Magnetic aerogel and preparation method thereof

An aerogel and magnetic technology, applied in chemical instruments and methods, colloidal chemistry, colloidal chemistry, etc., to achieve the effects of good electrical conductivity, large specific surface area, and improved adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

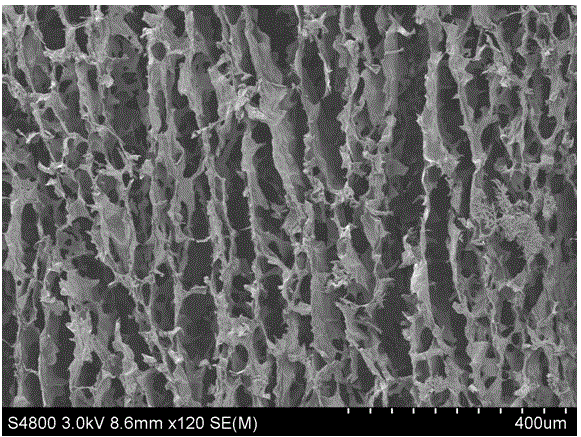

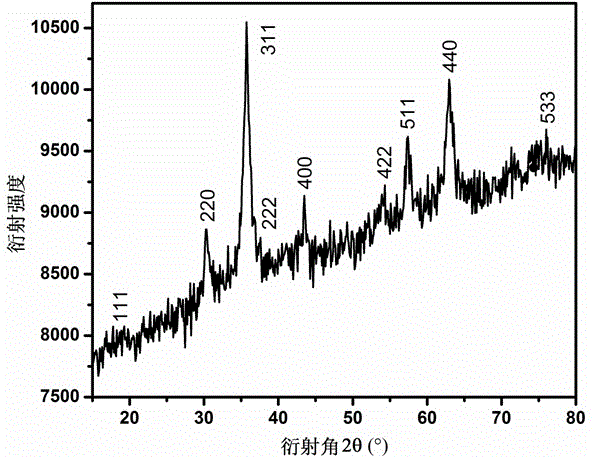

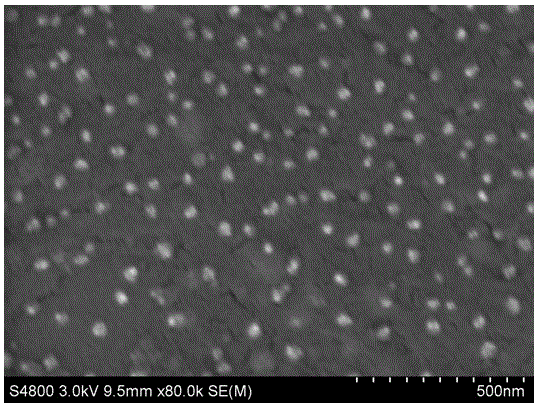

[0027] (1) Put 2g of graphite powder in a third-grade flask, add a mixture of 41.4ml of concentrated sulfuric acid and 4.6ml of phosphoric acid under ice-bath stirring, and after stirring for 15min, slowly add 12g of potassium permanganate to keep the system temperature not higher than 20°C. Stir for 30 minutes; remove the ice bath, place the reaction system in a water bath at 35°C, stir thoroughly for 2 hours, the reactant turns into a dark brown paste; slowly add 20ml of deionized water to the reactant, and control the temperature of the system not to exceed 98°C, when the temperature no longer rises, quickly transfer it to a 98°C water bath and stir for 15 minutes; add 280ml, 50°C deionized water and 20ml 30% hydrogen peroxide to the reactant in turn, and the reactant changes from brown to Bright yellow; after stirring for 5 minutes, take it out and filter while it is hot to obtain a tan filter cake, centrifuge and wash the product 3 times with 300ml and 3% hydrochloric acid...

Embodiment 2

[0035] (1) Put 1g of graphite powder in a third-grade flask, add a mixture of 20.7ml of concentrated sulfuric acid and 2.3ml of phosphoric acid under ice bath stirring, and after stirring for 15min, slowly add 6g of potassium permanganate to keep the system temperature not higher than 20°C. Stir for 30 minutes; remove the ice bath, place the reaction system in a 35°C water bath, stir for 2 hours, and the reactant turns into a dark brown paste; slowly add 10ml of deionized water to the reactant, and control the temperature of the system not to exceed 98°C, when the temperature no longer rises, quickly transfer it to a 98°C water bath and stir for 15 minutes; add 140ml, 50°C deionized water and 10ml 30% hydrogen peroxide to the reactant in turn, and the reactant changes from brown to Bright yellow; after stirring for 5 minutes, take it out and filter while it is hot to obtain a tan filter cake, centrifuge and wash the product 3 times with 150ml of 3% hydrochloric acid, then repea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com