Method for detecting content of antimony in liquid product

A detection method, liquid technology, applied in the field of chemical analysis, can solve the problems of high cost and complicated operation, and achieve the effect of high selectivity and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

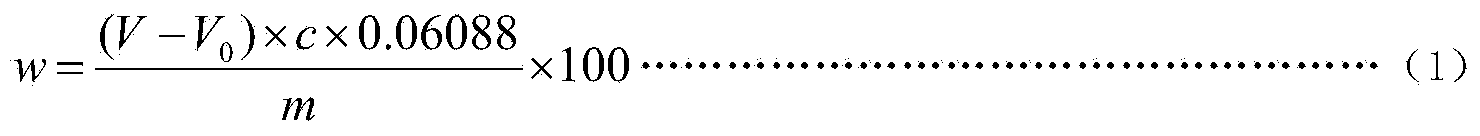

Method used

Image

Examples

Embodiment 1

[0042]A. Accurately weigh 0.65g (± 0.0001g) samples of antimony-containing metal passivators (used in catalytic cracking units, antimony is +5, numbered 1#) and place them in three 250ml cones bottle (take two 250ml Erlenmeyer flasks for blank test at the same time), add 20ml 98% sulfuric acid each time to dissolve the sample, control the appropriate temperature (110-115°C), add 3 drops (about 1 g ) 98% nitric acid, shake well for digestion and oxidation, cool to 40°C, add (1.5±0.1) g of urea, shake well, heat until no white smoke is produced, cool to below 40°C, add (0.5±0.1) g of masking agent thiourea , Rinse the wall of the bottle with (10±1)mL of 98% sulfuric acid, shake well and heat until no small bubbles are generated, cool to below 40°C and slowly add (100±1)ml of deionized water and shake slowly, then add (20 ±1)ml 37% hydrochloric acid, shake well, boil and keep boiling slightly for 2-3min, cool to 65-75℃ for test;

[0043] B. Determination of antimony content in s...

Embodiment 2

[0046] A. Accurately weigh 0.75g (± 0.0001g) sample of 4% ethylene glycol antimony ethylene glycol solution (for polyester preparation equipment, antimony is +3 valence, number 2#) mixed uniformly in three In one 250ml conical flask (take two 250ml conical flasks for blank test at the same time), add 20ml of 98% sulfuric acid each time to dissolve the sample, control the appropriate temperature (110-115°C), add 3 drops with a dropper while it is hot (about 1 gram) 98% nitric acid, shake well for digestion and oxidation, cool to 40°C, add (1.5±0.1) g of urea, shake well, heat until no white smoke is produced, cool to below 40°C, add (0.5±0.1) g of urea For the masking agent thiourea, wash the bottle wall with (10±1)mL of 98% sulfuric acid, shake well and heat until no small bubbles are generated, cool to below 40°C, slowly add deionized water (100±1)ml and shake slowly, Then add (20±1)ml 37% hydrochloric acid, shake well, boil and keep boiling slightly for 2-3min, cool to 65-75...

Embodiment 3

[0050] A. Accurately weigh 0.95g (±0.0001g) samples of fireproof coating (containing antimony white powder, antimony is +5, number 3#) and place them in three 250ml conical flasks (take three at the same time) 250ml Erlenmeyer flask for blank test), add 20ml 98% sulfuric acid each time to dissolve the sample, control the appropriate temperature (110-115°C), add 3 drops (about 1 gram) 98% nitric acid with a dropper while it is hot and shake well Digest and oxidize, cool to 40°C, add (1.5±0.1) g of urea, shake well, heat until no white smoke occurs, cool to below 40°C, add (0.5±0.1) g of masking agent thiourea, use (10±1) Rinse the wall of the bottle with 98% sulfuric acid in mL, shake well and heat until there are no small bubbles, cool to below 40°C, slowly add (100±1)ml of deionized water and shake well, then add (20±1)ml of 37% hydrochloric acid to shake Mix well, boil and keep boiling slightly for 2-3 minutes, cool to 65-75°C for testing;

[0051] B. Determination of antim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com