Enzyme process yellow ensilage method of corn straws

A corn stalk and enzymatic technology, which is applied in the field of yellow storage technology, can solve the problems of strong seasonality, low feed energy, easy production of aflatoxin, etc., and achieves the effect of saving cost and improving the effect of yellow storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

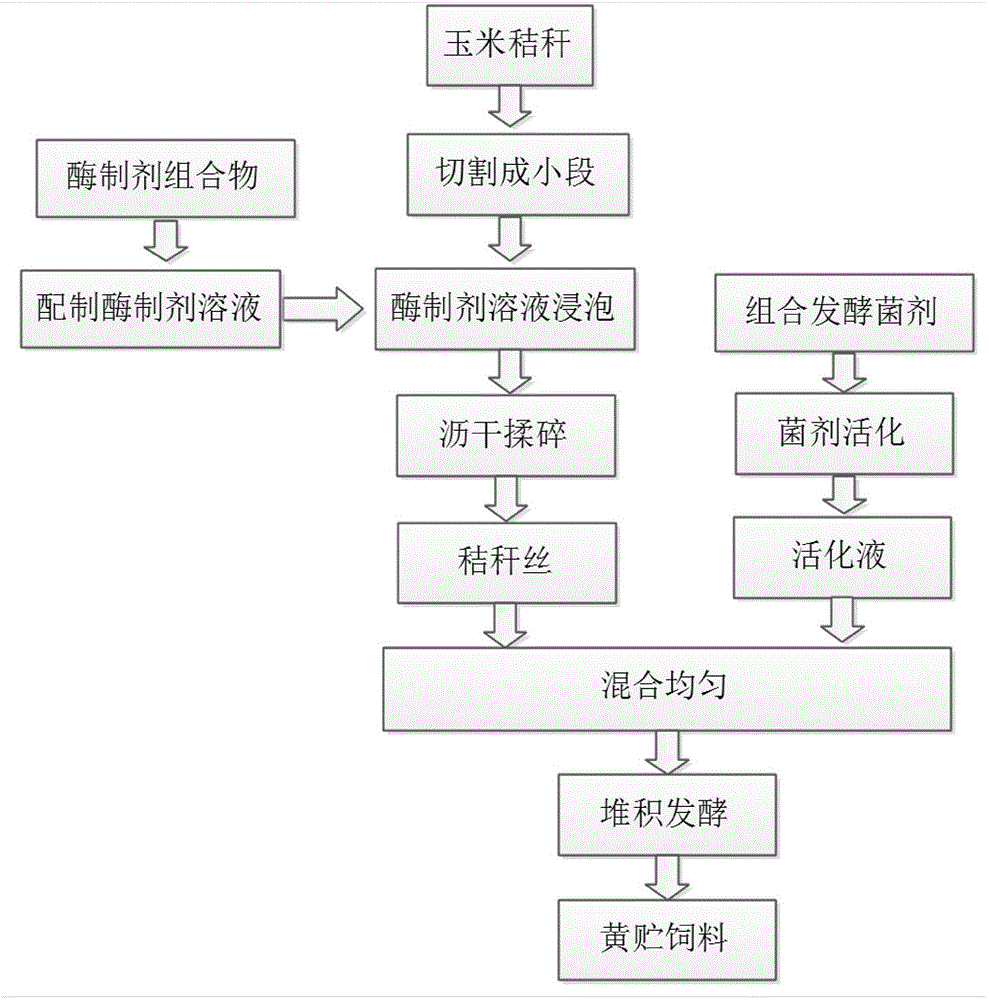

Method used

Image

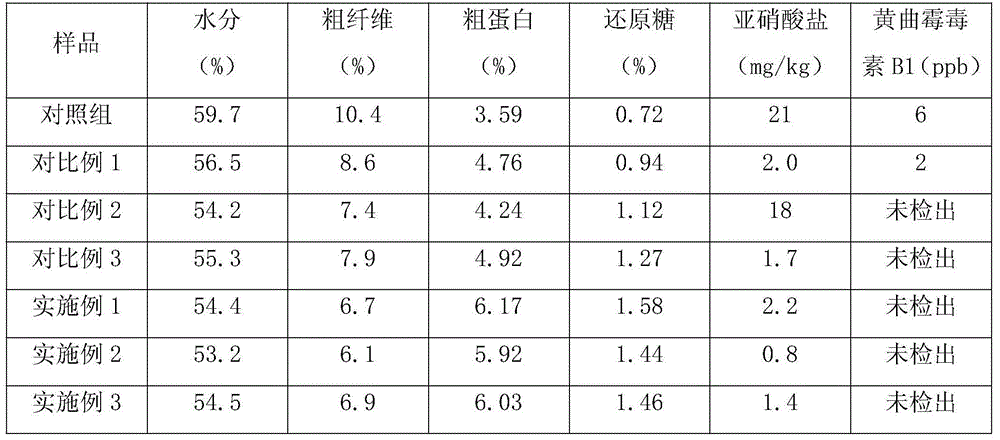

Examples

Embodiment 1

[0044] A method for enzymatic yellow storage of corn stalks, comprising the following steps:

[0045] (1) Activate the combined fermentation agent in the activation solution at 35°C for 1 hour. The fermentation agent is composed of the following components in mass percentage: Saccharomyces cerevisiae 40%, Aspergillus oryzae 15%, Aspergillus niger 20%, Bacillus subtilis 15%, denitrifying bacteria 10%, described activation solution is made up of each component of following mass percentage: sucrose 7%, urea 3%, potassium dihydrogen phosphate 4%, corn flour 3%, water 83%, the activation solution The quality is 20 times that of the fermenting agent;

[0046] (2) Dilute the enzyme preparation composition with 12 times its mass of water to make an enzyme preparation solution. The enzyme preparation composition is composed of the following components in mass percentage: cellulase 45%, xylanase 30% %, phytase 15%, aflatoxin B1 decomposing enzyme 6%, auxiliary agent 4%, said auxiliary ...

Embodiment 2

[0053] A method for enzymatic yellow storage of corn stalks, comprising the following steps:

