Preparation method for low-dielectric-constant fine silicon powder

A low dielectric constant and dielectric constant technology, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of insufficient pressure resistance of powder, easy breakage, and poor electrical performance of downstream products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

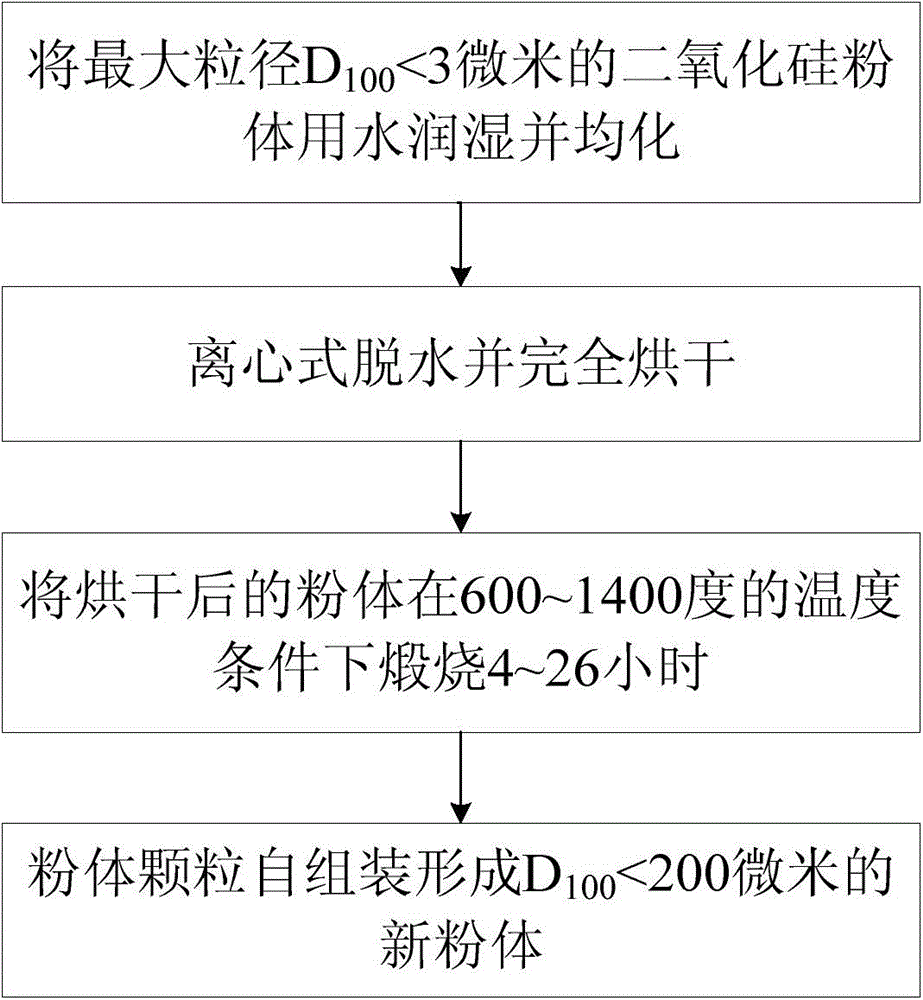

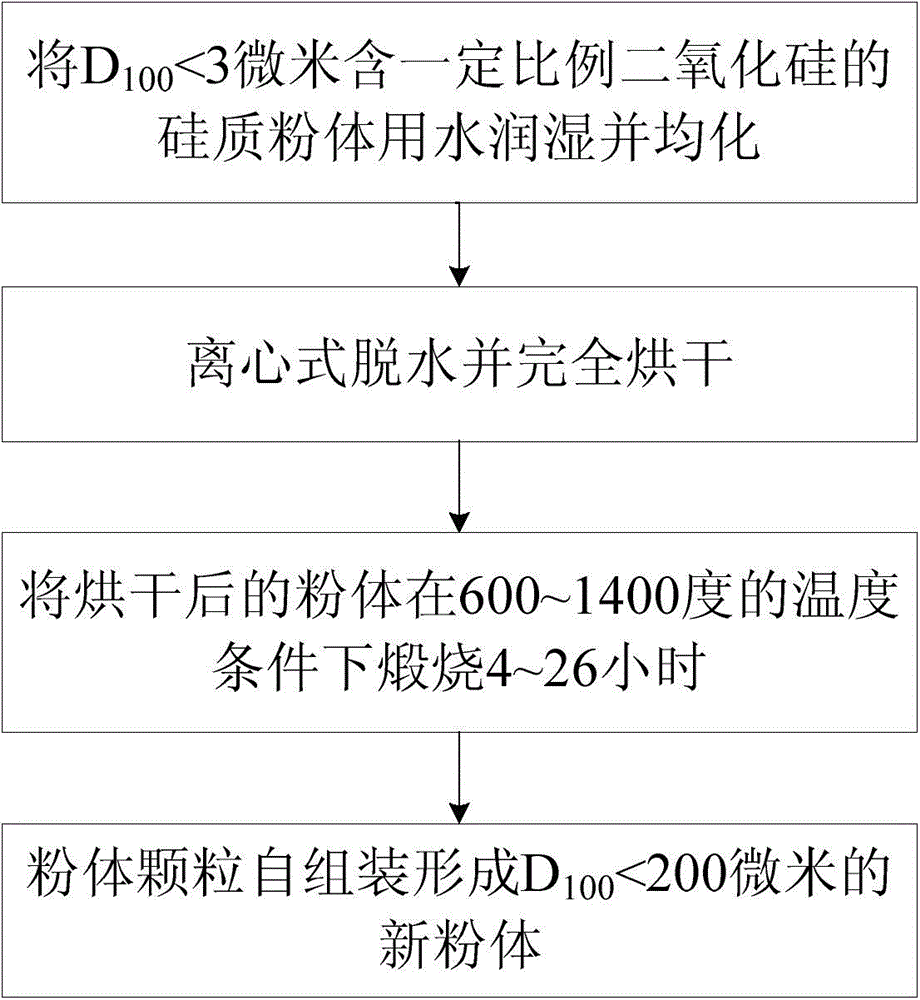

[0036] The specific steps of the preparation method of the present invention are as follows: the maximum particle diameter D 100 Spherical or angular (flaky) pure silica or silica powder with a certain proportion of 100 A new powder that is continuously adjustable below 5-200 microns. This powder has the advantages of light weight, self-assembly, low hardness and low dielectric constant. Its Moss hardness is between 2-3 and the dielectric constant is less than 3 (about 2.5), which significantly improves the hardness and processing performance of copper-clad aluminum laminates.

[0037] Among them, the maximum particle size D 100 Commercially available silicon dioxide or silicon dioxide containing a certain proportion of silicon dioxide <3 microns can be used.

[0038] The dehydration method adopts one selected from press filtration, centrifugation, sedimentation or heating. Among them, centrifugal dehydration is the best. While achieving solid-liquid separation, the gap betw...

Embodiment 1

[0043] The maximum particle size D 100 The silicon micropowder powder composed of 3 micron spherical silica is completely wetted with water with a weight ratio of 30%, and after homogenizing for several hours, it is centrifugally dehydrated in a centrifuge and kept at 140 degrees. 6 hours, and calcined at 600 degrees for 26 hours to form the largest particle size D 100 The new powder is continuously adjustable below 5-200 microns, wherein the dielectric constant of the new powder is about 2.5, which is more than 30% lower than that of the raw powder.

Embodiment 2

[0045] The maximum particle size D 100 The silicon micropowder powder composed of 0.4 micron spherical silica is completely wetted with water with a weight ratio of 40%, and homogenized for several hours, then centrifugally dehydrated in a centrifuge and kept at 140 degrees. 6 hours, and calcined at a temperature of 1250 degrees for 10 hours to form the largest particle size D 100 A new powder that is continuously adjustable below 5-200 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com