A kind of magnesium alloy anode rod processing method

A magnesium alloy anode rod and a processing method technology, applied in the field of material preparation, can solve the problems of long rods, low production efficiency, poor surface finish and the like, and achieve the effects of improved electrochemical performance, high production efficiency, and improved bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

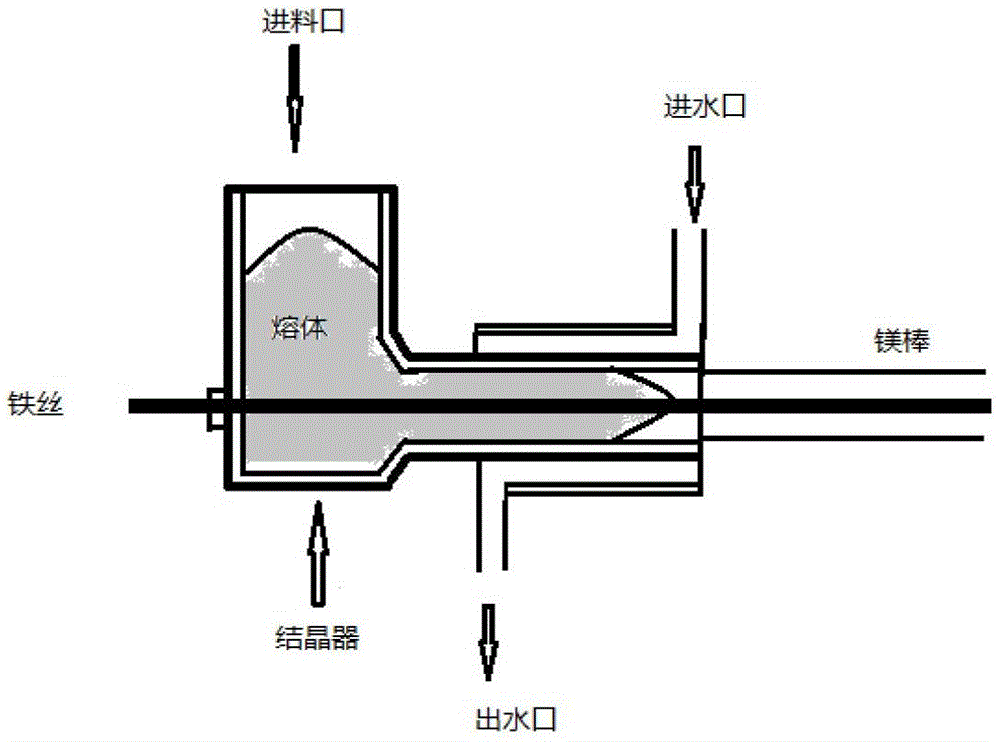

[0015] After the magnesium ingot is melted, raise the temperature to 730°C, add 2.5-3.5wt% Zn and 5.5-6.5wt% Al of the total alloy, and stir for 20-25 minutes after they are fully melted, 720-730 ℃ range for 30 minutes, then remove the slag from the bottom of the pot; when the temperature of the alloy melt drops to 670 ℃, keep warm and carry out electromagnetic stirring for 20 minutes; heat the iron wire with a diameter of 3mm at 400 ℃ to melt the above The body is poured into the crystallizer, and the iron wire is pulled at the same time. The melt solidifies around the iron wire at the water-cooled end to form an AZ63 anode rod with an outer diameter of 22mm, such as figure 1 shown.

[0016] For the above AZ63 magnesium alloy anode rods, equipped with two people for drawing casting and two people for mold pouring, working for eight hours, the drawing casting produces about 512m of AZ63 alloy rods, and the product pass rate is over 98%; the mold pouring is about 49m, and the p...

Embodiment 2

[0018] After the magnesium ingot is melted, raise the temperature to 740°C, add 2.5~3.5wt% Zn and 5.5~6.5wt% Al of the total amount of the alloy, and stir for 30~35 minutes after they are fully melted, 720~730 Stand still within the range of ℃ for 35 minutes, and remove the slag; when the temperature of the alloy melt drops to 690 ℃, keep warm and carry out electromagnetic stirring for 25 minutes; heat the iron wire with a diameter of 3 mm at 450 ℃, inject the above alloy melt into the crystallizer, and The iron wire is pulled, and the melt solidifies around the iron wire at the water-cooled end to form an AZ63 anode rod with an outer diameter of 22mm, such as figure 1 shown.

[0019] For the above AZ63 magnesium alloy anode rods, equipped with two people for drawing casting, two people for mold casting, three people for drawing casting, and three people for mold casting, working for eight hours, the drawing casting will produce about 768m of AZ63 alloy rods, and the product q...

Embodiment 3

[0021] After the magnesium ingot is melted, raise the temperature to 735°C, add 2.5~3.5wt% Zn and 5.5~6.5wt% Al of the total amount of the alloy, respectively, and stir for 25 minutes after they are fully melted. Set aside for 30-35 minutes, remove the slag; keep warm at 670-690°C and carry out electromagnetic stirring for 22 minutes; heat the iron wire with a diameter of 3mm at 400°C, pour the above alloy melt into the crystallizer, and pull the iron wire at the same time, and the melt is in the The water-cooled end solidifies around the iron wire to form an AZ63 anode rod with an outer diameter of 22mm, such as figure 1 shown.

[0022] For the above AZ63 magnesium alloy anode rods, equipped with 4 people for drawing casting and 4 people for mold pouring, and working for eight hours, the drawing casting will produce about 1018m of AZ63 alloy rods, and the product pass rate is over 96%; the mold pouring is about 95m, and the product pass rate is about 73% %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com