Semi-contact under-oil continuous droplet sample applying and liquid adding method

A semi-contact and droplet technology, which is applied to the analysis of materials and instruments, can solve problems such as cross-contamination and false-positive screening results, and achieve the effects of increasing speed, improving reliability and uniformity, and facilitating analysis and screening throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

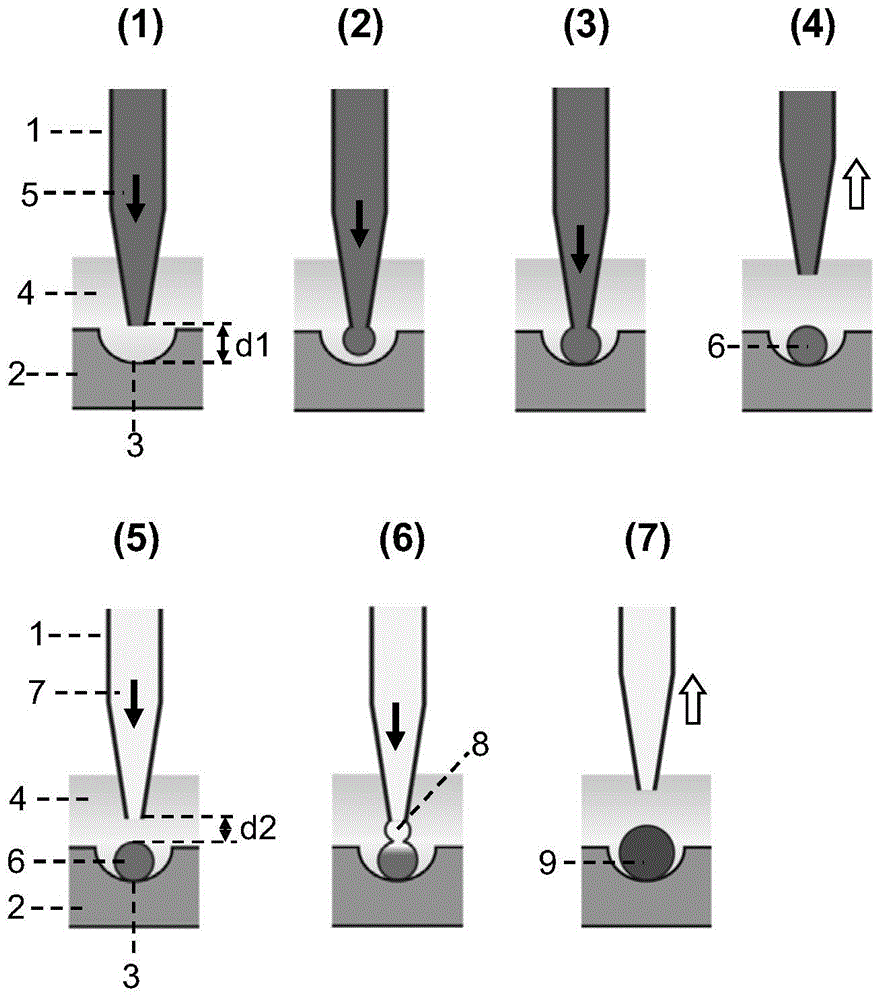

[0052] figure 1 It is a schematic diagram of the principle of using the semi-contact liquid droplet continuous spotting and liquid addition method to generate sample droplets and add reagents. The specific operation process of generating sample droplets 6 by continuous pointing of droplets ( figure 1 (1)-(4)) are as follows: the sampling end of capillary 1 is sharpened to reduce cross-contamination during sampling, and the inner wall of capillary 1 is treated with hydrophobic surface to prevent the adsorption of samples and reagents on its surface . A layer of oil phase 4 immiscible with water is covered on the microwell array chip 2 . Aspirate a certain volume of sample solution 5 to be sampled into the capillary 1 , and move the translation stage so that the capillary 1 is placed directly above the center of the microwell 3 of the microwell array chip 2 . According to the volume of the sample droplet, the distance d1 between the tip of the capillary 1 and the lower surfac...

