Preparation method of nano-fibrous lithium cobalt phosphate positive electrode material

A lithium cobalt phosphate, cathode material technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as poor electronic conductivity and harsh synthesis conditions, and achieve improved conductivity and preparation technology. Simple and controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of a nanofibrous lithium cobalt phosphate positive electrode material, the specific steps are:

[0024] 1) First, dissolve 8mmol of lithium hydroxide and phosphoric acid in 12ml of deionized water to generate a lithium dihydrogen phosphate solution, then add 1g of polyvinylpyrrolidone (molecular weight: 1.3 million) and stir well, then let the solution stand until it becomes clear;

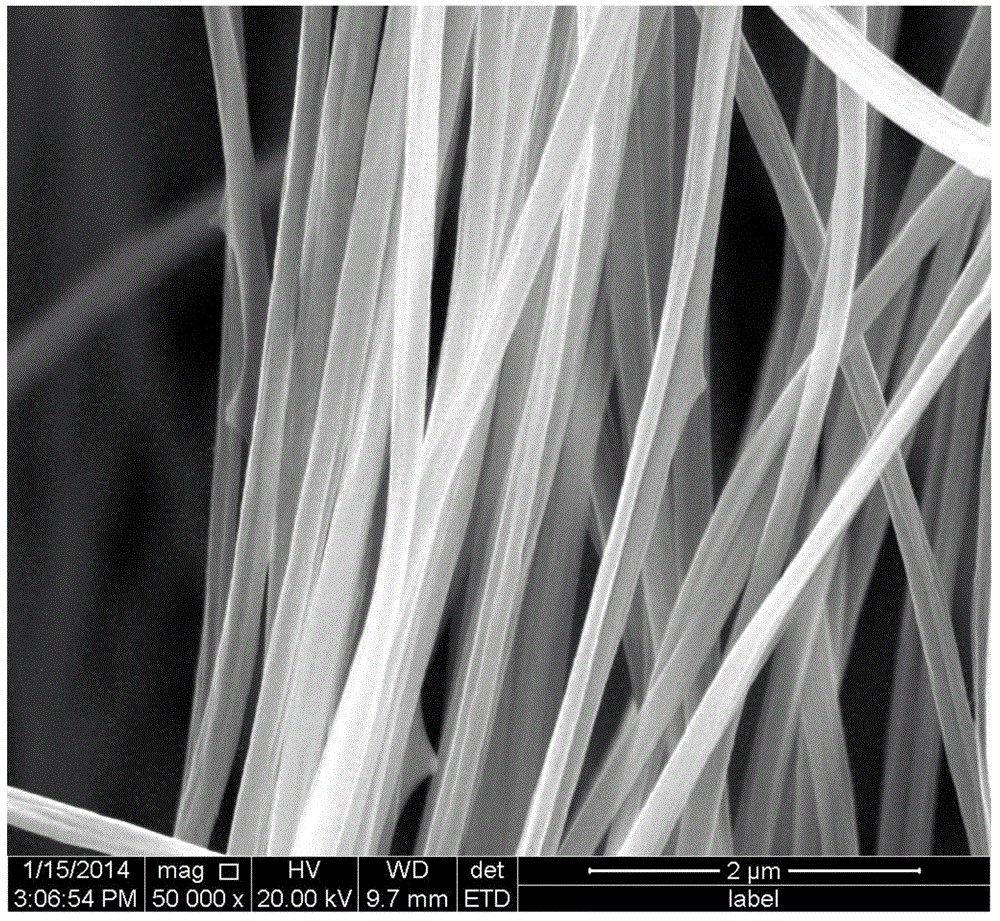

[0025] 2) Electrospin the obtained product, the positive high voltage is 30kv, the receiving end uses aluminum foil, and the negative high voltage is -5kv. The scanning electron microscope morphology of the collected spinning products is as follows: figure 1 shown.

[0026] 3) Calcinate the above spinning product in an argon atmosphere, the calcination temperature is 750°C, the heating rate is 5°C / min, and the reaction time is 12h; after the reaction is completed, the temperature of the material is cooled to room temperature, and the product is taken out to obtain nano...

Embodiment 2

[0030] 1) First, dissolve 12mmol of lithium dihydrogen phosphate and cobalt nitrate in 10ml of deionized water, then add 600mg of polyvinylpyrrolidone (molecular weight: 1.3 million) and stir well, then let the solution stand until it becomes clear;

[0031] 2) Electrospin the obtained solution, the positive high voltage is 10kv, the receiving end uses aluminum foil, and the negative high voltage is -10kv.

[0032] 3) Calcinate the above spinning product in an argon atmosphere, the calcination temperature is 650°C, the heating rate is 2°C / min, and the reaction time is 6h; after the reaction is completed, the temperature of the material is cooled to room temperature, and the product is taken out to obtain nanofibers with Morphology of lithium cobalt phosphate cathode material, and its electrochemical test.

