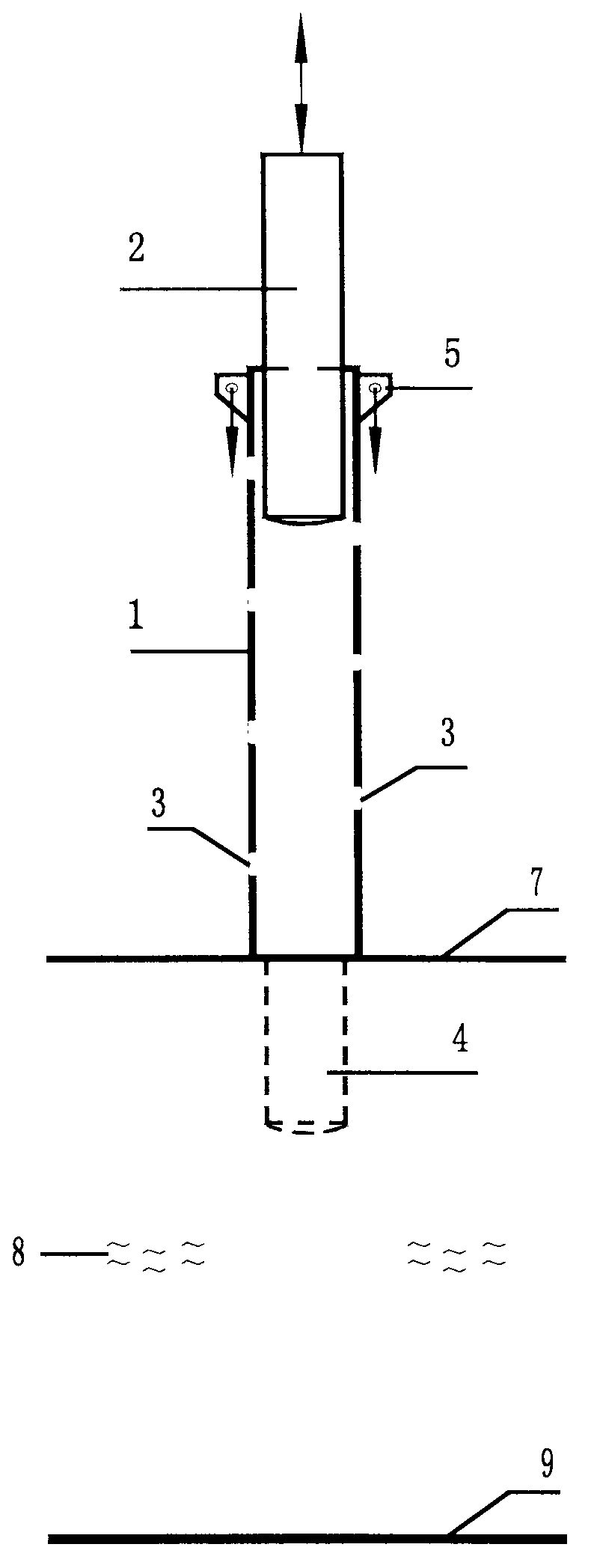

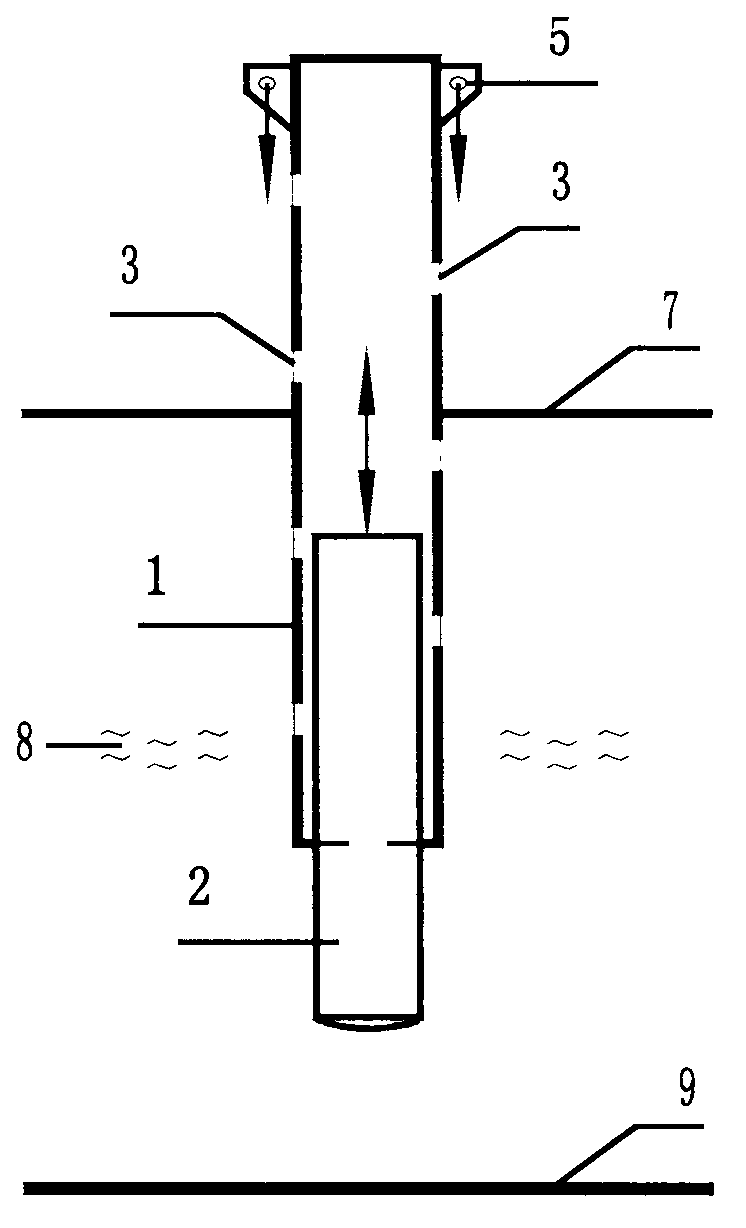

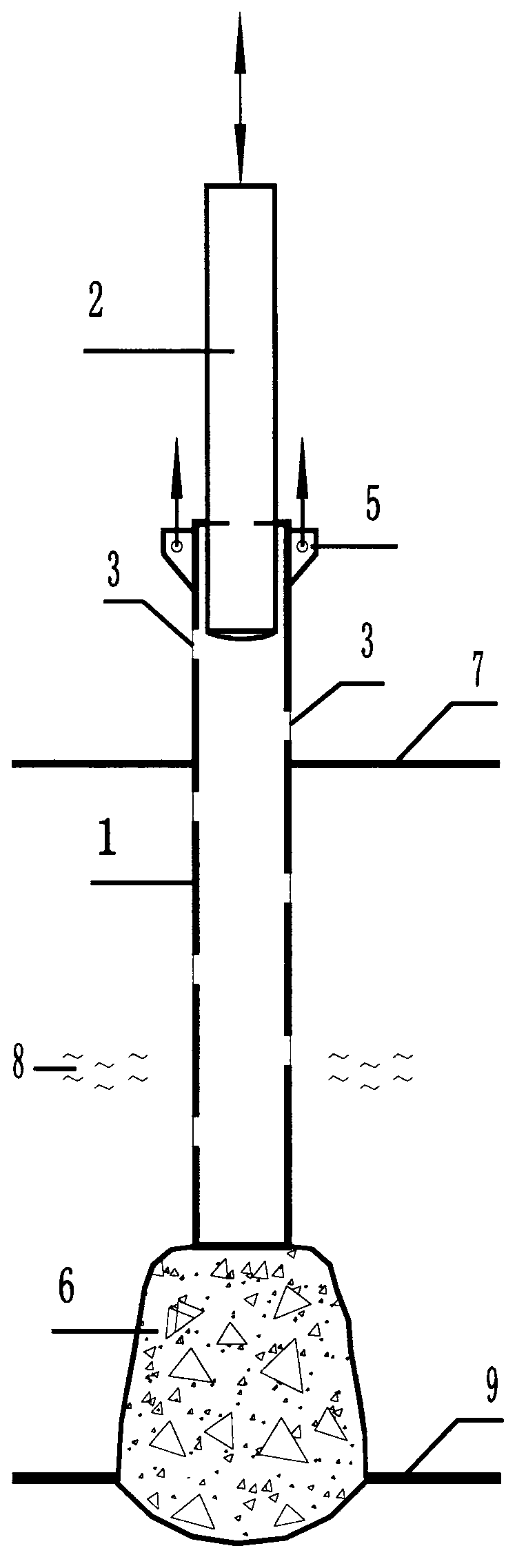

Construction method for composite foundation on soft soil stratum

A composite foundation and construction method technology, applied in soil protection, infrastructure engineering, construction and other directions, can solve the problems of high construction cost, large construction noise, large environmental impact, etc., to achieve good water permeability and reduce investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] An industrial warehouse with an area of 20,000m 2 , single-layer light steel structure. Geological conditions: silt 18-20m below the natural ground, characteristic value of foundation soil bearing capacity f ak =40kPa,E s =1.44MPa; the bearing layer is silt soil, and the characteristic value of bearing capacity of foundation soil f ak =190kPa,E s = 10.49MPa. The characteristic value f of the bearing capacity of the foundation soil below the floor is required by the design ak = 100kPa.

[0044] The original plan: set up concrete caps of 6*6 meters, set 4 Φ600 prestressed pipe piles under each cap, the pile length is 30m, and set primary and secondary beams and 180 thick reinforced concrete floor slabs on the caps.

[0045] In this plan, Φ1200~1500~2500 reinforcements are used to arrange the reinforcements, the pile length is 18~20m, and the piles are arranged in an equilateral triangle; the triangle center is set to Φ1200, and the pile length is 8m, and one reinf...

Embodiment 2

