Organic semiconductor material, preparation method and electroluminescent device

A technology of electroluminescent devices and organic semiconductors, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, organic compound preparation, etc., can solve problems such as shortages, and achieve the effects of reduced manufacturing costs, reduced process flow, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention provides a method for preparing an organic semiconductor material, including the following steps:

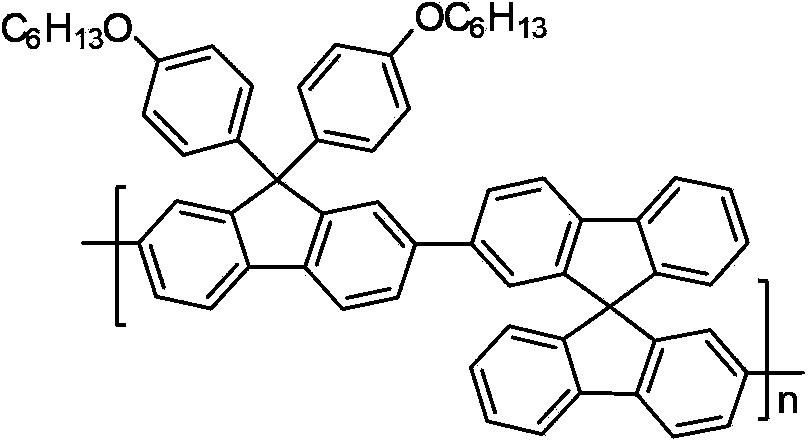

[0026] Provide compound A: And compound B: Where R is C 1 ~C 20 In an inert atmosphere, compound A and compound B are added into an organic solvent containing a catalyst and an alkali solution in a molar ratio of 1:1 to 1:1.2, and the Suzuki coupling reaction is carried out at 70 to 130 ℃ 12~ For 96 hours, the catalyst is organopalladium or a mixture of organopalladium and organophosphorus ligand, to obtain an organic semiconductor material P represented by the following structural formula:

[0027] Wherein, n is an integer from 10 to 100.

[0028] In a specific embodiment, the method for preparing the organic semiconductor material further includes a step of separating and purifying the organic semiconductor material P, and the step of separating and purifying is as follows: the compound A and the compound B are subjected to the Suzuki coupling reaction...

Embodiment 1

[0041] This embodiment discloses poly{2,7-diyl-9,9-bis(4-n-hexaneoxybenzene) fluorene-co-2,2'-diyl-9,9'-spiro two with the following structural formula Fluorene} (organic semiconductor material P1):

[0042]

[0043] The preparation process of the above organic semiconductor material P1 is as follows:

[0044] Under the protection of argon, 9,9-bis(4-n-hexaneoxybenzene) fluorene-2,7-dipinacol borate (154mg, 0.2mmol), 2,2'dibromo-9, 9'-Spirobifluorene (95mg, 0.2mmol) was added to the flask containing 10ml of toluene solvent, after fully dissolved, potassium carbonate (2mL, 2mol / L) solution was added to the flask, vacuumed to remove oxygen and filled with argon , Then add bistriphenylphosphine palladium dichloride (5.6mg, 0.008mmol); heat the flask to 100°C for Suzuki coupling reaction for 48h. After cooling, the polymerization reaction was stopped, and 50ml methanol was added dropwise to the flask for sedimentation; after filtering through a Soxhlet extractor, it was extracted wit...

Embodiment 2

[0053] This embodiment discloses poly{2,7-diyl-9,9-bis(4-methoxybenzene)fluorene-co-2,2'-diyl-9,9'-spirobifluorene with the following structural formula } (Organic Semiconductor Material P2):

[0054]

[0055] Under the protection of a mixture of nitrogen and argon, 9,9-bis(4-methaneoxybenzene) fluorene-2,7-dipinacol borate (189mg, 0.3mmol), 2,2'dibromo -9,9'-spirobifluorene (142mg, 0.3mmol) and 15mL of tetrahydrofuran were added to a 50mL two-necked flask. After being fully dissolved, a mixture of nitrogen and argon was introduced to exhaust the air for about 20 minutes, and then tetratriphenylene Phosphine palladium (4mg, 0.003mmol) was added to it, and after it was fully dissolved, sodium bicarbonate (3mL, 2mol / L) solution was added. After fully ventilating the mixed gas of nitrogen and argon for about 10 minutes, the two-necked flask was added to 70 ℃ for Suzuki coupling reaction for 96 hours. After cooling down, the polymerization reaction was stopped, and 40ml methanol wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com