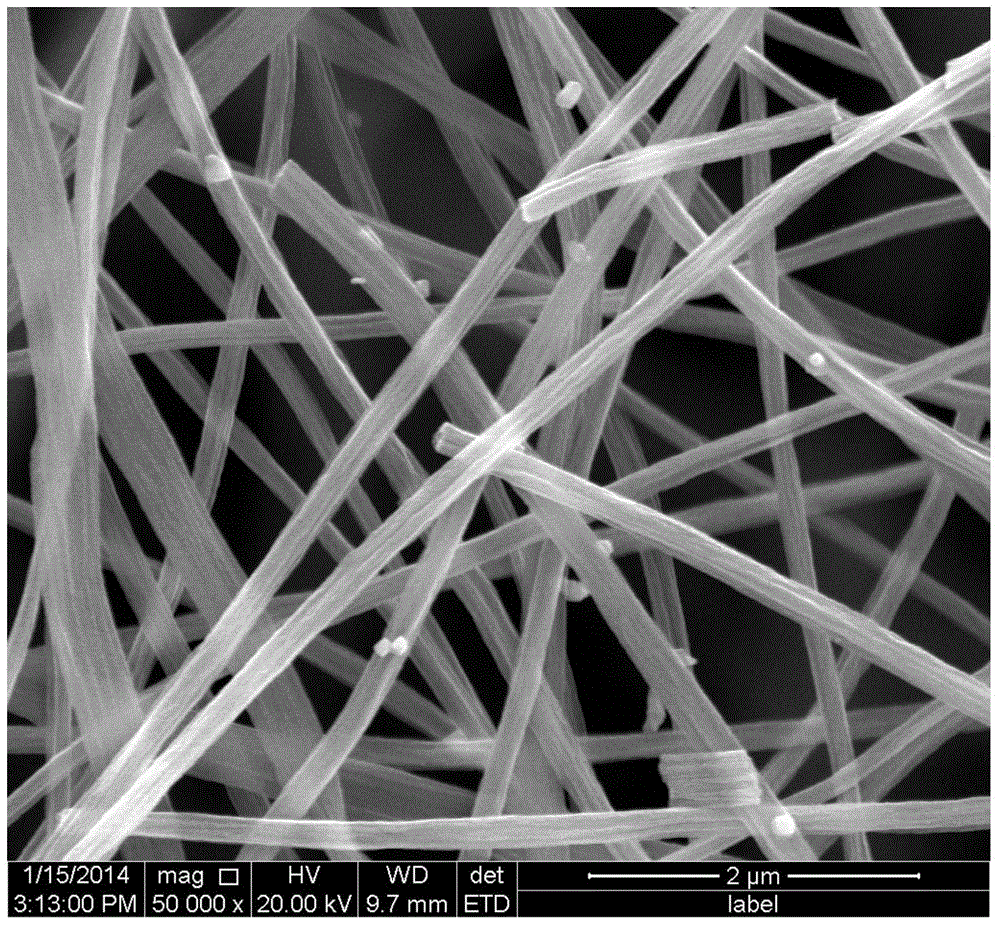

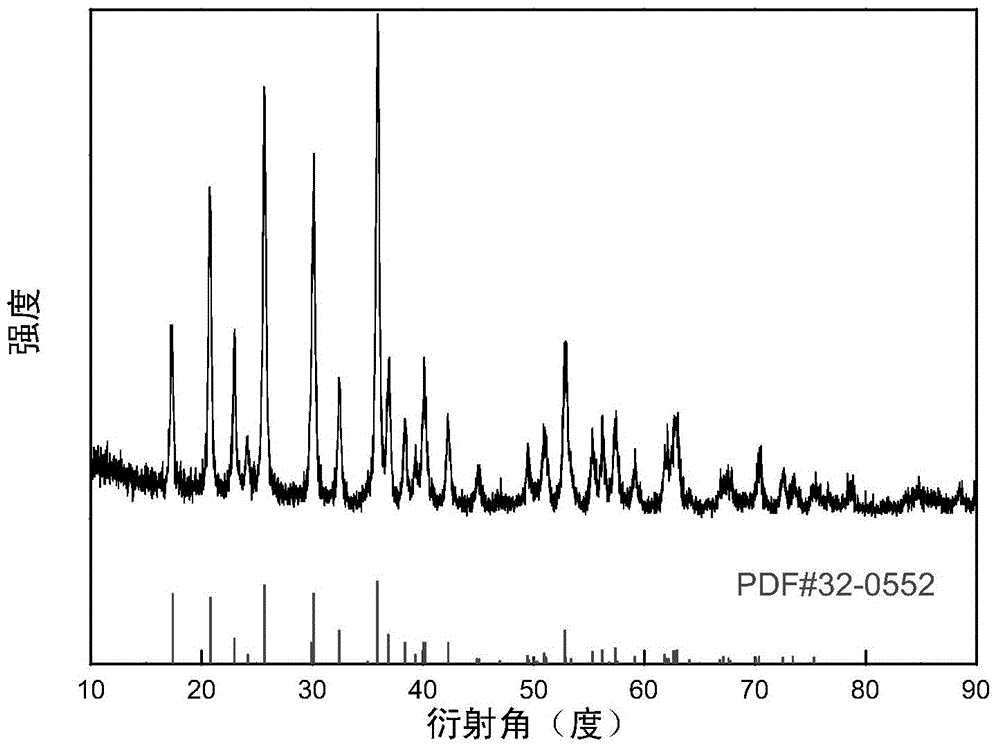

[0033] The obtained lithium cobalt phosphate positive electrode material is subjected to X-ray diffraction test, and the obtained diffraction pattern is compared with the s...

Embodiment 3

[0036] 1) First, dissolve 6mmol of lithium dihydrogen phosphate and cobalt nitrate in 10ml of deionized water, then add 800mg of polyvinyl alcohol and stir until dissolved, then let the solution stand until it becomes clear;

[0037] 2) The obtained solution is subjected to electrospinning, the positive high voltage is 15kv, the receiving end is made of aluminum foil, and the negative high voltage is 0kv.

[0038] 3) Calcinate the above spinning product under a nitrogen atmosphere, the calcination temperature is 700°C, the heating rate is 2°C / min, and the reaction time is 8h; after the reaction is completed, the material temperature is cooled to room temperature, and the product is taken out to obtain a The appearance of lithium cobalt phosphate cathode material, and its electrochemical test.

[0039] The obtained lithium cobalt phosphate positive electrode material is subjected to X-ray diffraction test, and the obtained diffraction pattern is compared with the standard spect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com