A composition for replacing gelatin to prepare enteric capsule material and its preparation method

A material composition and enteric-coated capsule technology, applied in the field of biomedicine, can solve the problems of unstable quality of gelatin enteric-coated capsules, large quality differences within capsule batches, etc., and achieve the effects of overcoming poor performance of mixed materials and saving processes and costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

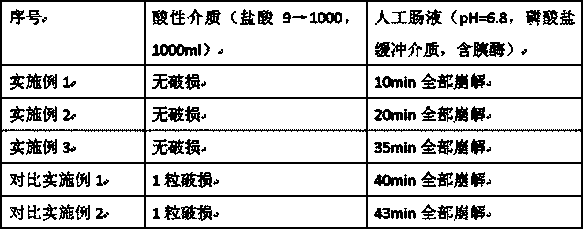

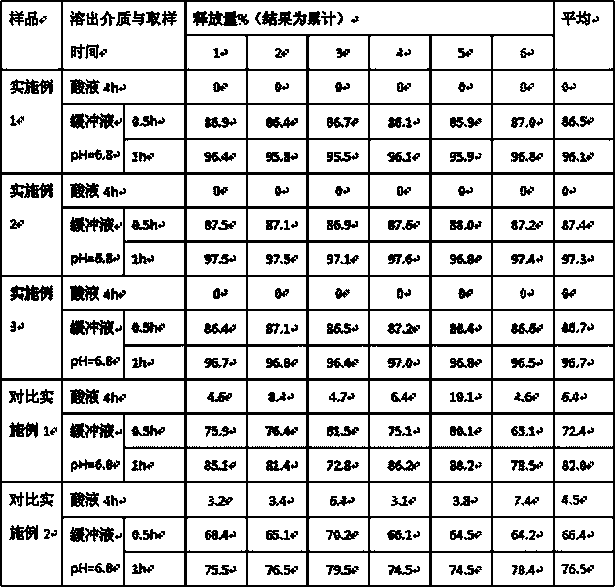

Examples

Embodiment 1

[0029] (1) Take 0.8 parts of starch and 0.4 parts of gelatin, add an appropriate amount of water to dissolve and make 1000ml of a solution with a mass concentration of 25%, add 200ml of 5% glutaraldehyde solution, stir and mix at 75°C to obtain liquid A;

[0030] (2) Take 1.1 parts of chitosan and 0.6 parts of gelatin, add an appropriate amount of 1% hydrochloric acid aqueous solution to dissolve and make 1000ml of a solution with a mass concentration of 25%, add 200ml of 5% glutaraldehyde solution, stir and mix at 70°C to obtain liquid B;

[0031] (3) Mix liquid A and liquid B, then add 0.7 parts of gelatin and 0.8 parts of ammonia water, and mix thoroughly at 70°C to obtain liquid C;

[0032] (4) Pour liquid C into a stainless steel flat tray while it is hot, spread it flat, the thickness of the liquid layer is 1-2cm, send it into a vacuum oven, and dry it at 50°C for 4 hours;

[0033] (5) After drying, take out the tray, peel off the solid inside the tray, crush and sieve t...

Embodiment 2

[0035] (1) Take 1.2 parts of starch and 0.3 parts of gelatin, add an appropriate amount of water to dissolve and make 1000ml of a solution with a mass concentration of 25%, add 3% EDC solution and stir 300ml at 75°C to obtain liquid A;

[0036] (2) Take 0.8 parts of chitosan and 0.5 parts of gelatin, add an appropriate amount of 1% hydrochloric acid aqueous solution to dissolve and make 1000ml of a solution with a mass concentration of 25%, add 200ml of 5% EDC solution, stir and mix at 70°C to obtain liquid B;

[0037] (3) Mix liquid A and liquid B, then add 0.7 parts of gelatin and 0.5 parts of potassium hydroxide, and mix thoroughly at 70°C to obtain liquid C;

[0038] (4) Pour liquid C into a stainless steel flat tray while it is hot, spread it flat, the thickness of the liquid layer is 1-2cm, send it into a vacuum oven, and dry it at 50°C for 4 hours;

[0039] (5) After drying, take out the tray, peel off the solid in the tray, crush and sieve to make

Embodiment 3

[0041] (1) Take 1 part of starch and 0.4 part of gelatin, add an appropriate amount of water to dissolve and make 1000ml of a solution with a mass concentration of 25%, add 200ml of 2% genipin solution, stir and mix at 75°C to obtain liquid A;

[0042] (2) Take 1 part of chitosan and 0.5 part of gelatin, add an appropriate amount of 1% hydrochloric acid aqueous solution to dissolve and make 1000ml of a solution with a mass concentration of 25%, add 200ml of 2% genipin solution, stir and mix at 70°C to obtain liquid B;

[0043] (3) Mix liquid A and liquid B, then add 0.8 parts of gelatin, 2% genipin solution, 0.34 parts of sodium dihydrogen phosphate, 0.36 parts of sodium monohydrogen phosphate, and mix thoroughly at 70°C to obtain liquid C;

[0044] (4) Pour liquid C into a stainless steel flat tray while it is hot, spread it flat, the thickness of the liquid layer is 1-2cm, send it into a vacuum oven, and dry it at 50°C for 4 hours;

[0045] (5) After drying, take out the tray,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com