Preparation method of Cu, Fe-doped vacancy Keggin type silicon tungsten polyoxometallate catalyst

A technology of silicotungstate and catalyst, which is applied in the direction of oxidative preparation of carbonyl compounds, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., which can solve the problems of low recycling rate, low catalytic activity and stable Poor performance and other problems, to achieve the effects of short production cycle, improved catalytic efficiency, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh K 8 [β 2 -SiW 11 o 39 ]·14H 2 O white powder 3.24 g (1 mmol), dissolved in 20 ml deionized water to form solution A, weighed CuCl 2 2H 2 O0.068 g (0.4 mmol) was dissolved in 10 ml deionized water to form solution B, and solution B was slowly added dropwise to solution A to form solution C, which was slowly added dropwise to avoid precipitation during the process;

[0028] (2) Use 4 mol / L HCl solution to adjust the pH of solution C to 5.0, stir at room temperature for 3 h, use 4 mol / L HCl solution to maintain the pH of solution C at 4-6 during the process, and then Slowly evaporate the solution C to dryness, there is solid powder to separate out, continue heating until the quality is constant and does not become the catalyst precursor;

[0029] (3) Put the catalyst precursor in the muffle furnace, under N 2 Calcined at 320 °C for 12 h under protection, and ground the obtained solid into powder to obtain catalyst S1;

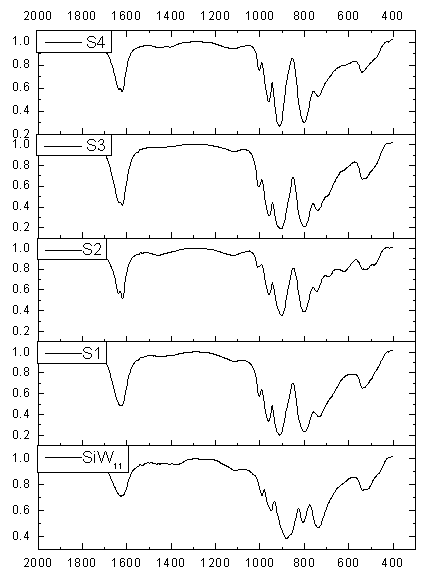

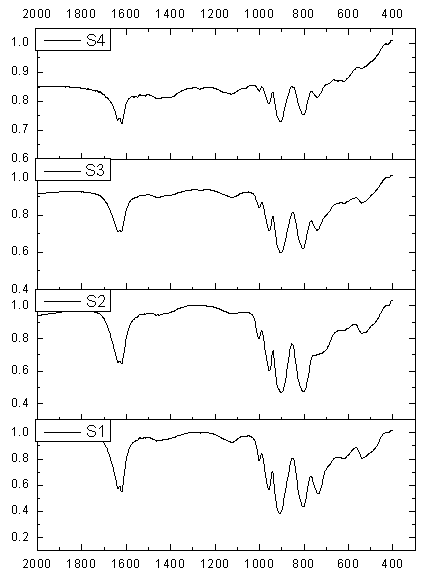

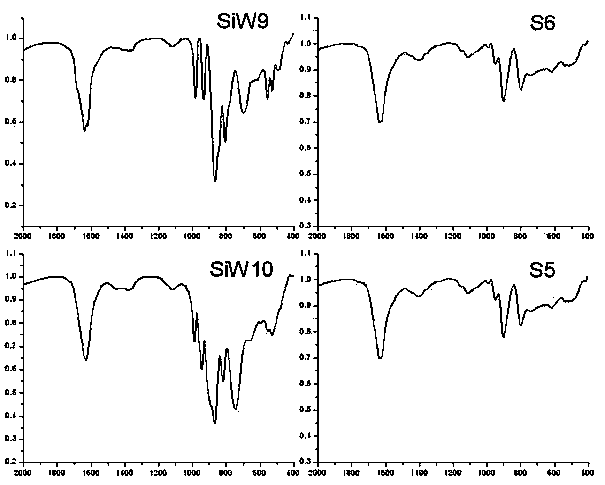

[0030] (4) by figure 1 and Figur...

Embodiment 2

[0032] (1) Weigh K 8 [β 2 -SiW 11 o 39 ]·14H 2 O white powder 3.24 g (1 mmol), dissolved in 20 ml deionized water to form solution A, weighed anhydrous FeCl 3 Dissolve 0.064 g (0.4 mmol) in 10 ml of deionized water to form solution B, slowly add solution B to solution A to form solution C, and add slowly to avoid precipitation during the process;

[0033] (2) Use 4 mol / L HCl solution to adjust the pH of solution C to 5.0, stir at room temperature for 3 h, use 4 mol / L HCl solution to maintain the pH of solution C at 4-6 during the process, and then Slowly evaporate the solution C to dryness, there is solid powder to separate out, continue heating until the quality is constant and does not become the catalyst precursor;

[0034] (3) Put the catalyst precursor in the muffle furnace under N 2 Calcined at 320 °C for 12 h under protection, and ground the obtained solid into powder to obtain catalyst S2;

[0035] (4) by figure 1 and Figure 4 It can be seen that the catalyst...

Embodiment 3

[0037] (1) Weigh K 8 [β 2 -SiW 11 o 39 ]·14H 2 O white powder 3.24 g (1 mmol), dissolved in 20 ml deionized water to form solution A, weighed CuCl 2 2H 2 O0.068 g (0.4 mmol) was dissolved in 10 ml deionized water to form solution B, and anhydrous FeCl was weighed 3 Dissolve 0.064 g (0.4 mmol) in 10 ml deionized water to form solution C, slowly add solutions B and C to solution A respectively to form solution D, and do not precipitate during the dropping process;

[0038] (2) Use 4 mol / L HCl solution to adjust the pH of solution D to 5.5, stir at room temperature for 3 h, use 4 mol / L HCl solution to maintain the pH of solution D at 4-6 during the process, and then Slowly evaporate the solution D to dryness, there is solid powder to separate out, continue heating until the mass is constant and does not become the catalyst precursor;

[0039] (3) Put the catalyst precursor in the muffle furnace under N 2 Calcined at 380 °C for 8 h under protection, and the obtained solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com