A kind of anisotropic piezoelectric ceramic material and preparation method thereof

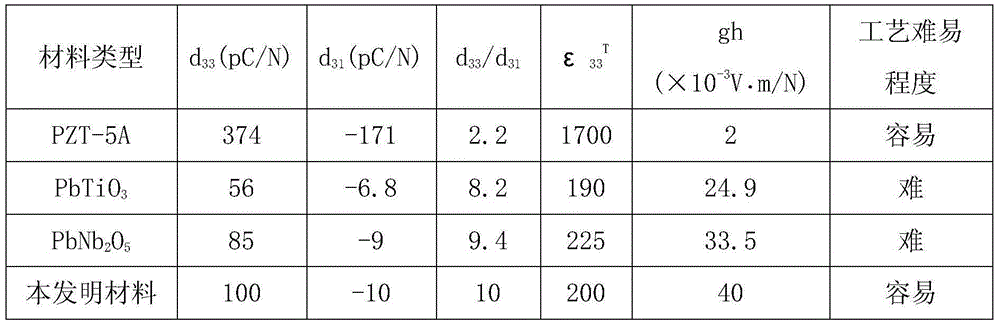

A piezoelectric ceramic and anisotropic technology, applied in the field of sensors, can solve the problems of demanding firing and polarization processes, difficulties in making lead metaniobate materials, difficulties in firing lead titanate materials, etc., and achieve easy organization of production , good and reliable performance, large anisotropy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

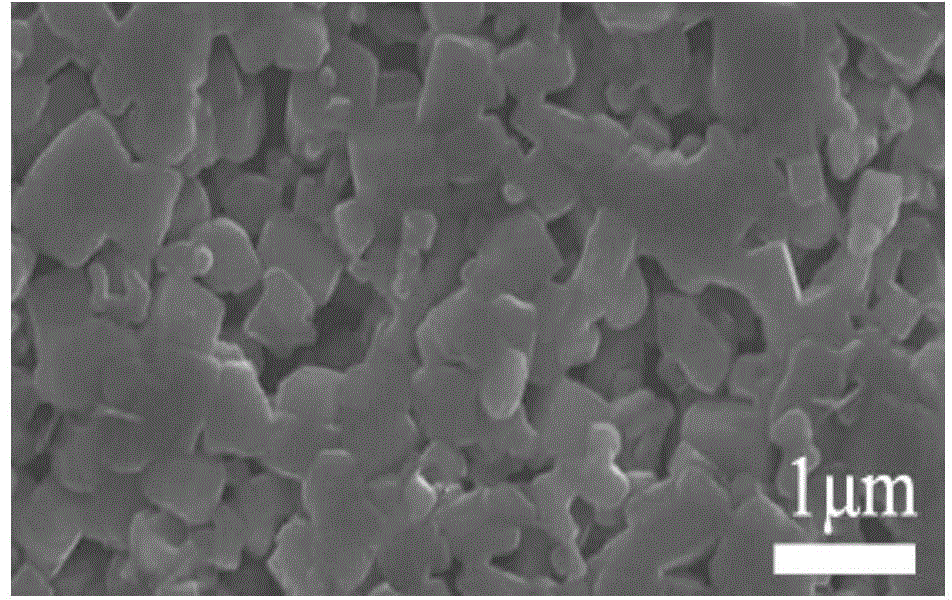

Image

Examples

Embodiment 1

[0033] Embodiment 1: Composition I by material:

[0034] [0.75(0.7PbZrO 3 -0.3K 0.5 Bi 0.5 TiO 3 )-0.25PbTiO 3 ]+0.01PbZnNb 2 o 5 Carry out batching, weigh corresponding analytically pure raw material Pb 3 o 4 , ZrO 2 、KCO 3 、 Bi 2 o 3 、TiO 2 , ZnO, Nb 2 o 5 , put it into a ball mill jar, the ball mill medium is alcohol and zirconia balls, the weight ratio of material: ball: alcohol is 2:1:0.5, the ball mill is 3h, the speed is 600 rpm, after drying the mixture, put it into After compacting in the corundum crucible, cover and seal it, raise the temperature in a muffle furnace at a rate of 100°C / min, keep it at a synthesis temperature of 850°C for 2 hours, then take it out and drop it to room temperature; After crushing and grinding, put it into a ball mill tank for secondary ball milling. The ball milling medium is water and zirconia balls. The weight ratio of material: balls: water is 2:1:1. Ball milling is carried out at a speed of 300 rpm for 12 hours. After...

Embodiment 2

[0035] Embodiment 2: Composition II by material:

[0036] [0.73(0.7PbZrO 3 -0.3K 0.5 Bi 0.5 TiO 3 )-0.27PbTiO 3 )+0.12PbZnNb 2 o 5 Carry out batching; sintering conditions are: first increase to 1220°C at a speed of 5°C / min, and after holding for 10 minutes, drop to 1100°C and hold for 20 minutes; polarization conditions are: in methyl silicone oil at 50°C, apply high-voltage DC voltage 2000V / mm, the polarization time is 30 minutes; the rest of the process is the same as in Example 1; the performance of the element tested after placing it for 48 hours is: relative permittivity ε 33 T =198,d 33 =102pC / N,d 31 =10pC / N,d 33 / d 31 =10.2, g h =41.4×10 -3 V·m / N.

Embodiment 3

[0037] Embodiment 3: Composition III by material

[0038] [0.70(0.7PbZrO 3 -0.3K 0.5 Bi 0.5 TiO 3 )-0.30PbTiO 3 ]+0.20PbZnNb 2 o 5 Carry out batching; the sintering condition is to first raise to 1200°C at a speed of 8°C / min, and then keep it warm for 10 minutes, then lower it to 1100°C and keep it for 30 minutes; the polarization condition is: in methyl silicone oil at 50°C, apply a high voltage DC voltage of 2000V / mm, the polarization time is 30 minutes; all the other processes are the same as in embodiment 1; the performance of the element tested after placing for 48 hours is: relative permittivity ε 33 T =240, d 33 =120pC / N,d 31 =28pC / N,d 33 / d 31 =4.3, gh=30×10 -3 V·m / N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com