Rare earth doped oxyfluoride near-infrared luminescent glass and preparation method thereof

A technology of oxyfluoride and rare earth doping, which is applied in the field of rare earth doped oxyfluoride near-infrared luminescent glass and its preparation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5 9

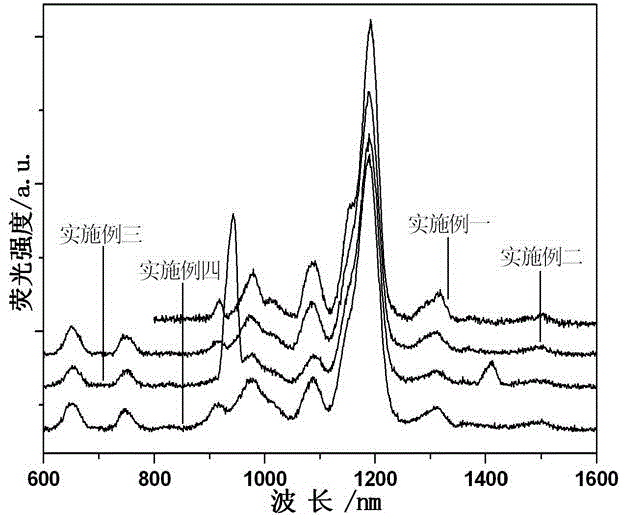

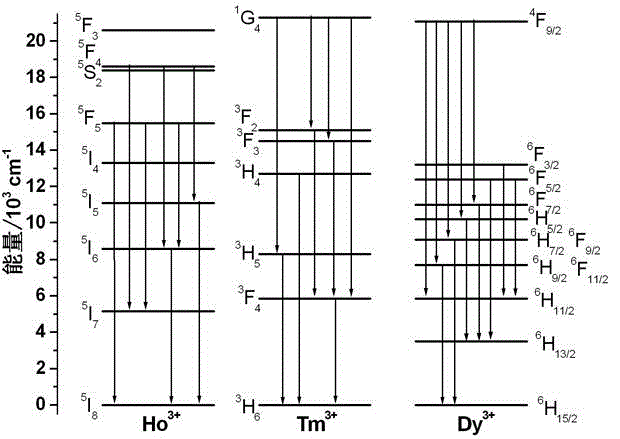

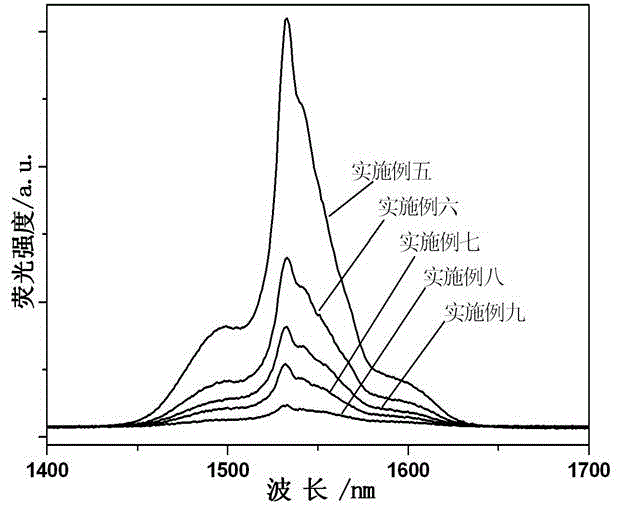

[0048] Accurately weigh each component raw material according to the mole percentage composition of embodiment five to nine glass in table 2, wherein raw material SiO 2 、BaF 2 and ZnF 2 For analytically pure, Er 2 o 3 It is pure 3N5. The raw materials were thoroughly ground and mixed in a mortar, put into a crucible, placed in a muffle furnace, and melted at 1220°C for 1 hour. Pour the molten glass into a preheated mold, anneal at 470°C for 6 hours, and then cool down to room temperature with the furnace. After the prepared glass is cut, ground and polished, the desired sample can be obtained. All samples exhibit near-infrared emission in the range of 1400–1700 nm under excitation at 378 nm (e.g. image 3 shown), whose emission center is located at 1533 nm, corresponding to Er 3+ of 4 I 13 / 2 → 4 I 15 / 2 transitions, and the half-maximum widths were measured to be 31 nm, 39 nm, 44 nm, 42 nm and 41 nm, respectively. It can be seen from the figure that Embodiment 5 pre...

Embodiment 10 14

[0050] Accurately weigh each component raw material according to the mole percentage composition of embodiment ten to fourteen glass in table 3, wherein raw material SiO 2 、BaF 2 and ZnF 2 Analytical pure, Tm 2 o 3 It is pure 3N5. The raw materials were thoroughly ground and mixed in a mortar, put into a crucible, placed in a muffle furnace, and melted at 1220°C for 1 hour. Pour the molten glass into a preheated mold, anneal at 470°C for 6 hours, and then cool down to room temperature with the furnace. After the prepared glass is cut, ground and polished, the desired sample can be obtained. Excite all samples at 357 nm, and measure their fluorescence spectra in the range of 600-1700 nm (such as Figure 5 shown). The results show that Example 10 exhibits the strongest near-infrared emission. In addition, it can be seen from the figure that the sample exhibits fluorescence emission at 660nm, 750nm, 798nm, 1073nm, 1101nm, 1353nm, 1437nm, 1503nm and 1605nm, corresponding t...

Embodiment 15 17

[0052] Accurately weigh each component raw material according to the mole percentage composition of embodiment fifteen to seventeen glass in table 4, wherein raw material SiO 2 、BaF 2 and ZnF 2 Analytical pure, Dy 2 o 3 It is pure 3N5. The raw materials were thoroughly ground and mixed in a mortar, then put into a crucible, placed in a muffle furnace, and melted at 1250°C for 1 hour. Pour the molten glass into a preheated mold, anneal at 500°C for 8 hours, and then cool to room temperature with the furnace. After the prepared glass is cut, ground and polished, the desired sample can be obtained. Excite all samples at 349 nm, and measure their fluorescence spectra in the range of 600-1600 nm (such as Figure 6 shown). The results show that Example 15 presents the strongest near-infrared emission. In addition, it can be seen from the figure that the samples exhibit fluorescence emission at 665nm, 754nm, 848nm, 968nm, 1018nm, 1149nm, 1332nm, 1443nm and 1510nm, correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com