[0047] A certain 50,000 m 3 Oil tank foundation, diameter Φ60m. Geological conditions: silty clay 20m below the natural ground, no hard crust, characteristic value of foundation soil bearing capacity f ak =45kPa,E s =3.14MPa; the bearing layer is silty clay, and the characteristic value of bearing capacity of foundation soil f ak =180kPa, E s = 3.62MPa. The characteristic value f of the bearing capacity of the foundation soil below the foundation is required by the design ak = 250kPa.

[0048] The original plan: According to Φ600 prestressed pipe piles, the pile length is 36m, and the piles are spread all over the house.

[0049] In this plan, Φ1800~2500 reinforcements are used, and piles are spread all over the house; reinforcements are arranged between tanks and around them according to Φ1500-1500, and the pile length is 20m. After the construction is completed, it will be replaced by dynamic tamping; the processing results have been tested, and the characteristic val...

Embodiment 3

[0051] Geological conditions of an airport runway: There are 8-15m thick clayey silts under the plain fill, 5-8m thick collapsible loess under this layer, and the bearing layer is a relatively good soil layer. This scheme first adopts the method of introducing holes, then back-presses the casing above the bearing layer, feeds and rams and fills solid materials, and after replacing the collapsible loess layer, lifts the casing while feeding and tamping, and then inserts the hole Partially compacted. This scheme has the best effect in dealing with the sandwich layer of soft soil foundation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Pile length | aaaaa | aaaaa |

| Carrying capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com