[0054] (1) Activate the combined fermentation agent in the activation solution at 20°C for 3 hours. The fermentation agent is composed of the following components in mass percentage: Saccharomyces cerevisiae 30%, Aspergillus oryzae 25%, Aspergillus niger 15%, Bacillus subtilis 20%, denitrifying bacteria 10%, described activation solution is made up of each component of following mass percentage: sucrose 8%, urea 3%, potassium dihydrogen phosphate 5%, corn flour 2%, water 82%, the activation solution The quality is 25 times that of the fermenting agent;

[0055] (2) Dilute the enzyme preparation composition with 15 times its mass of water to prepare an enzyme preparation solution. The enzyme preparation composition is composed of the following components in mass percentage: cellulase 40%, xylanase 40% %, phytase 10%, aflatoxin B1 decomposing enzyme 5%, auxiliary agent 5%, said auxili...

Embodiment 3

[0062] A method for enzymatic yellow storage of corn stalks, comprising the following steps:

[0063] (1) Activate the combined fermentation agent in the activation solution at 28°C for 2 hours. The fermentation agent is composed of the following components in mass percentage: Saccharomyces cerevisiae 35%, Aspergillus oryzae 20%, Aspergillus niger 20%, Bacillus subtilis 15%, denitrifying bacteria 10%, described activation solution is made up of each component of following mass percentage: sucrose 6%, urea 4%, potassium dihydrogen phosphate 3%, corn flour 2, water 85%, the quality of activation solution 24 times the quality of the fermentation agent;

[0064] (2) Dilute the enzyme preparation composition with 12 times its mass of water to prepare an enzyme preparation solution. The enzyme preparation composition is composed of the following components in mass percentage: cellulase 45%, xylanase 35% %, phytase 10%, aflatoxin B1 decomposing enzyme 5%, auxiliary agent 3%, said au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com