Component-controllable copper sulfur selenium nanometer sheet as well as preparation method and application thereof

A technology of selenium nanometer and copper sulfur, which is applied in the field of nanomaterials, can solve the problems of high temperature treatment and complicated process in the preparation method, and achieves the effects of excellent electrical and optical properties, simple process and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

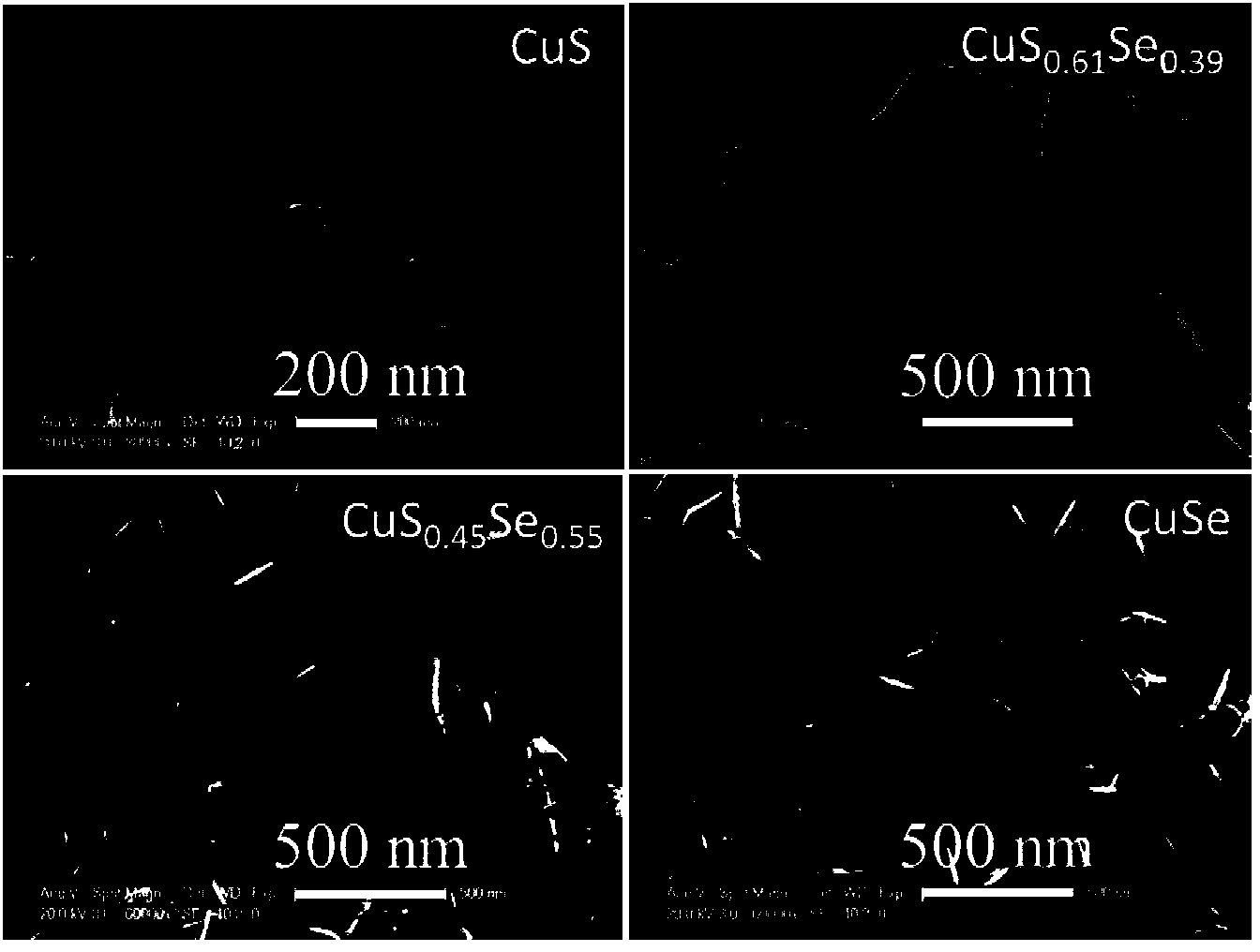

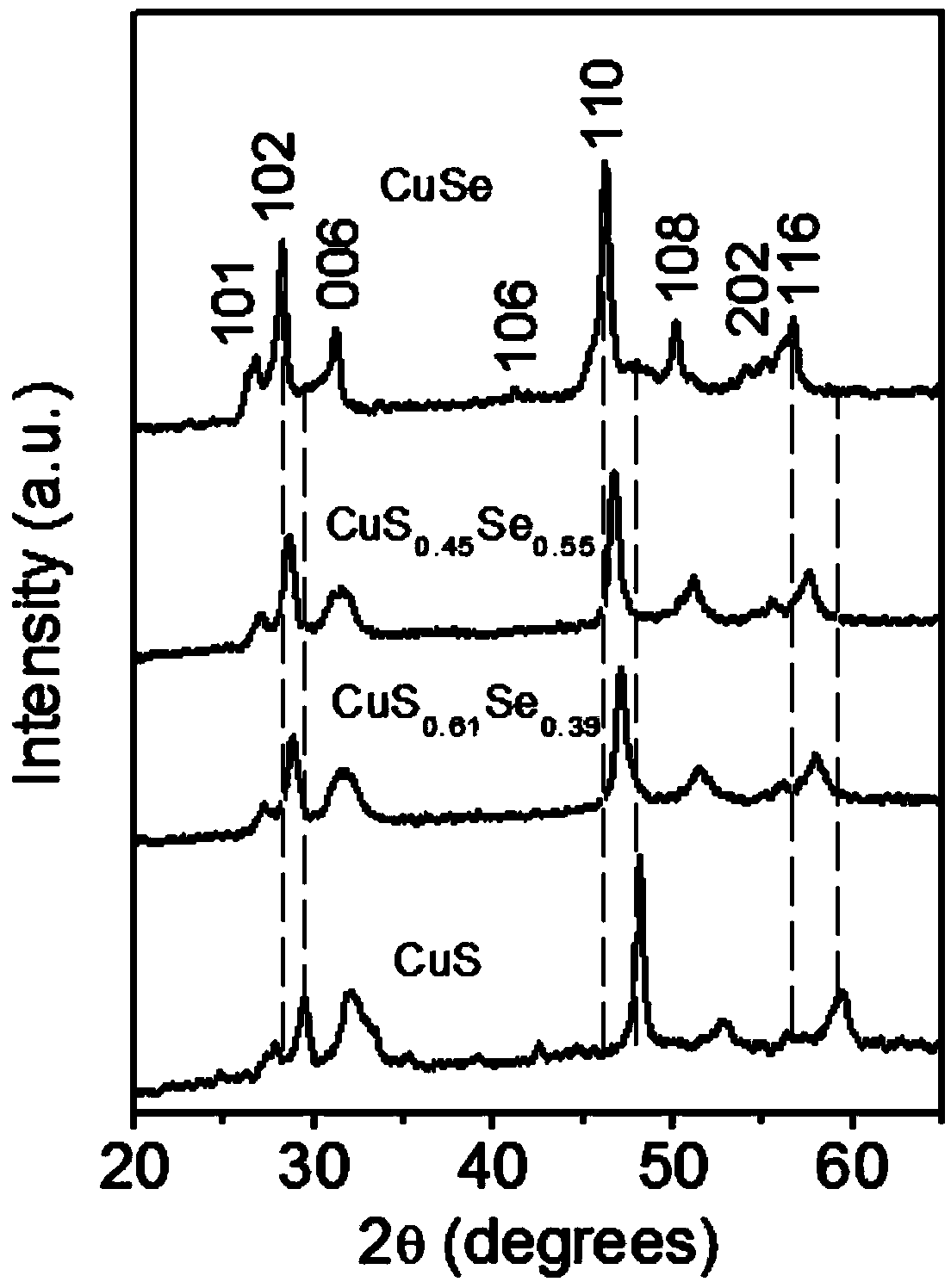

[0030] This embodiment prepares CuS according to the following steps x Se 1-x (0≤x≤1) nanosheets:

[0031] a, weigh or measure each raw material according to Table 1: wherein S powder is selected from (Shanghai Runjie Chemical Reagent Co., Ltd.), analytically pure (>99.9%); Se powder is selected from (Aladdin), purity (>99.9%) ).

[0032] Table 1

[0033] Example

S powder

Se powder

NaOH aqueous solution (5M)

Cu(NO 3 ) 2 (0.2M)

1

2.0mmol

0mmol

20ml

4ml

2

1.0mmol

1.0mmol

20ml

4ml

3

0.75mmol

1.25mmol

20ml

4ml

4

0mmol

2.0mmol

20ml

4ml

[0034] b. Add S powder and Se powder into NaOH aqueous solution, and stir at 90°C for 20 minutes to obtain a mixed solution; when stirring, cover the beaker where the solution is placed with a glass dish to prevent the solution from volatilizing;

[0035] c. Add Cu(NO 3 ) 2 , heated at 90°C for 50 minutes, the result...

Embodiment 5

[0048] This embodiment prepares CuS according to the following steps x Se 1-x Nanosheets:

[0049] a. Weigh 1.25mmol each of S powder and Se powder, add them into 22mL of 4M NaOH aqueous solution, and stir at 80°C for 30 minutes to obtain a mixed solution; when stirring, cover the beaker where the solution is placed with a glass dish to Prevent the solution from volatilizing;

[0050] b. Add 5 mL of CuCl with a concentration of 0.15M to the mixture 2 Aqueous solution, heated at 80°C for 360 minutes, the resulting black precipitate is the initial product;

[0051] c. The initial product was washed several times with deionized water, dilute hydrochloric acid and absolute ethanol in sequence, and then dried at 50°C for 18 hours to obtain the target product CuS 0.65 Se 0.35 Nanosheets.

