, its own resistance will increase as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com