Embodiment 2

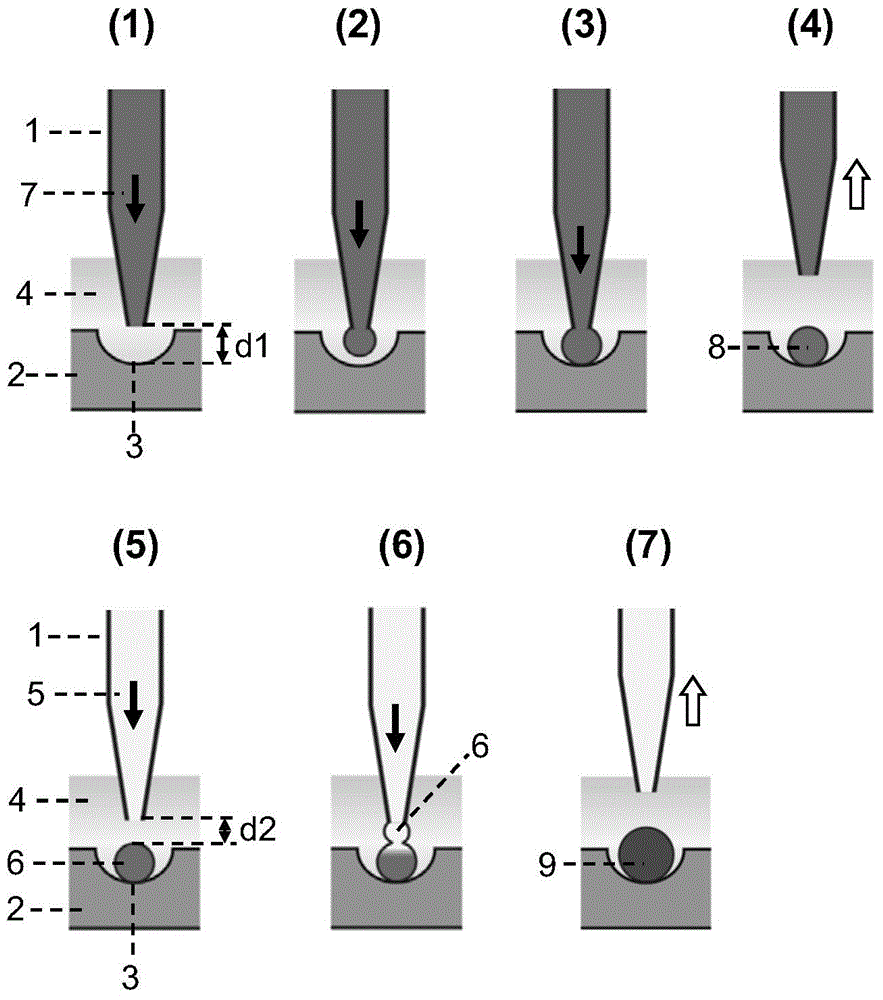

[0055] figure 2 It is a schematic diagram of the principle of the reagent droplet generation and sample addition operation using the semi-contact liquid droplet continuous pointing and liquid addition method. The specific operation process of generating reagent droplets 8 by continuous pointing of droplets ( figure 2 (1)-(4)) are as follows: the sampling end of capillary 1 is sharpened to reduce cross-contamination during sampling, and the inner wall of capillary 1 is treated with hydrophobic surface to prevent the adsorption of samples and reagents on its surface . A layer of oil phase 4 immiscible with water is covered on the microwell array chip 2 . Aspirate a certain volume of reagent solution 7 to be sampled into the capillary 1 , and move the translation stage so that the capillary 1 is placed directly above the center of the microwell 3 of the microwell array chip 2 . According to the volume of the spotting liquid droplet, the distance d1 between the tip of the cap...

Embodiment 3

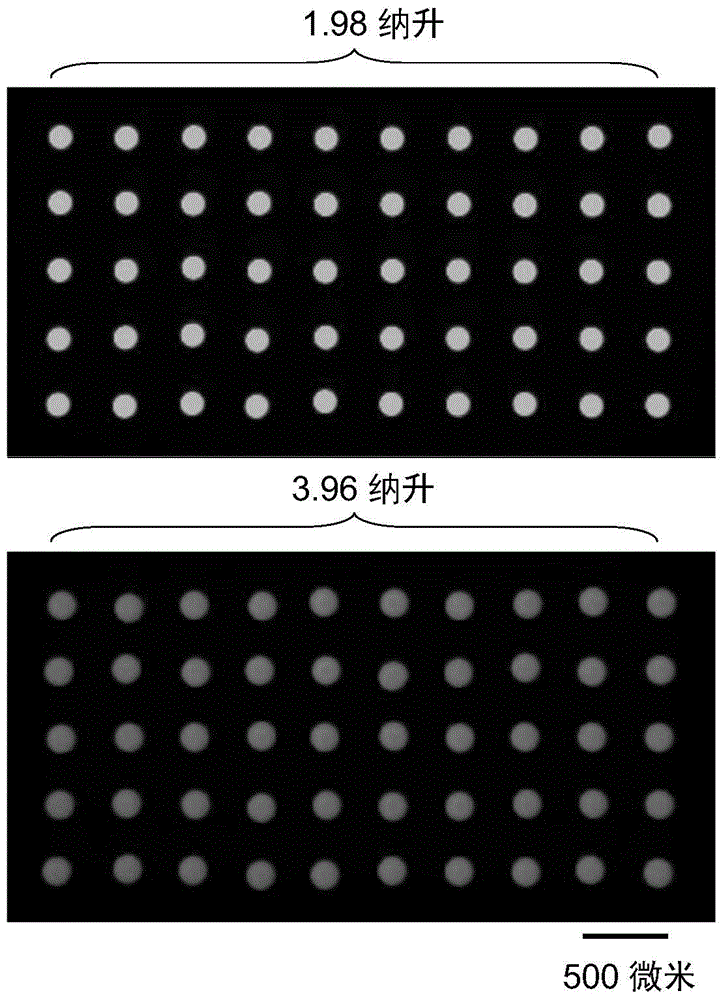

[0058] image 3 The picture of the fluorescein droplet array generated by the continuous droplet spotting method, and the picture of the droplet array obtained by diluting the fluorescein droplet array with equal volume by the continuous liquid addition method. In the experiment, the inner diameter of the capillary is 150 microns, and the outer diameter is 200 microns. The sampling end is sharpened, and the size of the tip is about 30 microns. The inner wall and tip of the capillary were hydrophobized with octadecyltrichlorosilane. Use a syringe pump equipped with a 1 microliter syringe as the liquid drive system, and connect the syringe to the capillary. The microhole array is processed on the glass substrate by photolithography and wet etching, the size of each microhole is 260 microns in diameter, 60 microns in depth, and the distance between the centers of the microholes is 400 microns. Octadecyltrichlorosilane was also used to treat the surface of the microwell array c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com