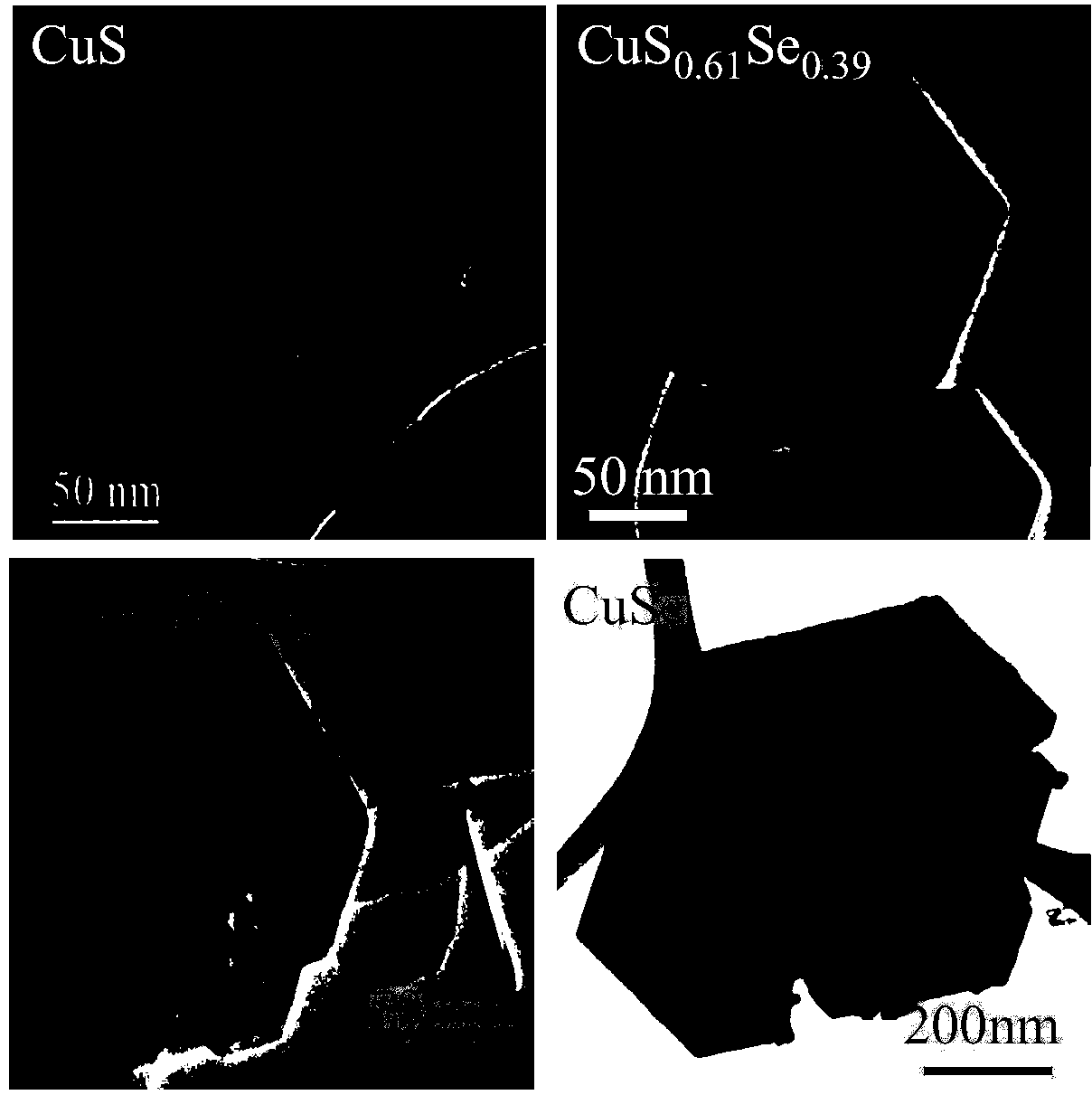

[0052] Through characterization, it can be seen that the diameter of the obtained product is 150 nm, and its morphology is also a hexagonal crystal structure.

Embodiment 6

[0054] This embodiment prepares CuS according to the following steps x Se 1-x Nanosheets:

[0055] a. Weigh 0.75mmol each of S powder and Se powder, add them to 18mL of 6M NaOH aqueous solution, and stir at 100°C for 5 minutes to obtain a mixed solution; when stirring, cover the beaker where the solution is placed with a glass dish to Prevent the solution from volatilizing;

[0056] b. Add 3 mL of copper source solution (CuCl 2 or CuSO 4 After mixing according to the mass ratio of 1:1, add water), and obtain a black precipitate which is the initial product;

[0057] c. The initial product was washed several times with deionized water, dilute hydrochloric acid and absolute ethanol in sequence, and then dried at 70°C for 12 hours to obtain the target product CuS 0.58 Se 0.42 Nanosheets.

[0058] Through characterization, it can be seen that the diameter of the obtained product is 180 nm, and its morphology is a hexagonal crystal structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com