Peony seed oil microcapsules as well as preparation method and application thereof

A technology of peony seed oil and microcapsules, which is applied in the field of peony seed oil microcapsules and its preparation, can solve the problems of microcapsule preparation cost reduction, high cost, poor fluidity and compactness, etc. Large, low volatility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

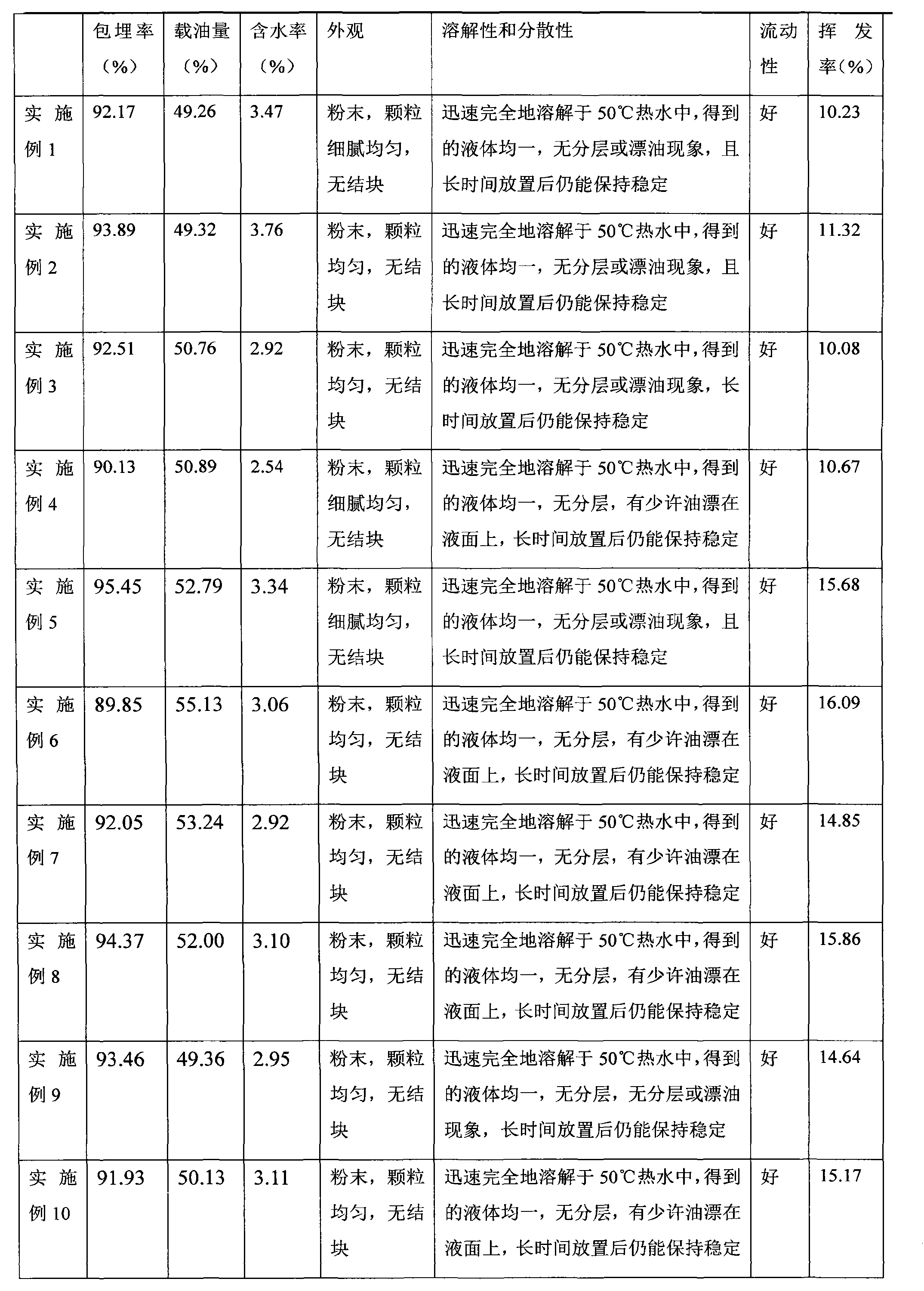

Examples

Embodiment 1

[0039] Example 1 Yeast wall material prepares peony seed oil microcapsules

[0040] Step 1 Purification of spent yeast liquid

[0041] Take the waste yeast liquid from brewing or antibiotic factory, wash it with 2 times the volume of sterile water, sieve it twice with 80-mesh and 100-mesh sieves to remove hop resin and other large impurities, centrifuge at 3000r / min for 10min at room temperature, Discard the supernatant, and then wash with sterile water for 1-2 times until the supernatant is colorless and odorless, centrifuge to obtain milky white yeast milk, and vacuum dry or spray dry to obtain dry yeast granules.

[0042] Step 2 Yeast autolysis to prepare wall material

[0043] Take the purified yeast, add 4 times of water to make a suspension, then add 0.5% ethanol as an autolysis promoter, and adjust the initial pH value to 6, autolyze in the range of 40-60°C for 48 hours, at 80°C , inactivate the enzyme for 15 minutes, centrifuge at 3000 r / min for 40 minutes, and vacuu...

Embodiment 2

[0046] Example 2 Yeast wall material prepares peony seed oil microcapsules

[0047] Step 1 Dry Yeast Inactivation

[0048] Inactivate the food-grade dry yeast at 65°C for 30 minutes, or irradiate it with ultraviolet light.

[0049] Step 2 Yeast autolysis to prepare wall material

[0050] Take the inactivated dry yeast, add 6 times of water to make a suspension, then add the autolysis promoter 1% ethanol, and adjust the initial pH value to 5, autolyze at 40-60°C for 24 hours, at 95 Inactivate the enzyme for 10 minutes at ℃, centrifuge at 5000 r / min for 30 minutes, and vacuum-dry or freeze-dry at 30 ℃ to obtain the yeast cell wall for future use.

[0051] Preparation of Step 3 Peony Seed Oil Microcapsules

[0052] Take peony seed oil as the core material, and the treated yeast as the wall material, add peony seed oil and yeast in the ratio of 1:1 to the core material and wall material to seal, put it in a 70°C constant temperature water bath oscillator, and the oscillation fr...

Embodiment 3

[0053] Example 3 Yeast wall material prepares peony seed oil microcapsules

[0054] Step 1 Purification of spent yeast liquid

[0055] Take the waste yeast liquid from brewing or antibiotic factory, wash it with 3 times the volume of sterile water, sieve it twice with 80 mesh and 100 mesh sieves to remove hop resin and other large impurities, centrifuge at 5000r / min at room temperature for 5min, Discard the supernatant, and then wash with sterile water for 1-2 times until the supernatant is colorless and odorless, centrifuge to obtain milky white yeast milk, and vacuum dry or spray dry to obtain dry yeast granules.

[0056] Step 2 Yeast autolysis to prepare wall material

[0057] Take the purified yeast, add 8 times of water to make a suspension, then add autolysis promoter 3% ethanol, and adjust the initial pH value to 7, autolyze in the range of 40-60°C for 12 hours, at 85°C , inactivate the enzyme for 12 minutes, centrifuge at 4000 r / min for 35 minutes, and vacuum-dry or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com