Printed circuit board scrap nonmetal powder baking-free brick and making method thereof

A non-metallic powder and waste printing technology, which is applied in the field of renewable resource recycling technology and building materials, can solve the problems of waste of land resources and energy consumption, and achieve the effects of environmental protection, no pollution, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

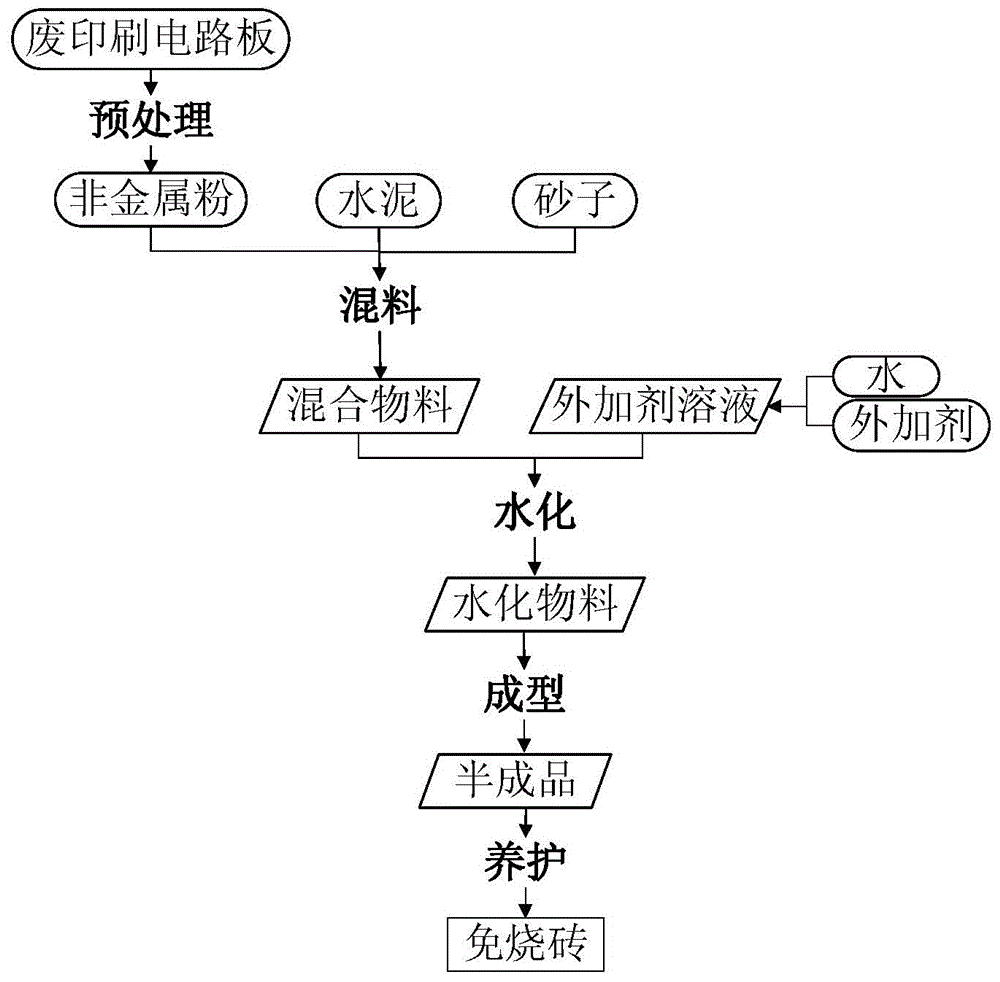

Method used

Image

Examples

Embodiment 1

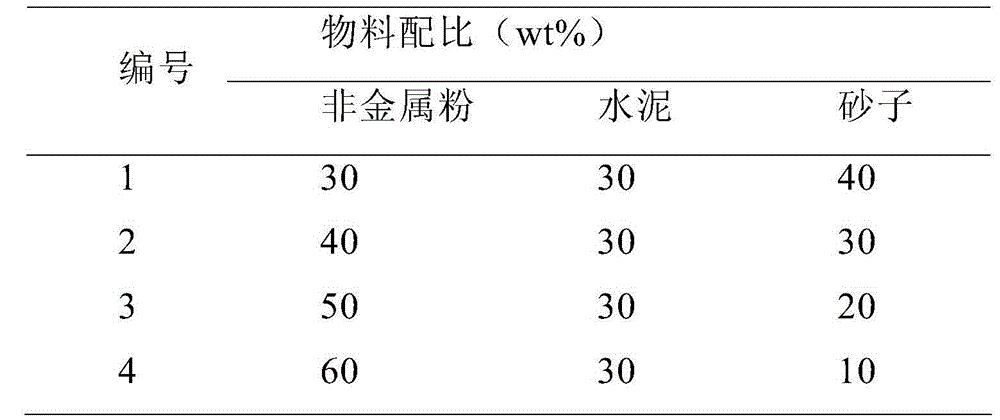

[0030] The types of raw materials and processing aids used in this embodiment and the implementation process are consistent with the above-mentioned five-step process. The difference is that there is no need to prepare an additive solution in step 3 of this embodiment, but directly add water to the mixed dry material at a weight ratio of 8% and stir evenly. In addition, the difference is that the material ratio of this embodiment is as follows:

[0031]

Embodiment 2

[0033] The raw materials used in this embodiment and the type of processing aid and the implementation process are consistent with the above-mentioned five-step process, the difference is that:

[0034] The proportioning of materials in the step 2 is non-metallic powder 30%wt, cement 20wt%, sand 40wt%, lime 5wt%, gypsum 5wt%;

[0035] In step 3, the admixture solution consists of 5wt% Na 2 SO 4 and 4wt% calcium lignosulfonate, and the admixture solution is added in the mixed material in a ratio of 10wt%;

[0036] The humidity in the curing environment for the first 7 days in step 5 is 80%, and the temperature is 25°C.

[0037] The compressive strength, flexural strength and other properties of the waste printed circuit board non-metal powder non-burning brick products prepared in the above examples are tested, and it is known that the prepared non-burning product has a compact structure and excellent performance, which meets the requirements of the national construction indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com