A kind of preparation method of porous composite material

A technology of porous composite materials and composites, which is applied in the field of preparation of new porous composite materials, can solve the problems of non-eutectic porous composite materials, etc., and achieve good adsorption effect and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

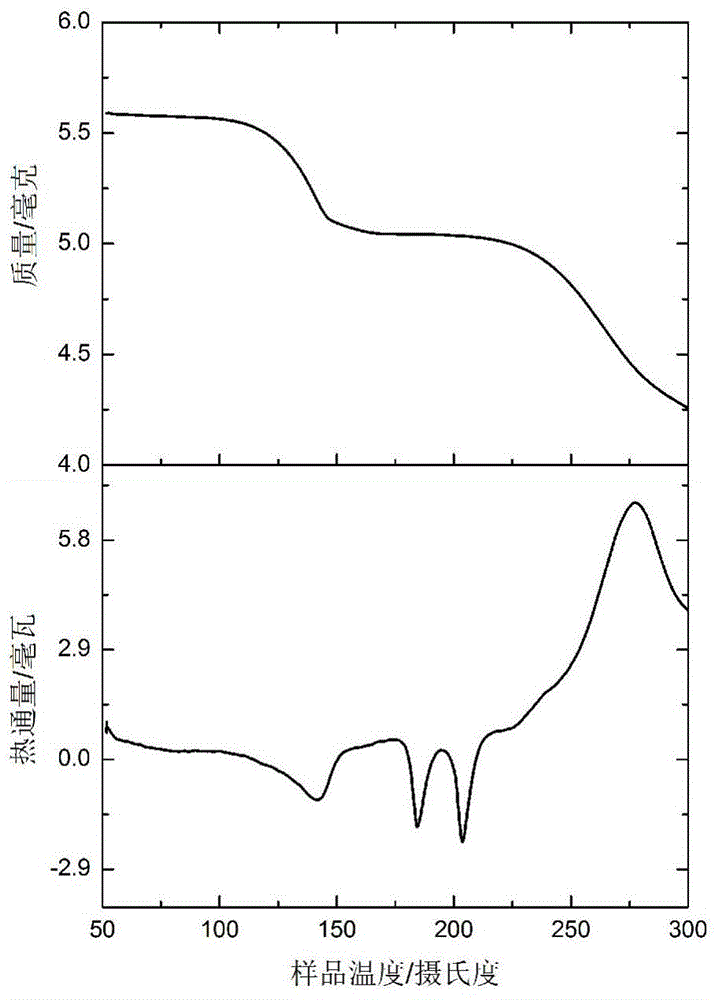

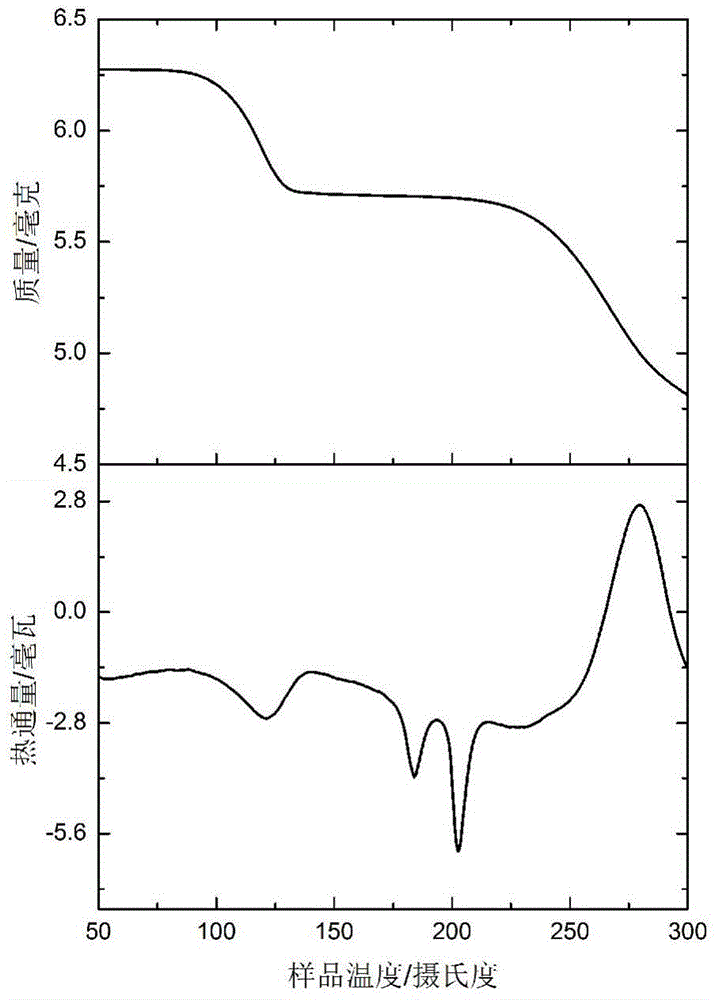

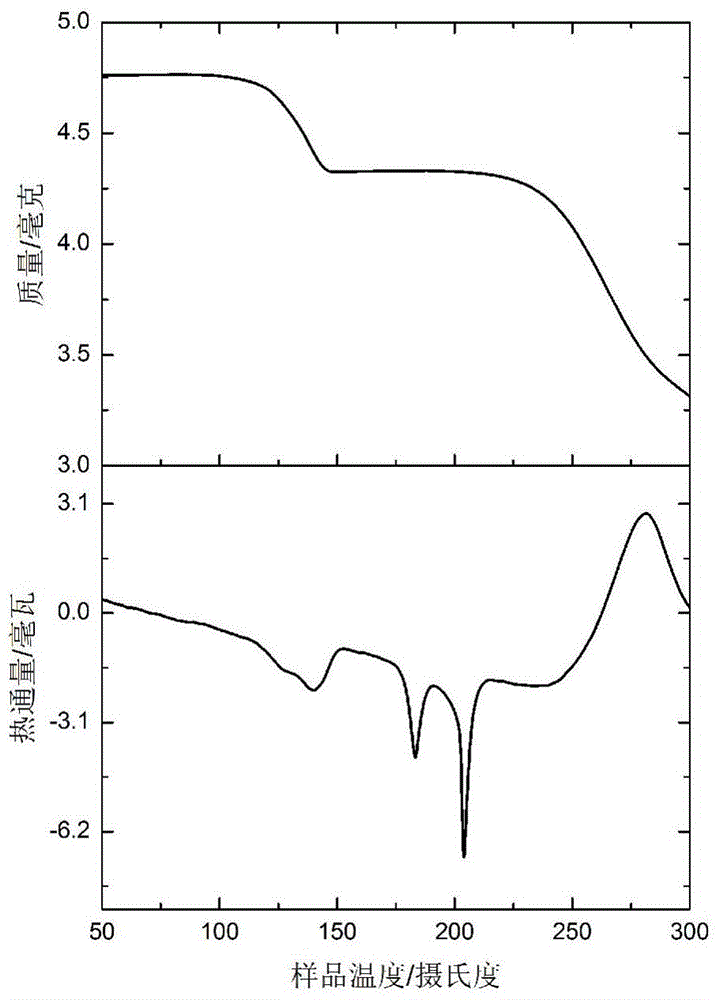

Image

Examples

Embodiment 6

[0030] Example 6 and the comparative example illustrate the adsorption effect of this new porous composite material.

Embodiment 1

[0032] Mix 66.40mg of 3-(pyrene-1-yl)-1-phenylprop-2-en-1-one (chalcone-1) with 40.80mg 7,7,8,8-tetracyanoquinone Methane (TCNQ) was added to the mortar, ground for 30 minutes, and the color changed to dark green to obtain a porous composite material.

Embodiment 2

[0034] Combine 61.60mg 3-(anthracene-9-yl)-1-phenylprop-2-en-1-one (chalcone-2) and 40.80mg 7,7,8,8-tetracyanoquinone Methane (TCNQ) was added to the mortar, 1 mL of methanol was added dropwise to the mortar, and the mortar was ground for 30 min. The color was observed to turn dark green. The ground powder was taken out and dried to obtain a porous composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com